Reports: ND1054109-ND10: Nanostructured Surfaces with Wetting Controllability for Dielectric Liquids for Phase Change Heat Transfer

Renkun Chen, PhD, University of California, San Diego

The goal of the project is to understand and enhance the performance phase change heat transfer of dielectric liquids using advanced nanostructures. To date, we have theoretically studied the effect of nanostructuring design, specifically the nanoporous membrane (NPM) design, for thin film evaporation. We have also designed and fabricated NPMs, and carried out preliminary heat transfer experiments. These experiments showed that we can achieve the theoretically predicted critical heat flux (CHF) of IPA on NPMs.

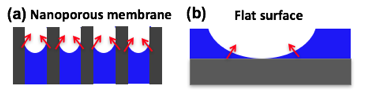

The basic concept of using nanoporous for enhancing evaporative heat transfer is shown in Fig. 1. On a flat surface (Fig. 1(b)), the effective evaporating area is relatively small compared to the overall flat surface area: only the liquid film underneath the so-called evaporation meniscus (arrows in Fig. 1(b)) can evaporate; the thinner and thicker films would not evaporate. In the case of a nanoporous membrane, the ratio between the evaporating area and the projected surface area is greatly enhanced by the three dimensional geometry (Fig. 1(a)).

Fig. 1. Basic concept of using nanoporous membranes to increase the effective evaporating area.

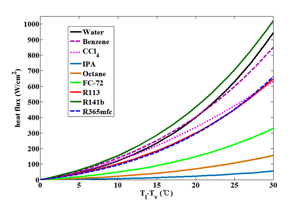

We first modeled the expected thermofluidic performance of the NPMs. We followed the model developed by Lu et al. [1], which takes the rarefied gas effect in the nanopores into account. We further improved the model by considering the actual profile of an evaporating surface in a nanopore, such as the one showing in Fig. 1(a). The CHF occurs when the capillary pumping pressure is balanced by the flow viscous resistance. Through the modeling, we identified the optimal design for the NPMs and the microchannels: the microchannels will have dimensions of ~ 50-100 um while the NPMs have pore sizes of 50-100 nm. This disparity in the dimensions will overcome the conventional tradeoff in wicks based on sintered Cu particles, namely, small feature size for large capillary pumping vs. large size for low fluidic viscous drag. Fig. 2 shows the modeling result on heating power vs. wall superheat for IPA and water. These values are unusually high compared to what have been achieved in boiling and evaporative heat transfer, which shows the great potential of using NPM for enhancing phase change heat transfer.

Fig. 2. Modeling results for evaporation of various fluids through NPMs.

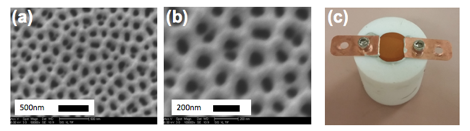

To validate the model and demonstrate the superior performance of the NPMs, we designed and fabricated a test apparatus for the evaporative heat transfer experiments. Fig. 3 shows the test specimen based on anodized aluminum oxide (AAO). The pore size of the AAO ranges from 100 nm to 200 nm (Fig. 3(a) and (b)), and the thickness is about 50-60 um. We deposited a thin layer of metal on top of the AAO membranes to serve as a heater and a thermometer for the heat transfer experiments (Fig. 3(c)), and then mounted the entire sample onto a test fixture with a through hole underneath the AAO membrane. We then mounted the entire test fixture in an evaluated chamber. The hole underneath the sample is connected to a fluidic feed through, from which the liquid is supplied. When doing the heat transfer experiment, we applied a DC current to the sample heater, and determined the heating power by measuring the current and the voltage across the heater. We also measured the temperature of the heater by monitoring the change of the heater resistance.

Fig. 3. Test sample based on AAO membrane (a) & (b), SEM image of the AAO. (c) photograph of a sample mounted onto the test fixture.

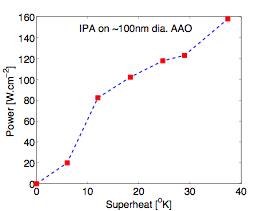

Figure 4 shows the preliminary results we obtained on the evaporation of IPA through NPM. The measurement was done within an evacuated chamber. The heat flux increases with the superheat, and reaches the CHF of close to 160 W/cm2 at superheat of ~37oK. This CHF value is very close to the predicted value shown in Fig. 2, and, to our best knowledge, is the highest reported CHF value for the fluid of IPA. This result shows the great promise of using NPM for high flux evaporative cooling.

Fig. 4. Measured power density vs. superheat for IPA evaporation through AAO.

In view of this promising results, our plan for the next year is to test a variety of fluids and make a high-performance evaporator. Specifically, we will carry out the following tasks.

1. Fabricate Si based NPM through large-scale nano-imprint lithography. The desirable geometry would be ~100 nm pore size and less than 10-um membrane thickness. We have made ~300 pores on large scale Si wafers, and will continue to optimize the process to make NPMs with ~100 nm pores.

2. Fabricate evaporators with NPM and microchannels.

3. Test the performance of the evaporators with a variety of fluids, such as the ones modelled theoretically, as shown in Fig. 2.

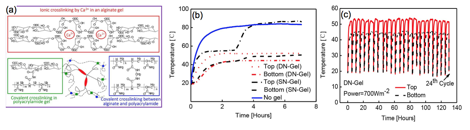

In addition to studying phase change heat transfer through NPM, we also leveraged the PRF fund to study another novel bio-inspired cooling technology based on tough hydrogels. We used highly stretchable and tough double network hydrogels (DN-Gels) (Fig. 5(a) as durable and resuable ‘sweating skins’ for building cooling. The DN-Gels demonstrate outstanding cooling performance, reducing the top roof surface temperature of a wood house model by 25-30 °C for up to 7 hours with a single water hydration charging (Fig. 5(b)). More importantly, compared with single network hydrogels (SN-Gels) studied previously for cooling applications, the DN-Gels exhibit extraordinary toughness and cyclability due to their interpenetrated ionically and covalently cross-linked networks, as demonstrated by constant building cooling performance for over multiple cycles (Fig. 5(c)). Our results suggest that tough DN-Gel coating based bio-inspired sweat cooling represents a promising technology for energy-efficient cooling for buildings as well as other devices and systems. This result is published in Applied Energy (2016).

Fig 5. (a) Chemical fomula of the DN-Gel. (b) Comparison of cooling effectiveness of the DN-Gel and SN-Gel. (c) Retained cooling performance after multiple cycles.

Reference:

[1] Lu, et al., Langmuir, 2015. 31: 9817.