Reports: DNI1054717-DNI10: Electrohydrodynamically Assisted Dimensional Transition of Crumpled Graphene Balls at Interfaces: Toward Selective Removal of Aromatic and Organosulfur Containments

Vincent Tung, PhD, University of california, Merced

Introduction:

The overarching goal of first stage of the proposed PRF project is exploring electrohydrodynamic means for scalable synthesis of crumpled graphene (CG) and their assembly into hierarchically structured monoliths for the removal of organosulfur contaminant. CGs are the newest addition to the graphitic family, and have already stimulated immense interests. Specifically, 3D particle-like membranes represent a unique type of nano-building block in that they possess distinctly different assembling behaviors from parent graphene by virtue of the diminishing intermolecular forces that have been known to scale with the geometries between two interacting bodies.

Results:

To synthesize CGs, we are particularly interested in chemically derived graphene (a.k.a reduced graphene oxide, rGO). rGO can be well dispersed in water without the need for foreign stabilizers by controlling its surface chemistry. For instance, the pH dependent ionizable edges of rGO enable the tuning of surface charge density. Under high pH values, deprotonation results in the negatively charged edges that render rGO sheets to repel from each other, thus preserving the single layer conformation in colloidal dispersions. Previous studies on the deformation of rGO sheets also suggest that the atomically thin yet mechanically strong materials can deform into various shapes through capillary compression due to the reduced flexural rigidity. Therefore, rGO is indeed a stimulus-responsive, soft active material with electrostatically ionizable edges and a mechanically deformable basal plane. We thus surmise that if external stimuli in the form of electrostatic and capillarity-induced-mechanical cues can be concurrently introduced, 3D CG monoliths can be rationally constructed.

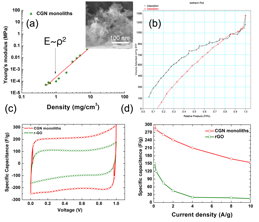

In light of the unique stimulus-responsive nature, we explored electrohydrodynamic (EHD) process as the assembling route. Conventional EHD process is nothing but a routine tool to atomize liquid medium for high throughput production of thin film specimens. However, from a colloidal chemistry perspective, electrostatically charged droplets can be viewed as nano-reactors that concurrently introduce electrostatic, and capillarity-induced-mechanical forces (Figure 1). Under a high electric field (0.575 kV/cm), The charged nano-reactor first and foremost provides electrostatic environment to propel negatively charged rGO sheets from agglomerations while the capillary forces introduce networks of ridges, ripples, folds, and vertices on the basal plane to maximize the overall contacting area, e.g., pi-pi interactions to suppress the surface tension, thus initiating the deformation process as shown in Figure 1. The resulting CGs comprise of mostly single sheets, which represents largely preserved material properties, especially those pertinent to energy applications (Figure 2). Indeed, preliminary results suggest that CGs exhibit a combination of high surface area (~1,500 m2/g), good electrical conductance (2.13x104 S/m), preserved capacity (288 F/g) when measured in a bulk form. In particular, these CGs display a unique combination of super-elasticity and high-energy loss coefficient (~80% at first cycle and ~59% after 4 cycles) upon iterative mechanical indentations.

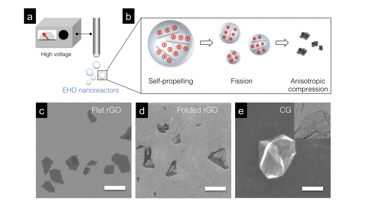

Figure 1. (a) Schematic drawing illustrates the setup of EHD process of synthesizing CG. (b) Self-dispersing droplets can be viewed as charged, nano-colloidal systems that undergo stages of (i) electrostatically induced self-propelling, (ii) fission and, (iii) anisotropic compression, ultimately leading to the formation of CG. HRSEM images of samples taken along the trajectory of deposition demonstrate a progressive transition from (c) flat, and (d) folded rGOs to (e) CG. HRTEM (inset) image reveals that CG is made of thin graphitic walls. Scale bars are 1 µm for (c), and (d), 50 nm for (e), respectively.

Figure 2. Preliminary data of (a) Young's modulus and density of CG monoliths (Inset shows HRSEM), (b) surface area, (c) specific capacitance, and (d) as a function of various current density collectively show the preserved properties of 3D CG monoliths.

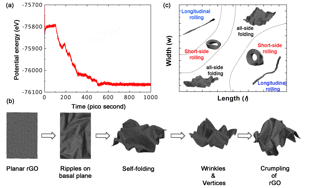

We also performed MD simulations using LAMMPS

software. MD simulations of CNTs in the presence of water are now very common. The majority of

such studies have been focused on the dynamics of water moving through a CNT.

Although the focus of our work is different, we will use previous studies to

guide and facilitate the model development (e.g. choosing interatomic

potentials, and creating initial configurations). In another study, it was

shown that water nano-droplets could activate and guide the folding of planar

graphene nanostructures. The initial

geometry of rGO configurations will be optimized using the conjugate gradient

method, and the folding simulations will be conducted with a time step of 1 fs. The crumpling process of the relatively hydrophobic

(lower surface energy) rGO sheets can be deemed as a process to minimize the

mechanical instability in colloidal dispersions. In particular, the presence of

water is expected to change the folding dynamics of CGNs as rGO sheets will

first self-fold to increase the contact area of ¹-¹ interactions which scale

with van der Waals (vdW) forces, thus minimizing the overall potential energy

(E). As shown in Figure 3a and 3b, indeed, preliminary result from MD simulation

suggests that rGO sheets will first bend and then crease to develop ridges,

thus minimizing the overall potential energy. Alternatively, from an energetic

point of view, the crumpling dynamics in this case can be briefly expressed as

the competition between vdW energy (EvdW) and elastic

bending energy (Ebend)

as following: EbendLEbendW=0.34w+2¹R+1.3520.34l+2¹R+1.352![]() , where w is

the width, and l is the length of

rGO. R is radius of the substrates

and will not be used in calculation since rGOs are freestanding. It becomes

apparent that when w<l, the ratio of EbendL

, where w is

the width, and l is the length of

rGO. R is radius of the substrates

and will not be used in calculation since rGOs are freestanding. It becomes

apparent that when w<l, the ratio of EbendL![]() /EbendW

/EbendW![]() is less

than unity, suggesting that rGO will be energetically prone to bending along

the L direction (tubular structures). With decreasing aspect ratios (w>l),

the energy ratio dramatically reduces, leading to the formation of short side

rolling and all side folding as shown in the schematic diagram of folding as a

function of length and width (Figure 3c). In the former case, EvdW

scales with the contacting area while Ebend predominately hinges on the aspect ratios.

is less

than unity, suggesting that rGO will be energetically prone to bending along

the L direction (tubular structures). With decreasing aspect ratios (w>l),

the energy ratio dramatically reduces, leading to the formation of short side

rolling and all side folding as shown in the schematic diagram of folding as a

function of length and width (Figure 3c). In the former case, EvdW

scales with the contacting area while Ebend predominately hinges on the aspect ratios.

Figure 3. (a) MD simulation reveals the change of potential energy during the crumpling process of rGO. (b) Snapshots taken from MD simulation illustrate the stages of crumpling process of rGO. (c) Schematic diagram of crumpling scenarios as a function of aspect ratios establishes a predictive shape-engineering principle for CGs.