Reports: ND752997-ND7: Oil Water Separations from Zone Annealed Block Copolymer Films

Alamgir Karim, PhD, University of Akron

Impact on research of PI: This grant has had a strong impact as a new research direction for the PI. Several new research directions in relation to membranes, and block copolymer as well as nanofilled polymer films processing for membrane applications were initiated in the PI's group as a result of the funding. This resulted in graduation of 2 Masters thesis 1 PhD student as well as the involvement of several graduate students currently working on different aspects of the work despite the ending of the ACS-PRF funding this year. While several publications have resulted from the research work initiated, one of them is highlighted on orientation of high molecular weight block copolymer thin films suitable for membrane separations applications.

Summary of Research: We demonstrate that an increase of the molecular mass (chain length N) of a cylinder-forming PS-PMMA block copolymer (BCP), and thus the Flory-Huggins interaction strength χN, allows us to form well-organized surface patterns having the technologically interesting perpendicular cylinder BCP orientation with respect to the substrate. Tuning the polymer mass also allows for a precise control of the in-plane BCP cylinder pattern wavelength λ and gives rise to a local height variation of the BCP film in which the average film roughness varies in direct proportion to λ. At a fixed ordering temperature (T=182oC), we observe an orientation transition with increasing BCP molecular mass (Mw > 77.5 kg/mol) from a parallel to a perpendicular orientation. Based on the findings of the present work, and accumulated results from our former studies of BCP ordering, we propose as a general principle that increasing the BCP segregation strength by either lowering temperature, increasing the BCP mass or the addition of molecules with a selective affinity for one of the blocks, enhances the extent of vertical ordering in BCP thin films. We suggest that this effect arises because the segregation strength χN controls the rigidity of self-assembled BCP structures.

Preparation of BCP Thin Films: A series of PS-b-PMMA samples with different molar masses were obtained from various sources and used as received (Table 1). dPS-b-PMMA BCPs with the total relative molecular mass of 77.5 kg/mol and 367.2 kg/mol were synthesize by Oak Ridge National Laboratory. PS-b-PMMA films were prepared via flow coating from the block copolymer solution in toluene onto the plasma-treated Si wafer. The procedure for generating a BCP film via flow coating is outlined as follows. A knife blade mounted on a metal holder was placed above the stage. The substrate is fixed to the translation stage beneath the blade. A fixed volume of polymer solution (50 µL for a 25-mm-wide blade) is syringed along the leading edge of the knife blade, where polymer solution is held in place by capillary forces. The liquid film then dries to a solid film. The substrates used in this study are commercially-available atomically-flat Si wafers. The plasma-treated substrates are somewhat hydrophilic, which induces a preferential wetting behavior for the PMMA phase of the block copolymer.

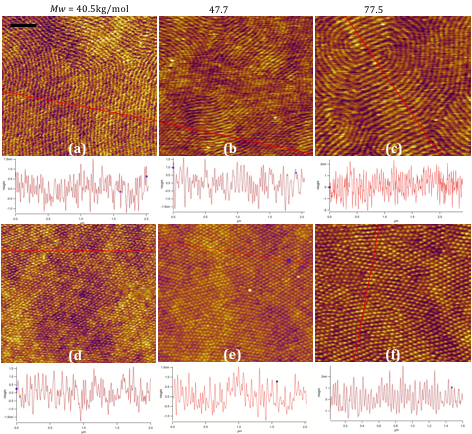

Results and Discussion: Representative AFM height images of PS-b-PMMA block copolymers with different molecular masses are shown in Figure 1. Evidently, the surface morphology of BCP thin films with molecular masses, Mw = (40.5 kg/mol, 47.7 kg/mol and 77.5 kg/mol), can be controlled by adjusting the film thickness and thermal history. A parallel cylinder BCP microphase orientation, which is natural given the wetting characteristics of the solid substrate for PMMA, is obtained by subjecting the flow-coated BCP films to annealing at relatively high temperature. In Figures 1a-1c, we observe the formation of cylinders that are oriented parallel to the substrate by annealed the BCP films at 182oC for 8h (Figures1a and 1b) and first annealed at 164 °C for 15 h and then annealing at 200 °C for 15 h (Figure1c). We then let an identical set of flow-coated BCP films order by annealing them at low temperature, 164oC (Figures 1d-1f). We also observe the formation of cylinders that are oriented perpendicular to the substrate in 77.5 kg/mol BCP thin film after annealing at 182 °C for 8 h (data not shown). Clearly, for all molecular weights in the relatively low molecular weight range, perpendicular orientation cylindrical morphology is obtained. Furthermore, this perpendicular cylinder morphology remains stable and no significant morphology evolution is observed in our thin films on reasonable annealing timescales (several days).

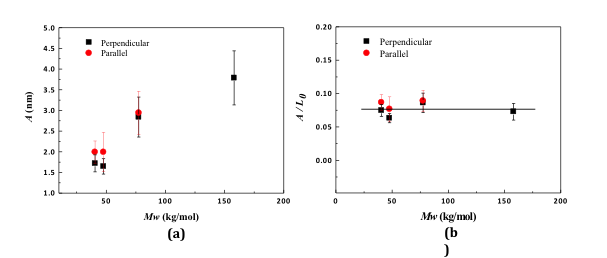

To quantify the influence of molecular mass on the height variations of BCP films, the amplitude of the BCP film thickness undulations was normalized by the cylinder period distance. Figure 2b shows this dimensionless ratio is an invariant in molecular mass in the wide range investigated (40.5 to 367.2) kg/mol. We thus have a general method for engineering the well-controlled nanoscale fluctuations, both in height and in-plane pattern wavelength, through the control of the BCP molecular mass, which should be a useful tool in designing BCP films with targeted structure.

Figure 1. AFM height images for PS-PMMA BCPs with Mw = 40.5 kg/mol (left column), and 47.7 kg/mol(center column) and 77.5 kg/mol (right column). Representative images of BCP film with hf = 124 nm annealed at 182 ° C for 8 h (a), hf = 168 nm annealed at 182 °C for 8 h (b), hf =141nm first annealed at 164 °C for 15 h and then annealing at 200 °C for 15 h(c), hf = 124 nm annealed at 164 °C for 8 h (d) hf =130 nm annealed at 164&#deg; C for 15h(e) and hf = 94 nm annealed at 164 °C for 15 h (f). The scale bar is 200 nm, and applies to all images. One dimensional height traces are provided below each AFM height image with corresponding position on the image indicated by a red line.

Figure 2. (a) Amplitude (A) of film height undulations at the surface of BCP films having perpendicular and parallel cylinder orientations. (b) The normalized amplitude by the cylinder period distance.