Reports: ND754028-ND7: Nanosphere and Nanorod Diffusion in Polymer Melts

Russell J. Composto, University of Pennsylvania

1) Diffusion of Polymer-Grafted Nanospheres in Melts

In the present study, we investigate poly(methyl methacrylate)-grafted NP diffusion in

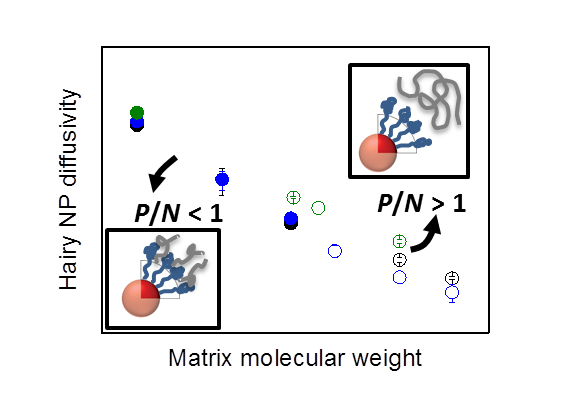

poly(methyl methacrylate), or PMMA, matrices by varying brush grafting density, brush molecular weight, and matrix molecular weight. PMMA-grafted NPs with Fe3O4 core (d = 5 nm) are prepared as follows: IO21L (N = 21 kg/mol, σ = 0.17 chains/nm2), IO21M (N = 21 kg/mol, σ = 0.33 chains/nm2) and IO16H (N = 16 kg/mol, σ = 0.55 chains/nm2). The diffusion coefficients of PMMA-grafted NPs diffuse into PMMA matrices (P = 4 to 50 kg/mol) were measured and were found to be independent of annealing time, suggesting that NPs do not form aggregates when diffusing in the matrix, consistent with TEM analysis. Diffusion coefficients decrease monotonically with increasing matrix molecular weight for the three NPs as shown in Figure 1. When the brushes are wet by the matrix chain, i.e., P/N < 1, IO21L and IO21M have similar diffusion coefficients due to the dragging of matrix chains as brushes and matrix chains interpenetrate significantly. On the other hand, IO16H has the largest diffusion coefficients due to weaker dragging of matrix chains because its high grafting density results in less brush-matrix interpenetration. When the brushes are dry, i.e., P/N > 1, IO21L (black circles) has faster diffusion than IO21M (blue circles) due to the lower grafting density resulting in the smaller effective diameter. Furthermore, IO16H (green circles) exhibits the fastest diffusion among the three because of a combined effect of its high grafting density and short brush, resulting in a smaller effective diameter and less dragging of PMMA as shown in Figure 1. Brush and matrix density profiles were calculated using self-consistent field theory (SCFT) and the result shows that grafting density has the strongest effect on the profiles, which further supports the effect of brush structure on NP diffusion that can be attributed to dragging of matrix chains and the effective diameter in the dry brush regime. This study underlines the importance of the effect of polymer brush structure on NP center of mass diffusion in polymer melts.

Figure 1. Slowing down of nanoparticle diffusion as the matrix viscosity increases. Also, the effect of brush length and grafting density is shown for the nanoparticles with low (black circles), medium (blue) and high (green) grafting densities.

2) Diffusion of Quantum Dot Nanoparticles in Swollen Polymer Gels

Advances in the areas of drug delivery, filtration, and other applications involving swollen polymer systems would benefit from a quantitative understanding of how structural parameters of polymer networks effect nanoparticle (NP) diffusion. Our current study aims to determine this relationships for chemically cross-linked systems. Our work will compare a wide range of mesh sizes and confinement ratios, as well as heterogeneous and homogenous gel systems. This will allow us to study whether NP hopping is an important mechanism for these systems and how heterogeneity impacts diffusion behavior. The homogeneous gel will serve as a model system for determining scaling relationships of NP diffusion in highly cross-linked systems. These studies aim to quantify diffusion in these networked systems and relate the trend in diffusion coefficient to confinement ratios to test theoretical predictions.

The two gel systems being used in this study are tetra poly(ethylene glycol) (Tetra-PEG) networks and polyacrylamide gels (PAGs). Tetra-PEG stars were functionalized with specific end chemistry resulting in controlled cross-linking and a homogeneous mesh on the order of a few nanometers in size. The free radical polymerization of PAGs resulted in a heterogeneous mesh. Quantum dot NPs (CdSe/ZnS), functionalized with PEG brushes, were used in this study. Single particle tracking was used to determine NP trajectories, mean squared displacements, and diffusion coefficients. The effect of confinement ratio on the diffusion mechanism of the NPs was observed in the collected ensemble and individual trajectories for each system. When the mesh size is larger than the NP, the NPs move diffusively. When the mesh size becomes smaller than the NP size, the particles begin to exhibit intermittent localization followed by jumps. The behavior of localized diffusion followed by larger jumps in displacement indicates that the confinement of the mesh creates a barrier that must be overcome to end localization. When the particles are much larger than the mesh size (~8 times), they become localized, leaving their mesh “cage” only on rare occasions. This study highlights the impact of the structural environment on NP diffusion in confined polymer systems.