Reports: ND1054550-ND10: Electrode Stability in High Temperature Sensors for Petroleum Applications

Jacob L. Jones, North Carolina State University

A report on dewetting morphology evolution of gold thin film on indium tin oxide

PI: Professor Jacob L. Jones

PhD Student: Ms. Hanhan Zhou

Thin metal films deposited on insulator substrates are thermodynamically unstable. When such thin films are heated to temperatures below the film’s melting temperature, agglomeration driven by minimization of surface energy occurs. This agglomeration behavior is called dewetting. The dewetting of thin films in solid-state is a serious issue for petroleum industrial applications. Under the presence of dewetting, the thin film can degrade the performance of the sensors by breaking the connectivity of the film. In this specific project, we investigated Au thin film deposited on indium tin oxide (ITO) substrate system, with a goal to develop fundamental knowledge of dewetting behavior from both thermodynamics and kinetics view by using both ex situ and in situ techniques. This research will enable the new design of stable microelectronic devices applied in petroleum industry.

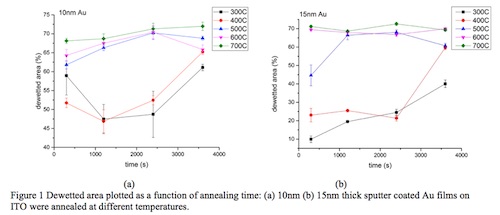

During the first year of the project, we have successfully explored the annealing conditions to induce dewetting to occur and also studied the dependence of dewetting morphology on film thickness. 10 nm and 15 nm thick Au films were sputter deposited on ITO respectively. All samples were annealed at for 5 min, 20 min, 40 min and 60 min respectively at a temperature range from 300°C to 700°C in nitrogen environment. To explore how film thickness and annealing conditions influence dewetting behavior, we took scanning electronic microscope (SEM) images at five different positions of each sample. The dewetted area was calculated using image analysis software. Figure 1 shows the dewetted area of samples with different thickness as a function of annealing stime. In the same annealing conditions, the thinner samples dewetted more compared with that of the thicker samples. Moreover, when the film thickness was fixed, as the annealing time or annealing temperature increased, dewetted area also increased. Also, from the dewetted area measurement, we observed an interesting phenomenon. For a sample with a fixed thickness, the dewetted area increased sharply from 400°C to 500°C. However, once the annealing temperature increased above 500°C, dewetting reached a saturation point where dewetted area increased slightly.

After determining the annealing conditions for dewetting to occur, we next started planning in situ SEM experiments to observe real time changes of Au layer during dewetting process and to develop a kinetics model of dewetting. The working principle of the in situ experiment involves a heating stage made of a ceramic membrane that sits on a silicon substrate to conduct heat. The sample is supported on the center of thermal E-chip with an area of 500µm x 500µm. Currently, this experiment is in development.

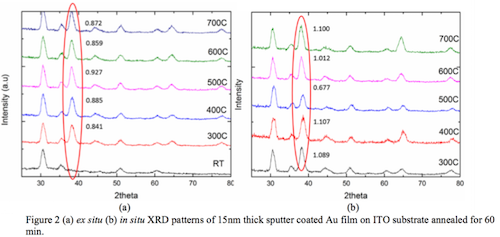

During dewetting, it is expected that grains reorient to minimize surface energy. The change of grain orientation can be observed in the diffraction pattern as a change in the peak intensity. Therefore, to explore the influence of dewetting on the texture of the Au thin film, we firstly conducted ex situ grazing incidence X-ray diffraction (XRD) technique on the dewetted samples annealed for 60 min at several temperatures. Figure 2 (a) shows the corresponding XRD patterns. As we predicted, dewetting induced a preferred texture of the Au thin film, with a (111) orientation. To further characterize the change in preferred orientation during dewetting, we executed in situ grazing incidence XRD on a sample coated with 15 nm thick Au. The sample was heated up from room temperature to 700°C with an increment of 100°C and was hold for 60min at every intermediate temperature. As seen from figure 2 (b), the maximum change of (111) peak intensity occurred as the sample was heated from 400°C to 500°C.

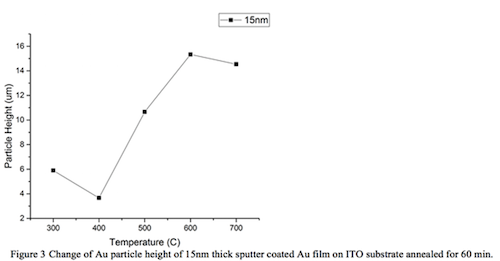

To characterize the change of height of Au particles during dewetting, we next performed atomic force microscope (AFM) technique on the dewetted samples annealed for 60 min at several temperatures. The result was plotted as a function of annealing temperature in figure 3. As we expected, the particle height increased as the annealing temperature increased. However, an interesting phenomenon was also observed in this data: the particle height increased sharply from 400°C to 500°C.

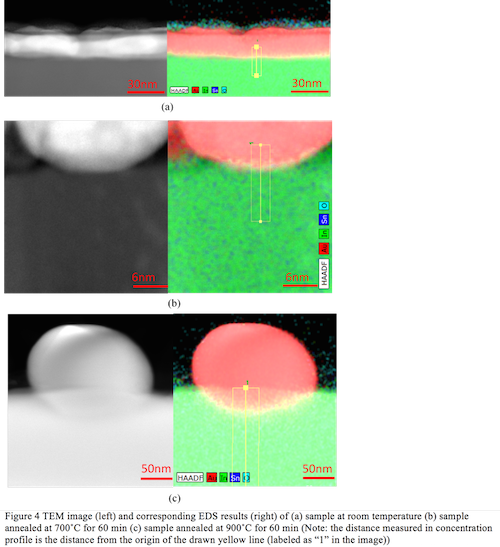

From this observation and the measurements of dewetted area as a function of annealing time, we were able to hypothesize that inter-diffusion between Au layer and ITO facilitated dewetting, a process that mainly occurs via surface diffusion. Generally, diffusion phenomenon is more perceivable at a higher temperature. To test the hypothesis, we performed an energy dispersive microscopy (EDS) using transmission electron microscopy (TEM) to study the role of inter-diffusion in dewetting behavior. EDS was applied at a sample of room temperature and samples annealed at 60 mins for 700°C and 900°C respectively. This EDS results can be seen in Figure 4.

The concentration gradient at the interface of film and substrate was determined from the obtained concentration profile. To overcome the inconsistent tilted measurement angles between samples, an in situ TEM experiment has also been initiated.

This research will impact the existing technologies including wireless sensors, microelectronics and in situ monitoring devices in petroleum industry. Moreover, the produced fundamental knowledge will enable the design of devices with more stable interfaces that can be applied under extreme environments.

The project has positively influenced the PI and student’s career, particularly through the development of in situ characterization techniques for studying temperature-dependent phenomena. Through the project, the PI and student have developed new characterization techniques within the shared user facility, the Analytical Instrumentation Facility. The results of the project have been communicated to other investigators in order to demonstrate these capabilities. I.e., while the results of the materials studied are of immediate interest to materials scientists, the new in situ characterization techniques will also have a significant impact in other areas of science and technology.