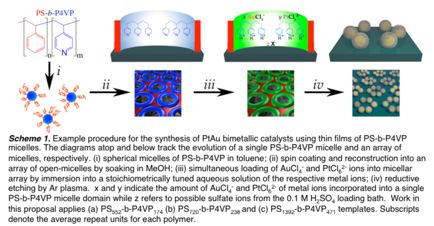

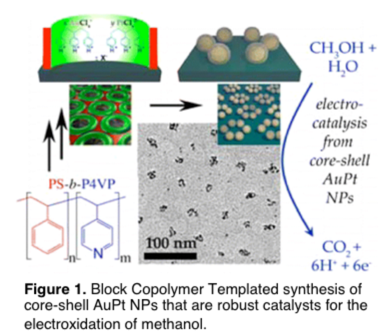

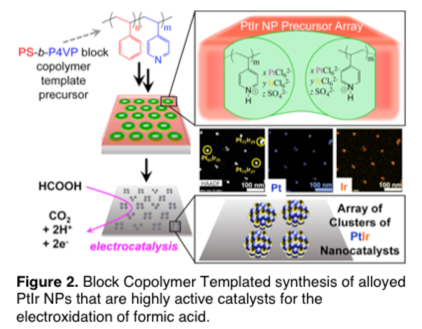

Reports: UR1054780-UR10: Understanding and Utilizing Block Copolymer Templates for the Preparation of Bimetallic Catalysts for Fuel Cell Applications

David Rider, PhD, BS, Western Washington University

David Rider, PhD, BS, Western Washington University

Reports in the ACS PRF Annual Report are published as submitted by the Principal Investigator.

Copyright © American Chemical Society