Reports: DNI953099-DNI9: The Effects of Micro-Structure on the Rheology of Heavy Crude Oil

Iman Borazjani, PhD, State University of New York at Buffalo

Introduction and Objectives

Increasing energy costs have attracted oil companies to tap into heavy crude oil reserves. Heavy crude oil is a colloidal suspension of aggregates of many compounds (resins and asphaltenes), which give rise to very unusual rheological properties such as non-Newtonian behavior and very high viscosity. Such high viscosity leads to difficulties in the production/transportation of heavy crude oil. To optimize processes to lower viscosity and improve flow properties of heavy crude oil, a better understanding of the relationship between micro-structure and macro rheological behavior is required. Here we propose to study the effects of micro-structure (size, shape, polydispersity, concentration, etc.) on the rheology of heavy crude oil using state-of-the-art numerical simulations without the simplifying assumptions of previous theoretical models. Methods

We use our well-validated, sharp-interface immersed boundary method to simulate colloidal suspensions of asphaltene with their experimentally observed micro-structure. We have incorporated the methods for calculating the particle stresses that affect the bulk stress of the suspension, from which the effective viscosity of the suspension is determined. Moreover, we separately calculate different terms affecting the bulk stress, to identify the relative importance of different mechanisms of stress generation in the suspension.

Results

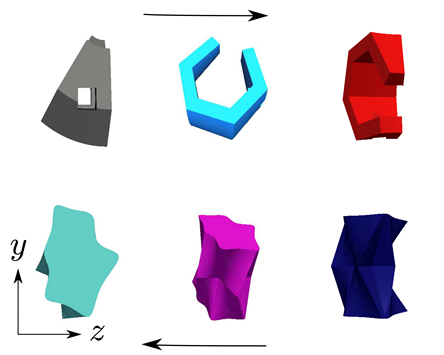

Figure 1 Schematic of different cases based on initial orientation. Case1, case2, and case3 are constructed from a slender curved particle and case4, case5, and case6 are made from a solid particle without any holes. The arrows show the direction shear flow around the particles.

We picked two different particle shapes: one solid, and the other one, curved an slander shape with holes with approximately equal length and aspect ratio. For each particle we initially oriented the particle in three different angles to make 6 test cases.

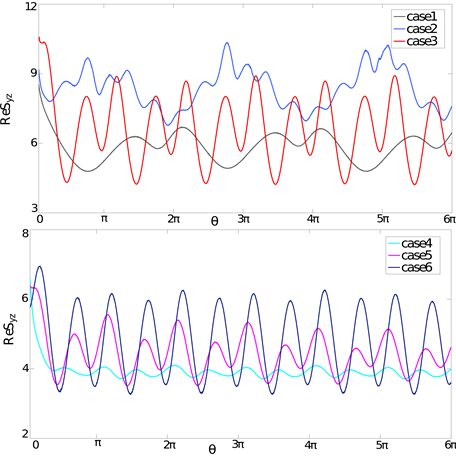

Figure 2 Particle's instantaneous stresslet as a function of orientation for two complex-shaped particles with different initial orientations in a suspension with volume fraction ϕ= 0.058 and Re= 1.0.

We found that the stresslet of particles (main component of total particle stress) is a complex function of initial orientation and particle shape and can be considerably higher or lower when particles rotate in different orbits. One important point about the role of shape on stresslet of a complex-shaped particle is that slenderness of a particle can significantly (more than two time for particles having close aspect ratios in our simulations) increase the cycle-averaged stresslet. The results of this research have been presented at the APS conference (APS DFD 2014). Furthermore, the work has resulted in a journal paper, and another journal paper is under preparation.

Future work

For the next year we will focus on more complex geometries based on the experimentally observed micro-structure. We will start incorporating collision models to simulate many particles to investigate the effects of polydispersity on the mechanisms of stress generation in a suspension.