Reports: DNI752345-DNI7: Elucidating the Structure and Properties of Model Bottlebrush Polymers

Rafael Verduzco, PhD, Rice University

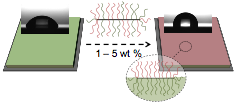

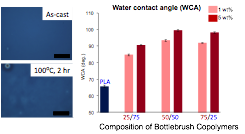

To determine if bottlebrush

copolymers spontaneously segregate to the top of thin film blends, we first

measured the water contact angle (WCA) for bulk PLA films and found a value of

65.7 ± 1°.