Reports: ND554179-ND5: Fundamental Properties of Two-Dimensional Zeolites

Uwe Burghaus, North Dakota State University

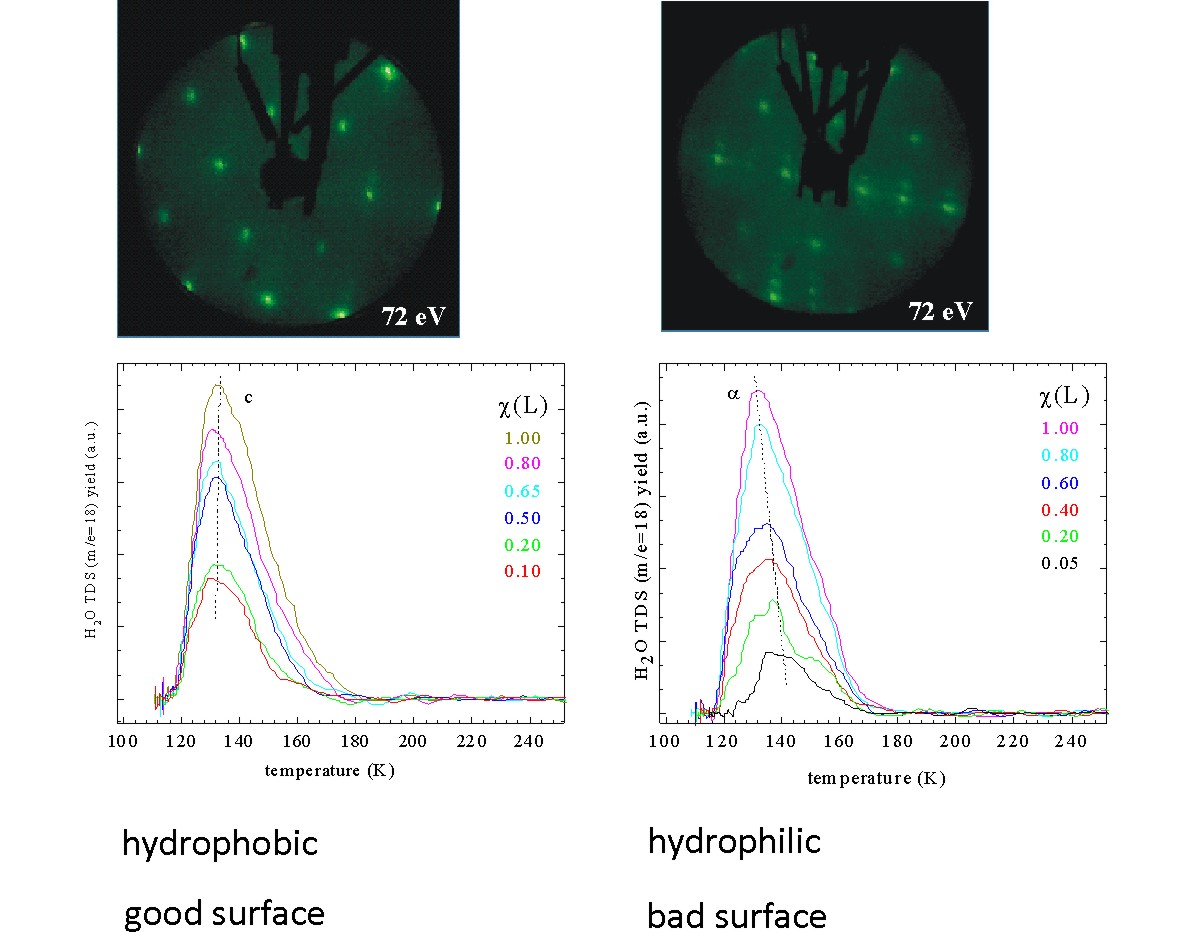

1) Synthesize/fabricate 2D zeolite-like films (“Al-doped silica films”), which

requires first to synthesize 2D crystalline silica; 2) Use thiophene

to probe catalytic activity by means of surface chemistry techniques; 3)

Deposit Mo on/in the porous support targeting hydrodesulphurization–related

(HDS) surface chemistry as petroleum-related research.