Reports: ND753386-ND7: Buckling-Induced Morphological Transformations in Block Copolymers

Sachin Velankar, University of Pittsburgh

When a thin stiff film bonded to a softer substrate is compressed, it buckles and develops numerous wrinkles. Such wrinkled surfaces have numerous potential applications as smart surfaces with tunable adhesion, friction or wettability, flexible electronics, or mechanical tenability. This project seeks to transplant these phenomena of thin film buckling to develop buckled materials which show unusual mechanical properties.

In the first year of the project, we had initiated research on styrene-butadiene triblock copolymer (SBS) copolymer with a morphology consisting of polystyrene (PS) cylinders in a polybutadiene matrix. We had developed protocols to align the cylinders, and then crosslink the films. In the second year, we have initiated the core of the studies, viz. to subject such crosslinked films to a specific thermomechanical history intended to develop internal stress in the samples, specifically, to subject the PS cylinders to compressive stress. Initial crude attempts to apply the thermomechanical histories were not very successful. Since April 2015, our research has been greatly facilitated by the acquisition of a new shear rheometer along with an accessory for extensional rheometry. Thus, the desired thermomechanical history can be applied exactly with precise temperature control and with measurement of the strains applied and during recovery.

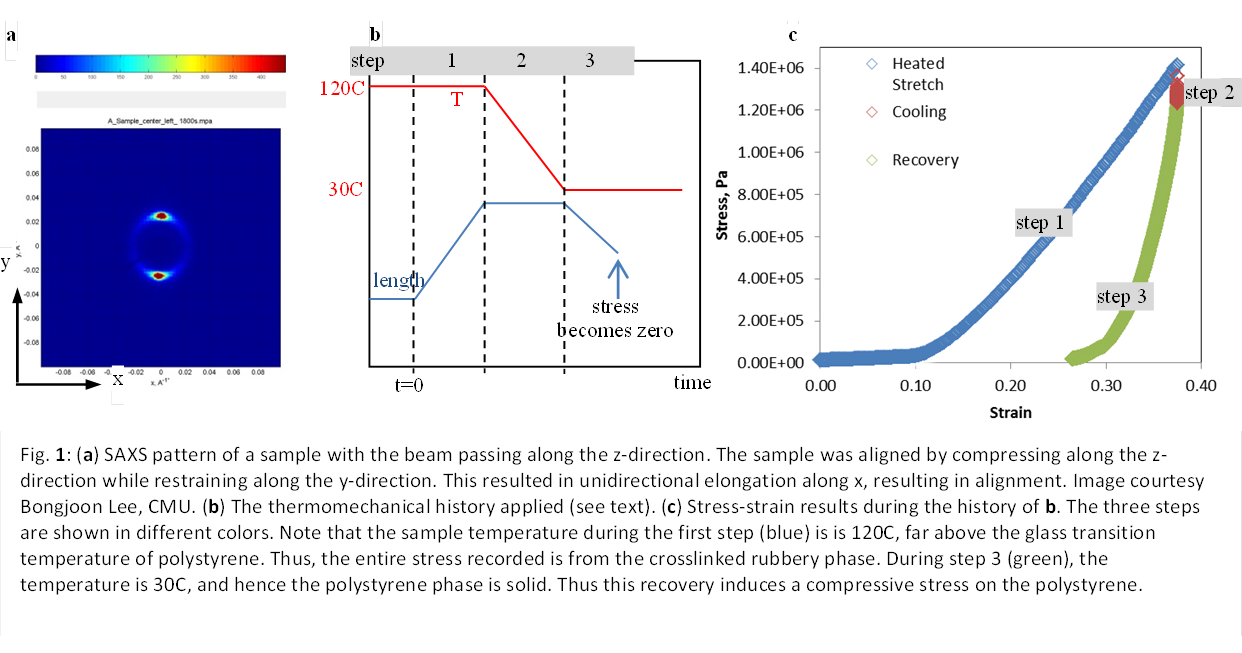

Fig. 1 illustrates our results. A block copolymer (Dexco Vector 8508A, with 29% styrene) with a cylindrical morphology was aligned uniaxially by planar compression under molten conditions, followed by immersion into mixture of crosslinker and photoinitator, and then crosslinking. Fig. 1a shows the small-angle x-ray scattering pattern, and excellent alignment is evident. Subsequently, the sample was subjected to thermomechanical history of Fig. 1b, resulting in the stress-strain data of Fig. 1c. The goal of these steps is to create a structure with an internal stress: specifically, at the end of step 2, one expects the polystyrene cylinders to be glassy and stress-free, whereas the crosslinked network to be rubbery and under tensile stress. During step 3, the rubbery phase seeks to relax its stress, thus inducing a compressive stress on the PS cylinders. We hypothesize that this compressive stress induces buckling of the cylinders. The measured recovery curves offer some support for this hypothesis (see footnote at the end), but direct confirmation requires small-angle x-ray scattering experiments. These experiments are substantially more challenging than Fig. 1a since – if buckling does happen – only subtle changes in the scattering pattern are expected. Thus high x-ray intensity and excellent angular resolution are both necessary. We have now written a grant proposal to the Advanced Photon Source at Brookhaven National Laboratory to request beam time for synchrotron experiments. This proposal is in collaboration with Prof. Wesley Burghardt from Northwestern University who has previous expertise in SAXS studies of block copolymers, and has the specialized equipment needed to impose extensional stress on the samples at the synchrotron facility.

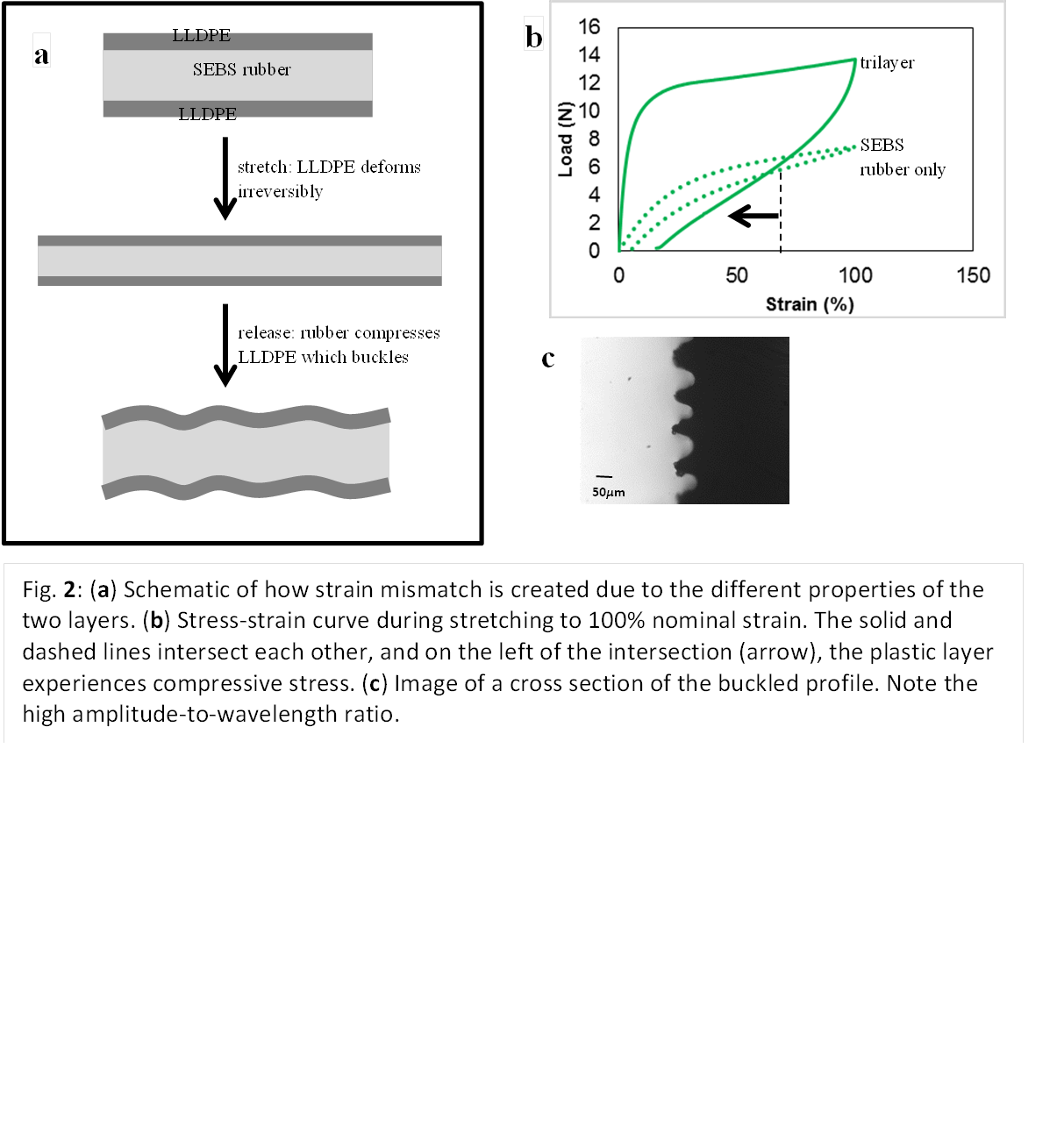

In parallel with the investigation of block copolymers, we have also conducted studies of buckling in layered systems that have been created not by self-assembly, but by “forced” assembly. Experiments are conducted by bonding thin layers of linear low-density polyethylene (LLDPE) to both surfaces of thick sheets of styrene-ethylene/butylene-styrene rubber (SEBS), and then stretching the trilayer sandwich. Since LLDPE shows a large plastic deformation whereas the rubber shows large elastic deformation, at the end of the stretching process, the situation is analogous to that discussed above. Releasing the samples induces buckling of the thin layers.

We have conducted a detailed study of this phenomenon. Fig. 2 is an example of the results. Fig. 2a illustrates the basic strain history applied. Unlike Fig. 1, the entire process is at room temperature since the LLDPE can undergo plastic deformation at room temperature (whereas PS cannot). Fig. 2b compares the tensile load-strain curves (note that the load is NOT normalized to give a stress) of the rubber layer alone, as well as a plastic-rubber-plastic trilayer. The difference between these curves may be regarded as the load borne by the plastic. At some stage during recovery, the two curves cross each other. Upon further recovery, the plastic layers experience compression and buckle. We have measured the dependence of wavelength and amplitude on the strain and on the geometric parameters. What is most useful is that large amplitude to wavelength ratios (~0.5) can realized. Wrinkled surfaces have numerous potential applications, but most past experiments are unable to reach aspect amplitude to wavelength ratios of 0.3. Simulations in collaboration with Prof. Spandan Maiti suggest that buckling in such plastic-elastic combinations is fundamentally different from that in elastic-elastic combinations. These results are now in a manuscript about to be submitted to Soft Matter.

In summary the results thus far show that the central concept being developed in this project, viz. using internal strain mismatch to create buckled materials, is now validated at macroscopic lengthscales. But for block copolymers with nano-scale morphologies, SAXS confirmation is needed.