Reports: ND953143-ND9: Transitions and Instabilities in Shear Banding Fluids

Susan J. Muller, PhD, University of California, Berkeley

Major goals of the project:

A broad range of industrially relevant fluids, including powders, suspensions, oil sands, and foams, exhibit shear banding: in flow, discontinuities in the velocity gradient develop, splitting the material into a high shear rate band and a low shear rate band. The processing of shear banding materials is relevant to petroleum production from weakly consolidated reservoirs where shear bands play a critical role in wellbore collapse.

Recent theoretical and experimental work suggests that both interfacial and purely elastic instabilities may occur in these systems. Inertial instabilities are also likely, and these systems thus promise incredibly rich dynamics. In addition, optimal processing of shear banding materials requires an understanding of the scaling of instabilities with these driving forces (interfacial, elastic, and inertial), how these modes of instability interact, and how the boundary conditions affect stability. Wormlike micellar solutions provide a convenient and versatile model system for studies of shear banding systems, and are being used in the present study to gain a better understanding of flow transitions and instabilities in shear banding systems.

We are using Taylor-Couette (TC) flow, that is, the flow between concentric, rotating cylinders, as the model flow for these experimental studies. Using a custom-built Taylor-Couette apparatus, which allows independent, computer-controlled rotation of the two cylinders and the establishment of programmable ramping protocols, we are working towards (a) isolating purely elastic and interfacial transitions from inertial ones through the use of outer-cylinder rotation, (b) using counter-rotation of the cylinders to introduce a nodal surface and probe the effects of no-slip versus free boundary conditions for various instability modes, and (c) using a combination of counter-rotation, solution concentration, temperature, and inner cylinder radii to systematically explore the competition between interfacial, inertial, and elastic instabilities and understand how each mode scales with geometric (curvature) and kinematic variables.

Ultimately, understanding the role of the destabilizing forces, the scaling of the instabilities with curvature, shear rate, normal stresses, etc., understanding the role of boundary conditions, and how the three modes of instability (interfacial, elastic, and inertial) interact, will improve the modeling of and impact processing of complex, shear banding materials.

Accomplishments to date:

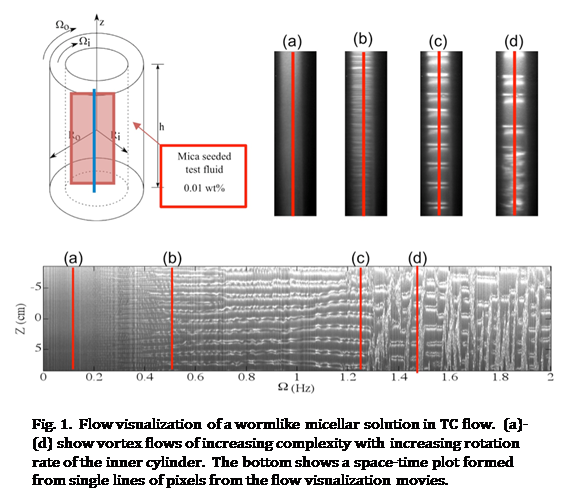

During this second reporting period, the shear banding

system CTAB/NaNO3 was studied in the Taylor-Couette cell. We

observed the bulk elastic instability in shear banding wormlike micelles and

have explored the effect of a variety of parameters on this instability. Sample

visualization results from an experiment in which the inner cylinder rotation

speed In order to better understand the time scales present in

this system, startup of steady shear experiments were performed in the TC cell

and four stages for interface formation and evolution were observed, as noted

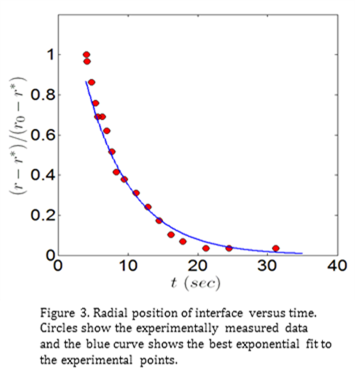

by others (Fardin and Lerouge, EPJE, 2012). For the interface travel stage in

particular, the flat, diffuse interface becomes sharp and moves slightly toward

the inner cylinder. The radial position of the interface during the interface

travel stage can be related to the stress diffusion coefficient, D, that

appears in the diffusive Johnson-Segalman model (dJS) of wormlike micellar

solutions. The dJS model has been used by Fielding and others to describe the

dynamics of this system in simulations.

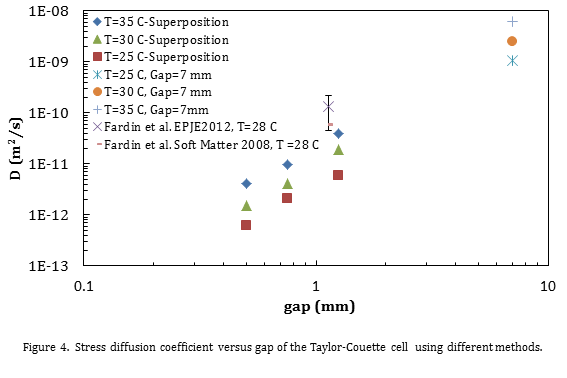

We also used superposition rheology to measure the stress diffusion

coefficient for the CTAB/NaNO3 system. In this method a small

amplitude oscillatory shear flow is combined with a steady shear flow and the

response of the system is evaluated by measuring the complex viscosity. For

Weissenberg numbers in the shear banding regime, a two fluid model is used to

predict the velocity of the interface during the travel stage and therefore,

the stress diffusion coefficient [Lettinga et al., J. Rheol, 2007]. We again

find that the stress diffusion coefficient increases with increasing

temperature in agreement with the interface visualization results. When

results from these two methods are combined, we observe that the diffusion

coefficient monotonically increases with increasing gap in the Taylor-Couette

cell (Fig. 4). This is an unexpected result, but explains some

inconsistencies in the literature for values of the stress diffusion

coefficient. The strong dependence of the stress diffusion coefficient D on

the length scale of the geometry used in the measurements has also been

demonstrated in a second system, CPCl/NaSal (data not shown). We are presently

working to understand the origin of this dependence.

In addition, we are also working towards examining the

dynamics of wormlike micellar systems as the Elasticity number, El= Wi/Re ,

approaches 1 and the case of El <1, where both inertia and elastic effects

are important.