Reports: DNI1054129-DNI10: High Performance Thermal Diode Using Polyethylene Nanofibers

Tengfei Luo, PhD, University of Notre Dame

The progress documented is on two sub-topics: (1) thermally conductive polymers with high thermal stability, and (2) thermal switch and thermal rectification using polyethylene nanofibers. Molecular dynamics simulations (MD) are used in the study of both topics. Our fundamental research results can be beneficial for many applications: for example, high thermal conductivity are desired in thermal interface material and heat spreader; tunable thermal conductivity is critical in applications such as thermal management of electronics, phononics, sensors, and energy storage and conversion. This ACS grant has enabled me to launch an important aspect of research ¨C thermal rectification. The simulation results have shown great promise and will motivate us to further work on this topic to realize polymer fiber based thermal diode with unprecedented thermal rectification factors.

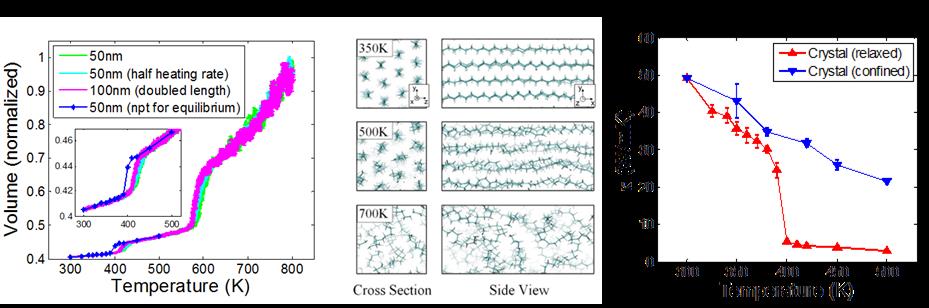

We first found that thermal conductivity in ethylene nanofiber is morphology dependent. In our MD simulations, 40 PE chains in rhombic lattice are used as the initial crystalline structure. After fully relaxation at 300K, temperature is increased from 300K to 800K, and two volume jumps at ~400K and 600K are observed (Figure 1a). During the volume jump at ~400K, chain morphology changes from all-tran crystalline structure to aligned chains with disorders (Figure 1b). Due to the disorder-assisted phonon scattering, thermal conductivity is found to drop from ~25 W/mK to ~5 W/mK at ~400K (red line, Figure 1c).

To better isolate the morphology effects, instead of allowing thermal expansion and structure relaxation, the crystal structure at 300K with a constant volume is used to calculate its thermal conductivity at different temperatures (blue line, Figure 1c). Since the volume is not expanded at higher temperatures in this set of simulations, the chain segment rotation is largely suppressed due to the confined space for each chain in the crystal. This helps keeping the along-chain lattice order and thus significantly reduces the morphology-induced phonon scattering. The lack of the abrupt drop of the thermal conductivity of the confined PE crystal confirms that the thermal conductivity collapse of the relaxed PE crystal is induced by the significant morphology change.

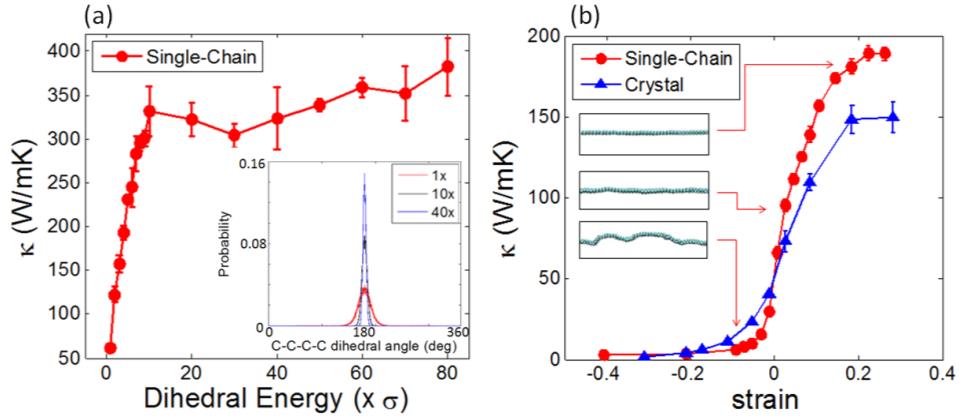

To better understand the importance of morphology, PE chains with different along-chain order are studies by either artificially tuning backbone rigidness in single chain PE or applying different strains in both single-chain and crystalline PE. Figure 2 shows that larger thermal conductivity is found in straighter chains that are simulated by creating more rigid backbone or applying larger strains. Our results show that chain morphology is critical to the thermal transport in PE structures, and PE nanofiber is not suitable for application at high temperature.

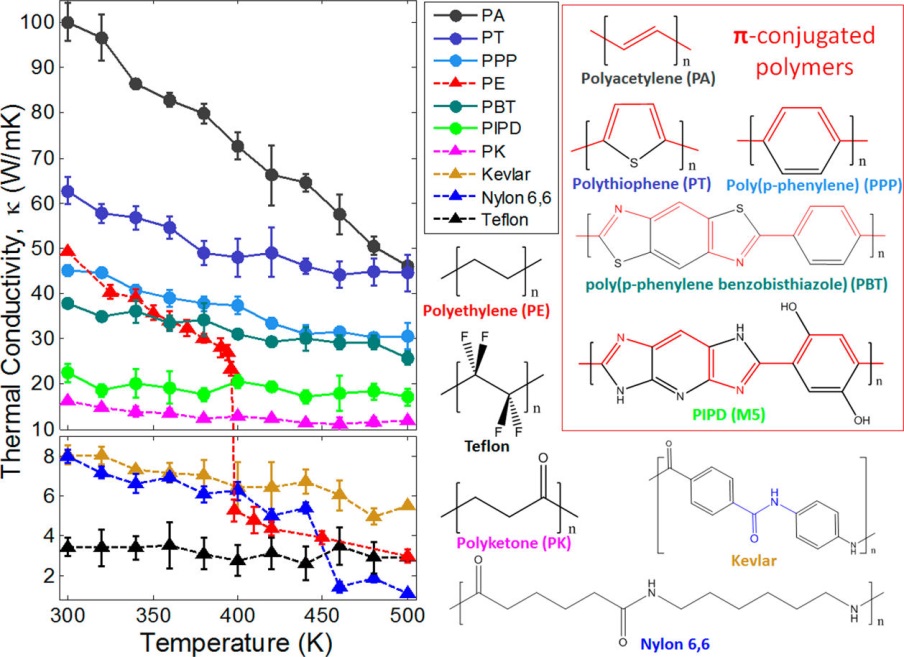

To find out thermally conductive polymer fibers that are applicable at higher temperature (above 400K), 10 different fibers are further investigated using MD simulations. Our study links molecular characteristics (backbone bond, chain rigidness, inter-chain interaction, and etc.) to macroscopic thermal properties (phase transition, and thermal conductivity), and provides a general rule of designing thermally conductive polymer nanofibers with high temperature stabilities: one should choose molecules with intrinsically ordered backbones, strong backbone bonds, and strong dihedral angles. According to this rule, ¦Ð-conjugated polymers are singled out as a category of polymers that are ideal for fabricating nanofibers with high thermal conductivities for high-temperature applications (Figure 3).

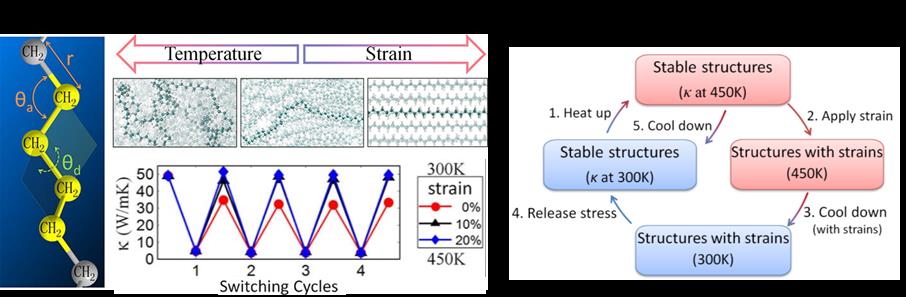

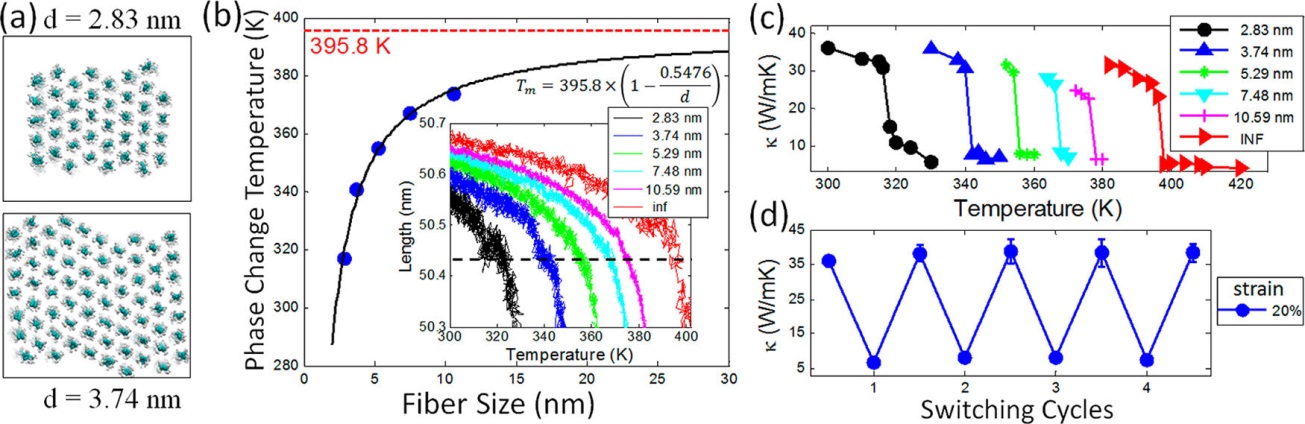

Based on the previous finding that thermal conductivity of polyethylene can be modulated by the morphology change, we demonstrate a high-contrast, reversible thermal conductivity regulation utilizing the phase transition of polyethylene nanofibers, which enables a thermal conductivity tuning factor of 12, exceeding all previously reported values (Figure 4). The thermal conductivity change roots from the segmental rotations along the polymer chains, which introduce along chain morphology disorder that significantly interrupts phonon transport along the molecular chains. This phase transition, which can be regulated by temperature, strain, or their combinations, is found to be fully reversible in the polyethylene nanofibers and can happen at a narrow temperature window (Figure 4c). The phase change temperature can be further tuned by engineering the diameters of the nanofibers, making such a thermal conductivity regulation scheme adaptable to different application needs (Figure 5). The findings can stimulate significant research interest in nanoscale heat transfer control.

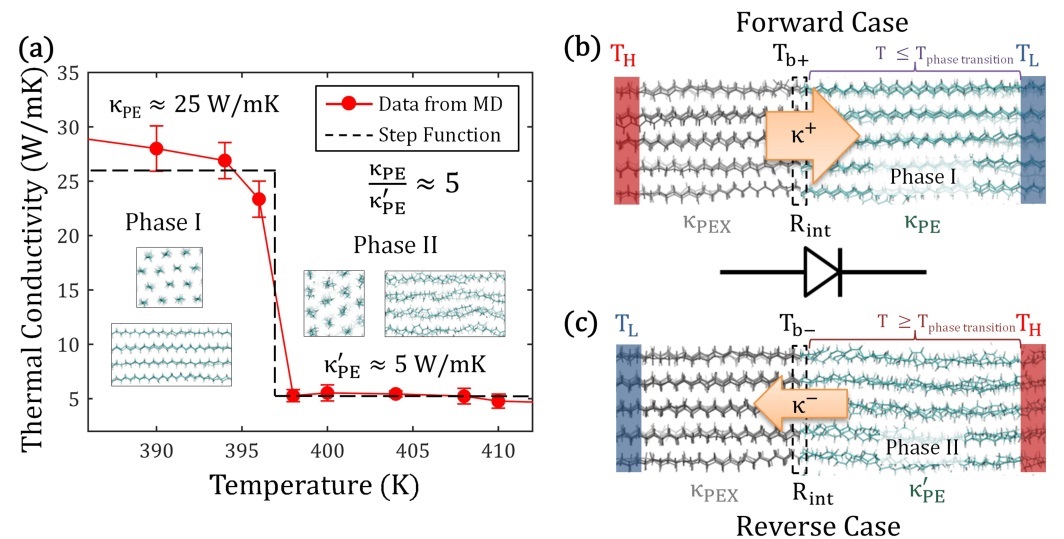

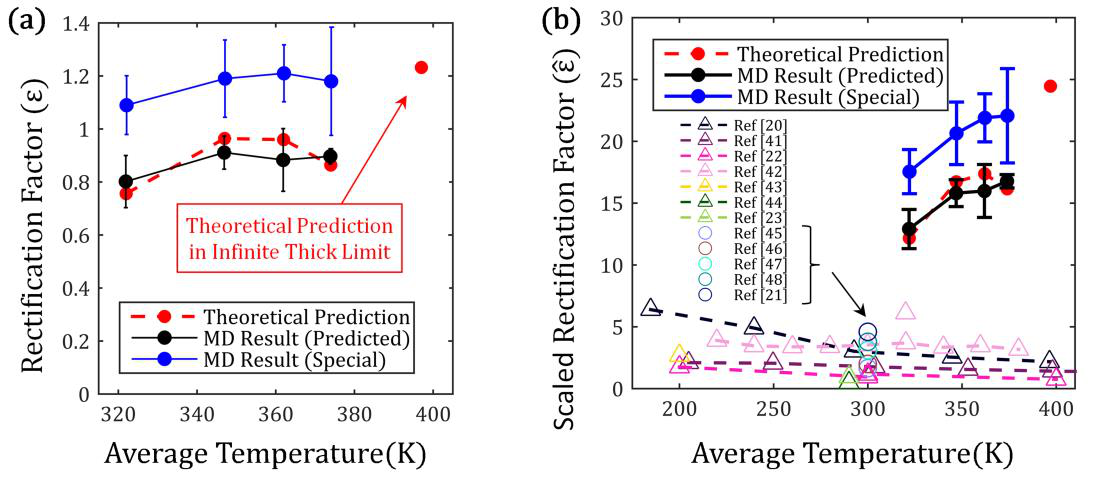

Based on the fully reversible thermal conductivity regulation using polyethylene nanofibers, we propose and study a bi-material fiber junction by connecting a crystalline polyethylene (PE) fiber to a cross-linked PE (PEX) fiber to realize very high thermal rectification factors, the highest reported value with small temperature difference over the device (Figure 6). As the temperature bias is flipped, the linear PE portion undergoes phase transition while the PEX portion does not, thus resulting in a significant change of effective thermal conductivity and large thermal rectification (Figure 6b). MD simulations confirm that the large thermal rectification factor can be achieved with only a 20 K temperature difference, which is small enough for real applications. Further MD simulations also demonstrate that the rectification can happen at a wide temperature range and is reversible (Figure 7a). Using the temperature-scale rectification factors (proposed by Dames) to evaluate the rectification efficiency, our device shows a much larger temperature-rectification factor compared to previously reported thermal diodes (Figure 7b). Although some challenges are expected to be tackled in the experimental realization of such a device, the results from this work may open up a new direction for thermal rectification research and provide important guidance to achieve practically usable thermal diodes based on inexpensive and easily processible polymer fibers.

Figure 1 Phase transition enabled thermal conductivity change.

Figure 2. Chain segmental order influenced thermal conductivity.

Figure 3. Thermal conductivity of different polymer chains.

Figure 4. Morphology controlled reversible thermal switch.

Figure 5. Nano size effect enabled switching temperature tuning.

Figure 6. (a) Sharp thermal conductivity change of PENF due to phase transition. Schematics of PE¨CPEX thermal diode junction with (b) forward and (c) reverse temperature biases.

Figure 7. (a) Thermal rectification factors for PE¨CPEX fibers with different diameters. (b) Dimensionless temperature-scaled thermal rectification factors for PE¨CPEX diodes and other nanoscale thermal diodes reported in the literature.(see DOI: 10.1002/smll.201501127 for references)