Reports: ND952789-ND9: Realizing the Selectivity of Exothermic Partial Oxidation Reactions

Anthony G. Dixon, Worcester Polytechnic Institute

1-Introduction

Multitubular fixed bed reactors are

widely used in the chemical industry, especially for partial oxidation

reactions. Due to the fast and highly exothermic nature of these reactions

strong species concentration and temperature gradients exist in the reactor,

leading to loss of selectivity. A greenhouse gas, carbon dioxide, is produced

as a by-product of the non-selective side reactions. A CFD integrated

multiscale method is developed for transport phenomena in both the solid and

fluid phases, for ethylene and n-butane oxidation reactions. CFD is coupled

with microkinetic models and aniotropic pellet diffusivity to study selectivity

and catalytic activity loss inside the reactor, and their connections to

elementary reaction steps, temperature, and catalyst structure. To date, no CFD

study has coupled detailed reaction kinetics inside the catalyst particles with

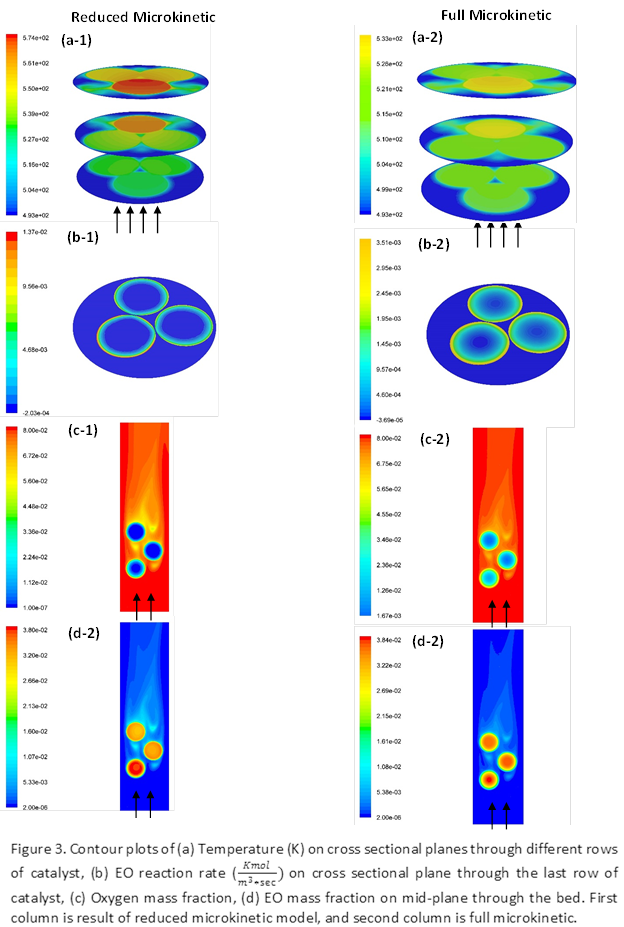

transport phenomena in the reactor. 2-Coupling microkinetics with CFD

Two different methods were developed to

couple microkinetic models with CFD. Initially, the proposed microkinetic

models were reduced to a single general reaction rate expression model. Later,

a method was developed and implemented to couple the full microkinetic model

with CFD.

The procedure of developing a general

rate expression for a microkinetic model is straightforward. The approach

includes several kinetic and mathematical assumptions to overcome the

complexity of the existing models. A reduced model for ethylene oxidation (EO)

based on a literature microkinetic model was obtained. Furthermore, literature

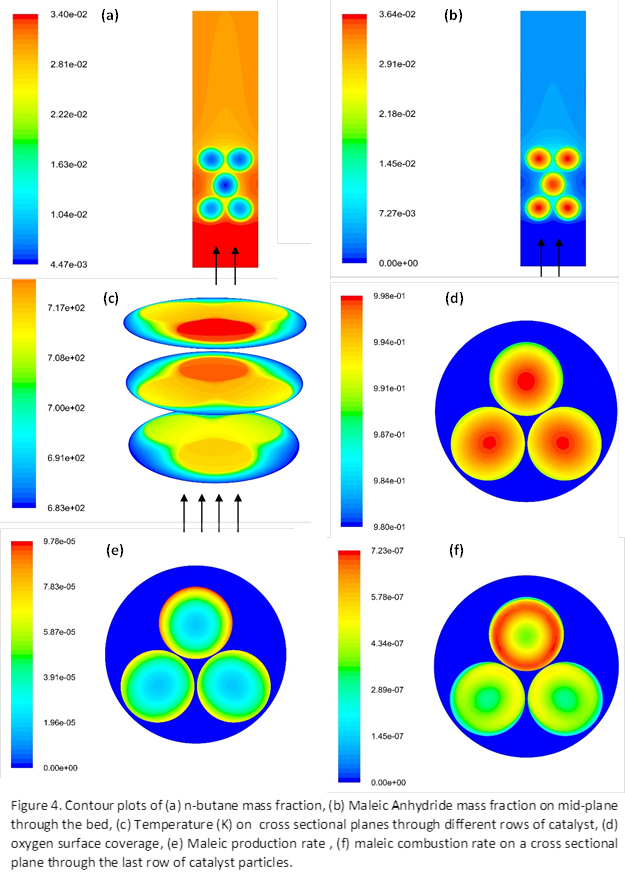

reduced models developed for n-butane oxidation were used for the maleic anhydride

reactor. To our knowledge these are the most comprehensive kinetic models existing

in the literature for the reactions of interest.

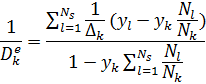

For the full microkinetic model of EO,

initially a sensitivity analysis was performed to evaluate the crucial

parameters to the model. Next, the model was solved over a wide range of

temperatures (T) and species partial pressures (Pi).

Reaction rates were then mapped into quadratic splines, and spline coefficients

were stored in a UDF as 1-D arrays. Finally, as CFD simulations were carried

out, for each computational cell, splines were constructed based on the

corresponding T and Pi to evaluate reaction rates.

3-CFD simulations

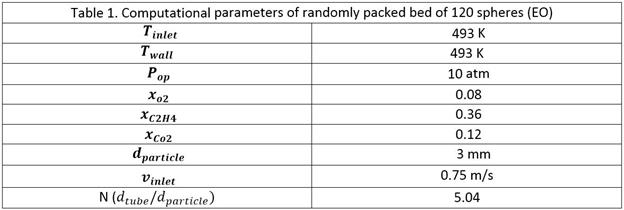

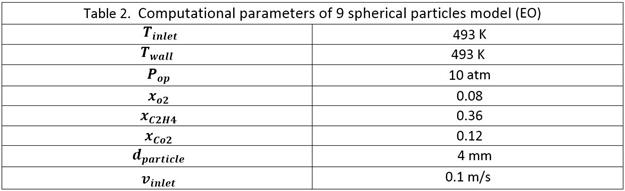

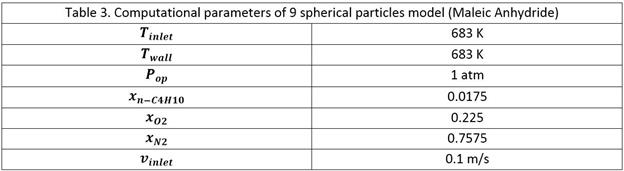

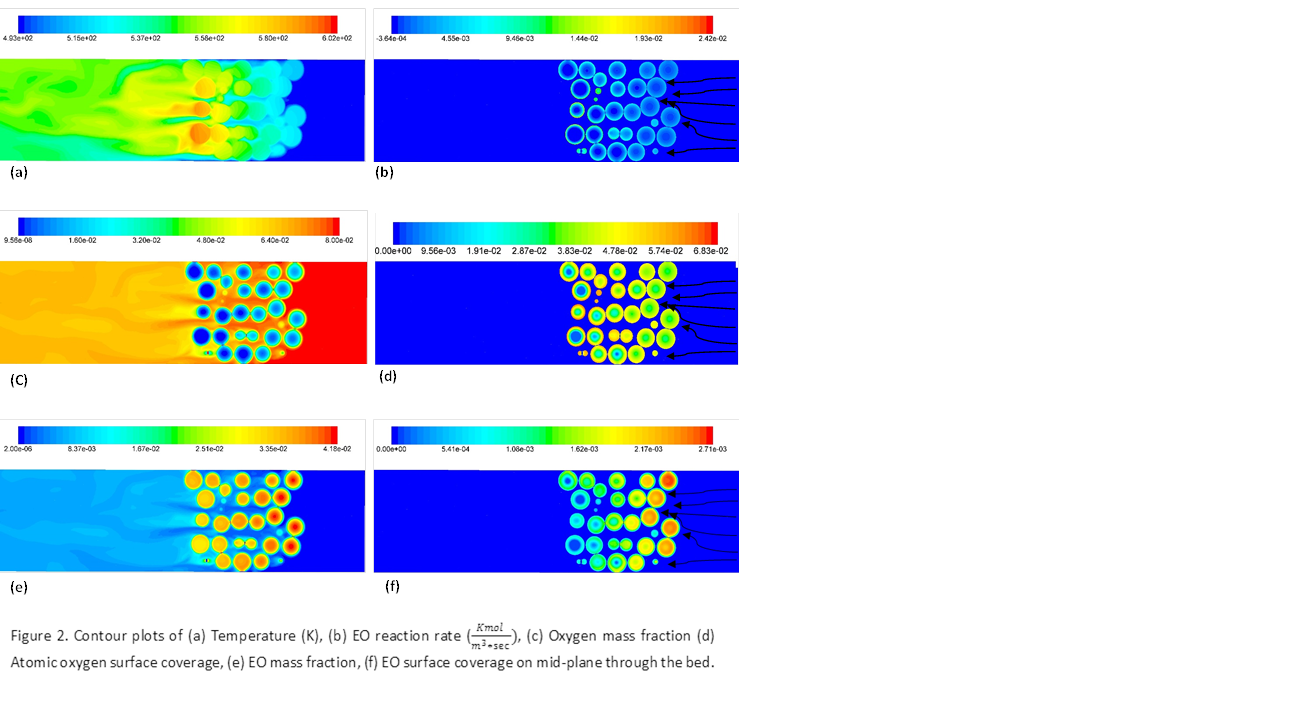

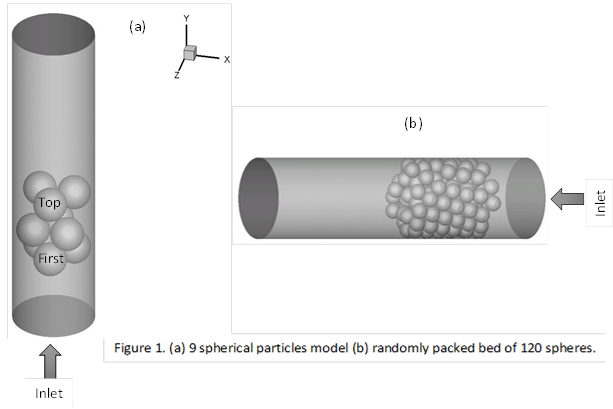

Two models are used for our studies

as shown in Figure-1.

3-1-Ethylene oxidation

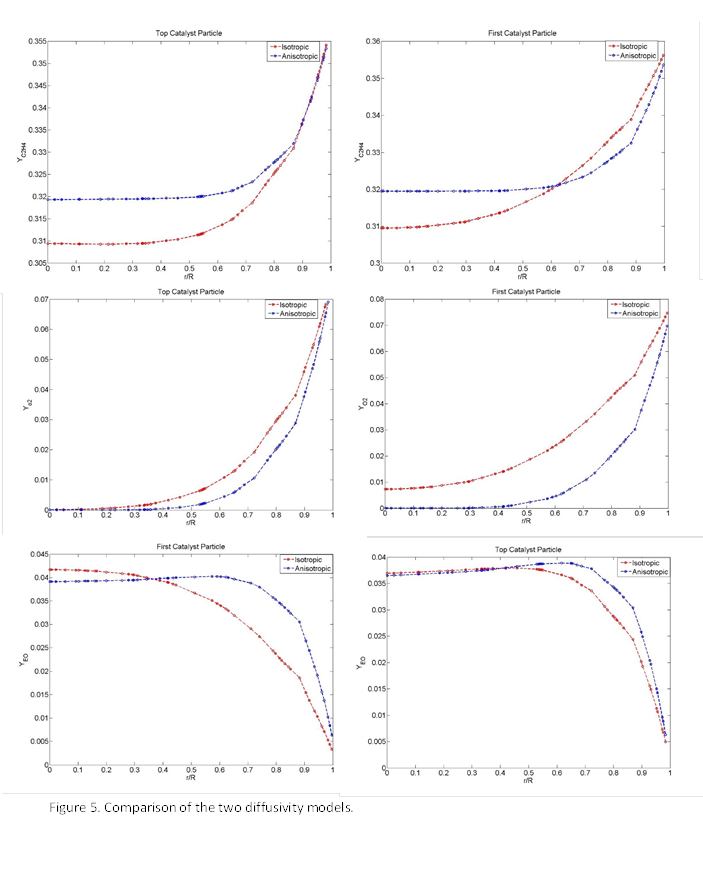

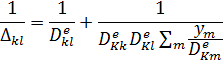

4-Improving the Effective Pellet Diffusivity

4-Improving the Effective Pellet Diffusivity

| |  | |

| |  |

| | |