Reports: ND454262-ND4: Reaction Mechanism of C-H Activation of Fe-Catalysts

Junrong Zheng, Rice University

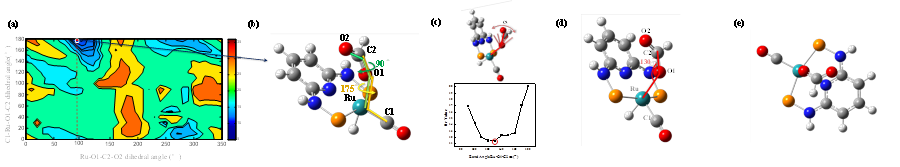

In the first fiscal year (09/2014-08/2015) supported by the ACS PRF grant PRF# 54262-ND4, my group achieved a significant accomplishment: for the first time, we demonstrated that the 3D structures of reaction intermediates which are too fast for NMR to measure can be determined by our vibrational cross angle method.

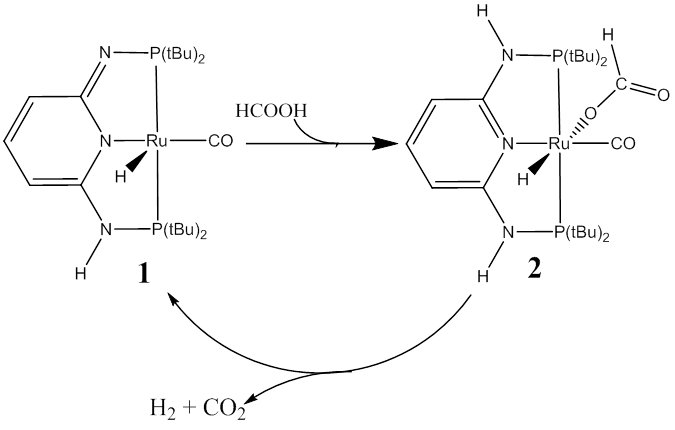

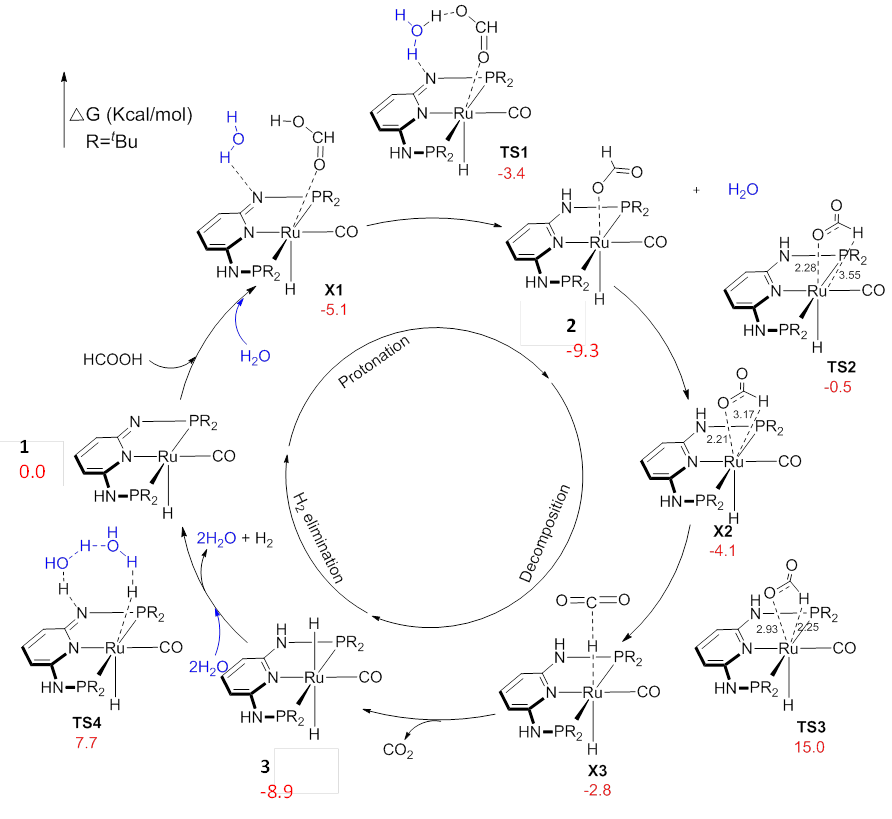

The reaction system investigated in this work

is the generation of hydrogen gas by decomposing formic acid, catalyzed by a

ruthenium PN3-pincer complex (

The decomposition of formic acid with the

presence of catalyst

This model system study allows us to explore all aspects of our method in determining reaction intermediate structures, which will be applied to the studies of other catalytic systems including the Fe-nonheme C-H activation catalysts in the near future.