Reports: DNI753780-DNI7: Tunable Temperature-Responsive Surface Morphologies of Polymer Heterostructures

Jianliang Xiao, PhD, University of Colorado Boulder

Shape memory polymers (SMPs) can memorize different shapes and recover to their original shapes upon appropriate stimulations, including heat, humidity, electrical and magnetic field. This study was to realize tunable temperature-responsive surface morphologies of polymer heterostructures by harnessing instabilities of shape memory polymer (SMP) thin films on compliant Polydimethylsiloxane (PDMS) substrates.

PDMS substrate was made from Sylgard 184 elastomer kit (Dow Corning) using a 20: 1 prepolymer-crosslinker ratio by weight. To synthesize SMP thin films, monomer tert-butyl acrylate (tBA) and cross linker poly (ethylene glycol) dimethacrylate (PEGDMA) were mixed at a ratio of 4:1 by weight, and 2, 2-dimethoxy-2-phenylacetophenone was added as the photo initiator. The glass transition temperature Tg of SMP made at this ratio is 42 0C. Polymer solution was injected into a mold, which was made by two glass slides with shims between them. Thicknesses of SMP thin films were determined by the shims. The mold with polymer solution was then placed under UV lamp for 5 minutes for polymerization followed by post-curing in oven at 80 0C for 1 hour. And then SMP sheet was demolded and cut into rectangular shapes with dimension of 15x5 mm. Film thicknesses were between 5~15 µm, measured by profilometer. The last step before proceeding wrinkling cycle was to transfer SMP thin films on top of PDMS slabs in room temperature.

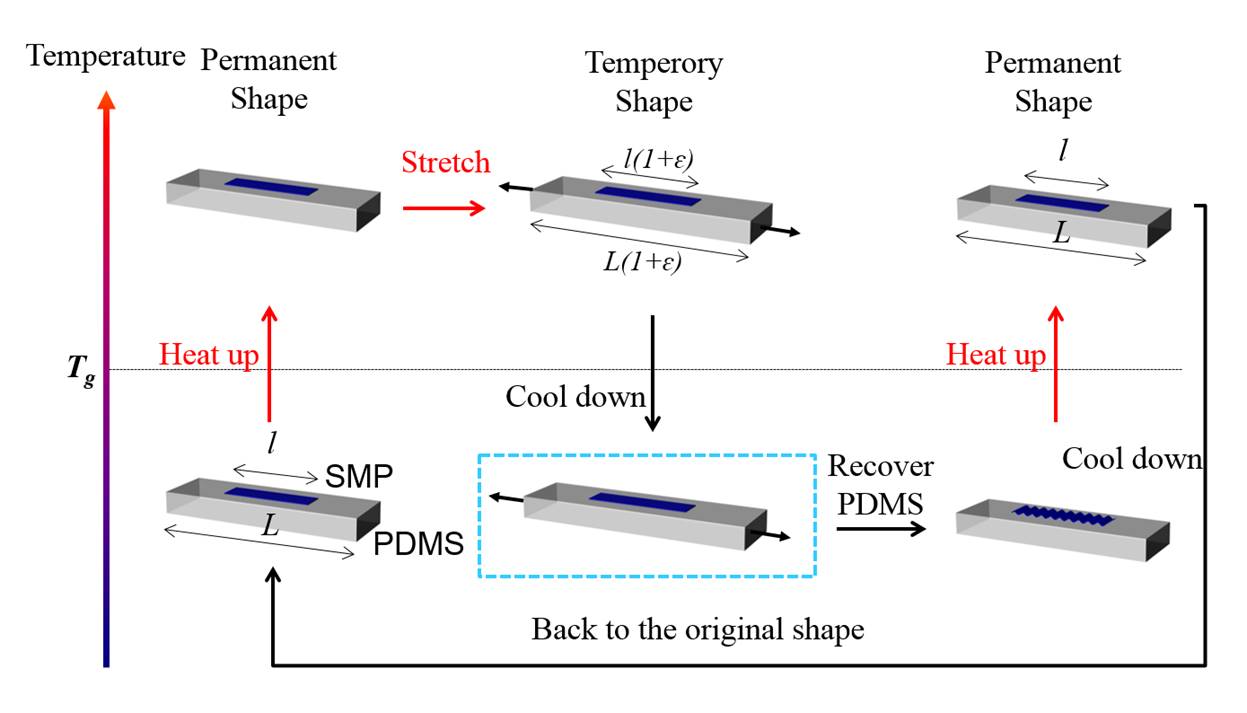

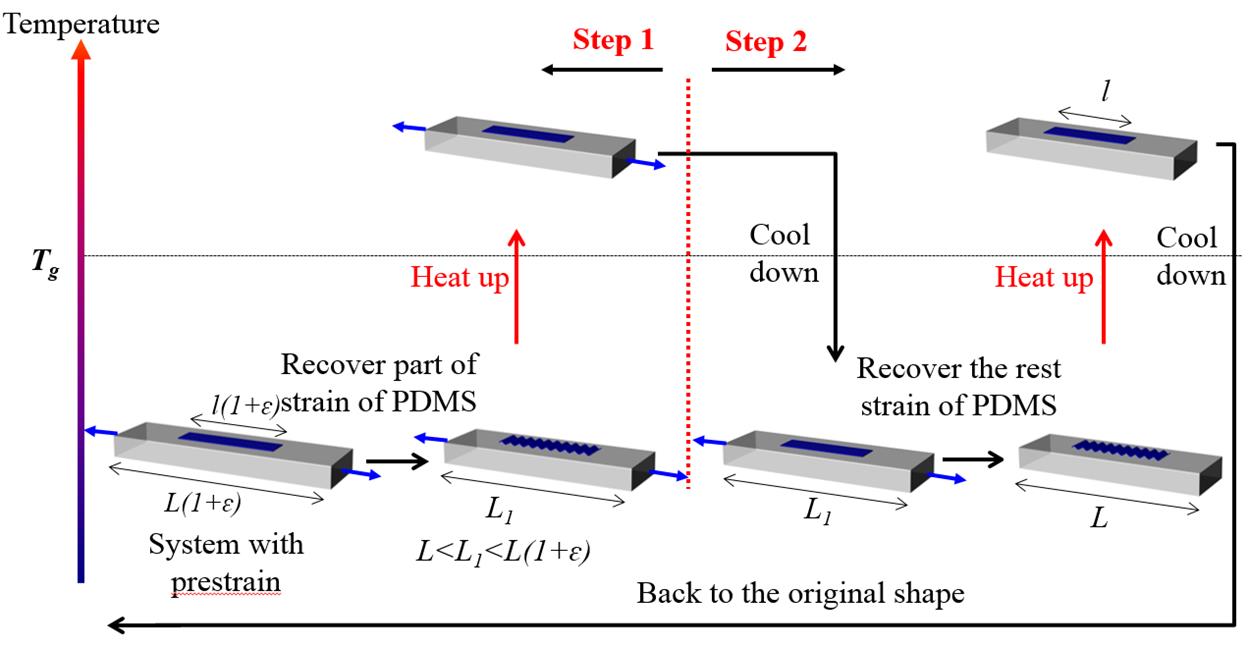

Fig. 1. Processes of realizing tunable SMP thin film wrinkles on PDMS

The permanent configuration of the system was when a SMP thin film was transferred onto PDMS substrate. Then the film-substrate system was heated to 60 0C firstly, higher than Tg of SMP. Then SMP film was stretched together with PDMS due to their bonding. The system with constraint was cooled down to room temperature to fix the strain in the SMP film. Now, the temporary shape of the SMP film was obtained with programmed strain. Subsequently, the stretch applied on PDMS was released at room temperature, the SMP thin film wrinkled on top of the PDMS substrate. When the system was heated again, strain in SMP film was recovered and the wrinkling disappeared spontaneously. Both the SMP thin film and PDMS substrate returned to their original shapes and were ready for new cycles. This wrinkling cycle can be repeated for many times. And the strain in each cycle can be different, yielding tunable surface morphologies.

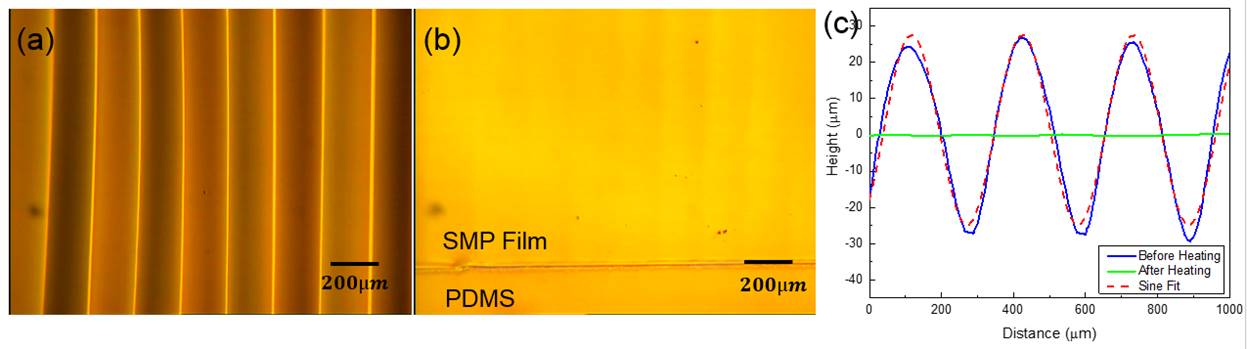

Fig. 2. Optical images of the wrinkled (a) and recovered (b) SMP thin film on PDMS, (c) The profiles of wrinkled SMP thin film on PDMS before heating and flat SMP thin film after heating.

Figure 2a shows an optical image of the wrinkling morphology of the SMP thin film of thickness 5.1 µm on PDMS. Figure 2b is an optical image of the recovered system, which clearly shows almost perfect flat surface morphology. Figure 2c shows the profilometer measured profiles of the wrinkling morphology (blue curve) of SMP thin film before heating and the flat morphology after heating (green curve). The wrinkling morphology shows excellent agreement with sinusoidal profile (red dashed curve).

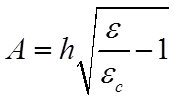

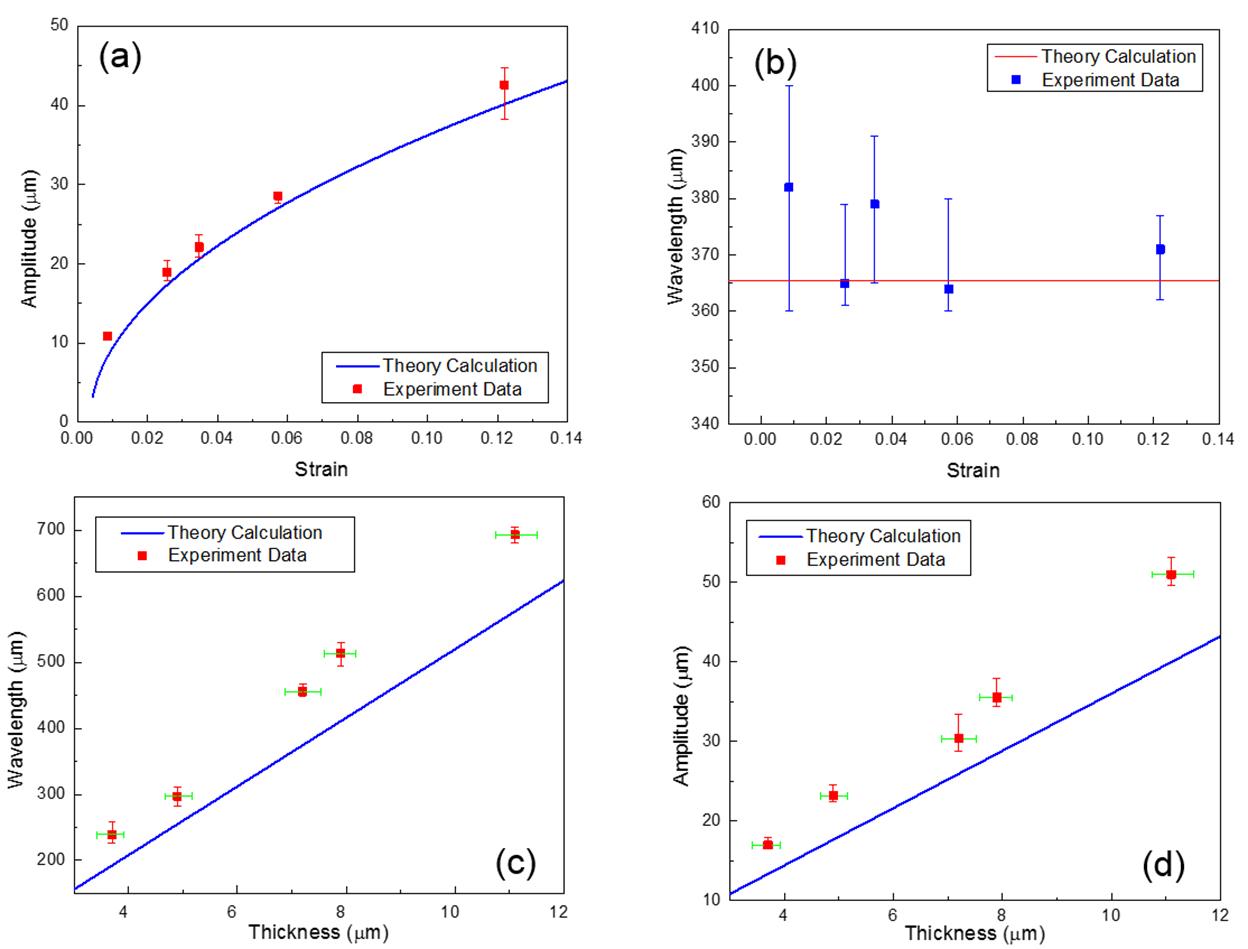

Figure 3a shows the relationship between the wrinkling amplitude versus the programming strain in different tuning cycles, which agrees very well with theoretical predictions given by wrinkling mechanics:

where h is the thin film thickness, ![]() is the critical wrinkling strain, and

is the critical wrinkling strain, and ![]() and

and ![]() are the plane strain modulus of the substrate and the thin film, respectively. Figure 3b shows that the wavelength remains unchanged for the strains applied in this study. The dependences of wrinkling wavelength and amplitude on film thickness are plotted in Figs. 3 (c) and (d), respectively. Experiment data show wavelength and amplitude increase linearly with film thickness, which agrees reasonably well with theoretical predictions given by wrinkling mechanics given in Eqs. (2) and (1).

are the plane strain modulus of the substrate and the thin film, respectively. Figure 3b shows that the wavelength remains unchanged for the strains applied in this study. The dependences of wrinkling wavelength and amplitude on film thickness are plotted in Figs. 3 (c) and (d), respectively. Experiment data show wavelength and amplitude increase linearly with film thickness, which agrees reasonably well with theoretical predictions given by wrinkling mechanics given in Eqs. (2) and (1).

The discrepancies in Figs. 3c and 3d could be due to that the thermally responsive SMPs cannot be simply treated as linear elastic materials.

Fig. 3. The relationship between (a) wrinkling amplitude and prestrain, (b) wrinkling wavelength and prestrain, (c) wrinkling wavelength and thickness, and (d) wrinkling amplitude and thickness.

Fig. 4. Thermomechanical history of wrinkling cycle with two recovery steps.

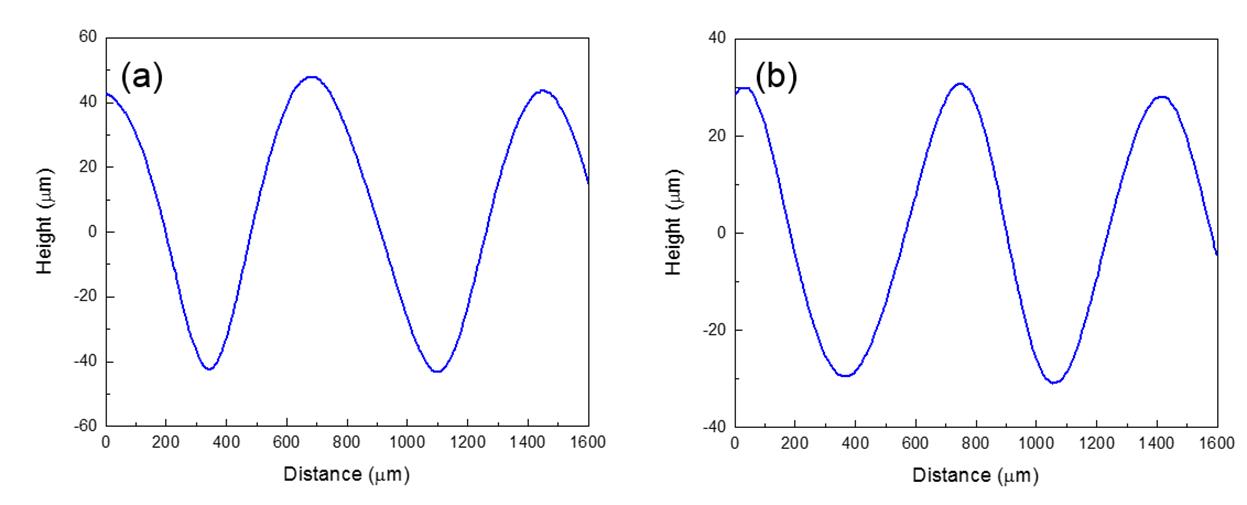

Here, we also demonstrate that strain in PDMS can be recovered in two steps, which makes film wrinkling formed and disappeared twice in a cycle. Procedure of this cycle is shown in Fig. 4. At room temperature, when partial prestrain of PDMS substrate was recovered, SMP film wrinkled for the first time (step 1 in Fig. 4). The wrinkling profile is shown in Fig. 5a. Wrinkling disappeared when system was heated to a temperature above Tg due to strain recovery of the film. At this time, strain of the film was equal to that of the substrate. After the system was cooled and the remaining strain in PDMS substrate was recovered, and the film wrinkled for the second time (step 2 in Fig. 4). The wrinkling profile is shown in Fig. 5b. Subsequently, the system was heated above Tg, the wrinkling disappeared due to SMP recovery and both film and substrate went back to their original length and got ready for next wrinkling cycle. This wrinkling cycle is repeatable, and the strain release in each step is controllable to tune the wrinkling profile. This strategy can be easily extended to a multi-step wrinkling cycle so that the wrinkling can form and disappear for multiple times in one cycle, and the profile of each step is controllable.

Fig. 5. The profiles of the wrinkled SMP film on PDMS in (a) Step 1 and (b) Step 2 in the wrinkling cycle illustrated in Fig. 4.

This research project has generated results that can have potential applications in smart adhesion, sensors, stimuli-responsive optical gratings, precision metrology and tunable microlens arrays. It also led to a new direction in the PI's research group to study tunable hierarchical surface wrinkling and its coupling with optics.