Reports: DNI1054717-DNI10: Electrohydrodynamically Assisted Dimensional Transition of Crumpled Graphene Balls at Interfaces: Toward Selective Removal of Aromatic and Organosulfur Containments

Vincent Tung, PhD, University of california, Merced

In this report period, the 2nd year of ACS Petroleum Research Fund, we have made a major step forward to elucidate the underlying mechanism of assembling crumpled graphene monoliths, comprehensive characterization of their materials properties, and realization of scalable production in a way closely resembling the additive manufacturing (a.k.a., 3D printing) when paired with programmable x-y-z translational stages. Particularly, the monolithic materials, obtained from the ElectroHydroDynamic (EHD) approach that synergistically integrates external stimuli, e.g., electrostatic and capillary forces.

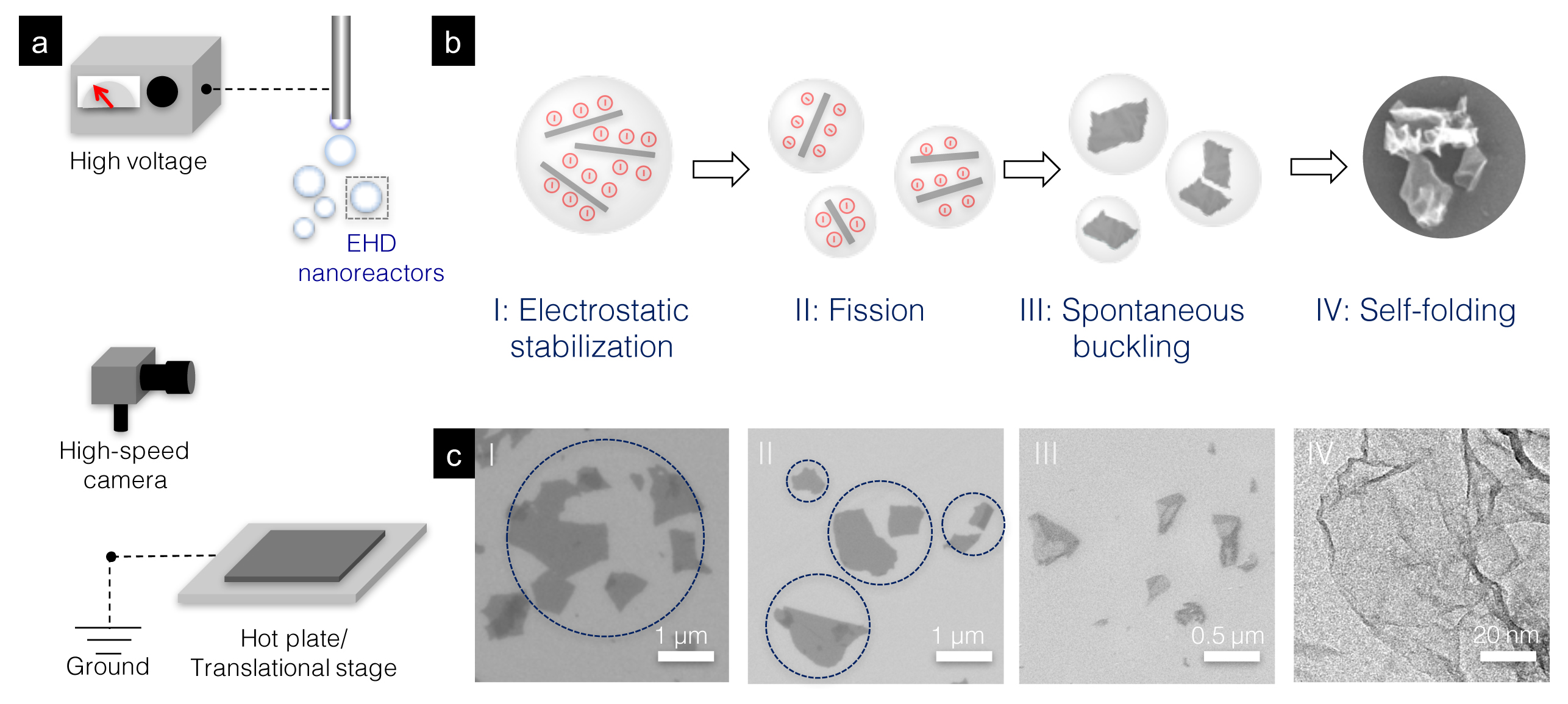

EHD process, which is typically employed for generating ultrafine droplets in high throughput thin film production (Figure 1a). Under a high electric field, the liquid medium deforms and then disintegrates into self-dispersing, charged droplets, providing electrostatically stabilized colloidal systems that inhibit graphene sheets from restacking. Further, EHD deposition is characterized by a droplet fission process, in which surface charge density drastically increases during solvent-evaporation-induced volumetric shrinkage, ultimately reaching the Rayleigh limit (Figure 1b). At this point, electrostatically charged droplets rupture into smaller ones with a diameter distribution in the sub-micrometer range. Thus, each fine droplet contains few- to single-layered graphene sheets before proceeding to a final stage of anisotropic self-crumpling. In addition to being a dispersing medium, these individualized, charged colloidal droplets can be considered soft templates that impose capillarity-induced geometric constraints to induce the crumpling of graphene sheets upon evaporation. In this light, graphene within these charged droplets will first separate into approximately individual sheets before being anisotropically compressed into crumpled nanostructures. The hierarchically porous nanostructure exhibits highly accessible surface-area (> 800 m2/g), which allows efficient exposure of both activated basal plane and edges. At nanoscale, the spatially distributed regions of local conformational strain, including facets, folds, ridges, vertices, and wrinkles at both atomic- and nano-scales, provides high concentrations of reaction sites for effective removal of aromatic containments, as shown in Figure 1c.

Figure 1. (a) Schematic drawing illustrates the setup of an EHD deposition for creating crumpled nanostructures. (b) Self-dispersing droplets can be viewed as individualized, freestanding colloidal nanoreactors that facilitate stages of (I) electrostatic stabilization of graphene, (II) fission, and (III) spontaneous buckling at both edges and basal plane or graphene, ultimately (IV) self-folding into crumpled nanostructures. (c) Corresponding HRSEM images corroborate the progressive transition from 2D graphene into 3D crumpled nanostructures. Specifically, HRTEM image reveals extremely thin and curved walls and a high degree of crumpling.

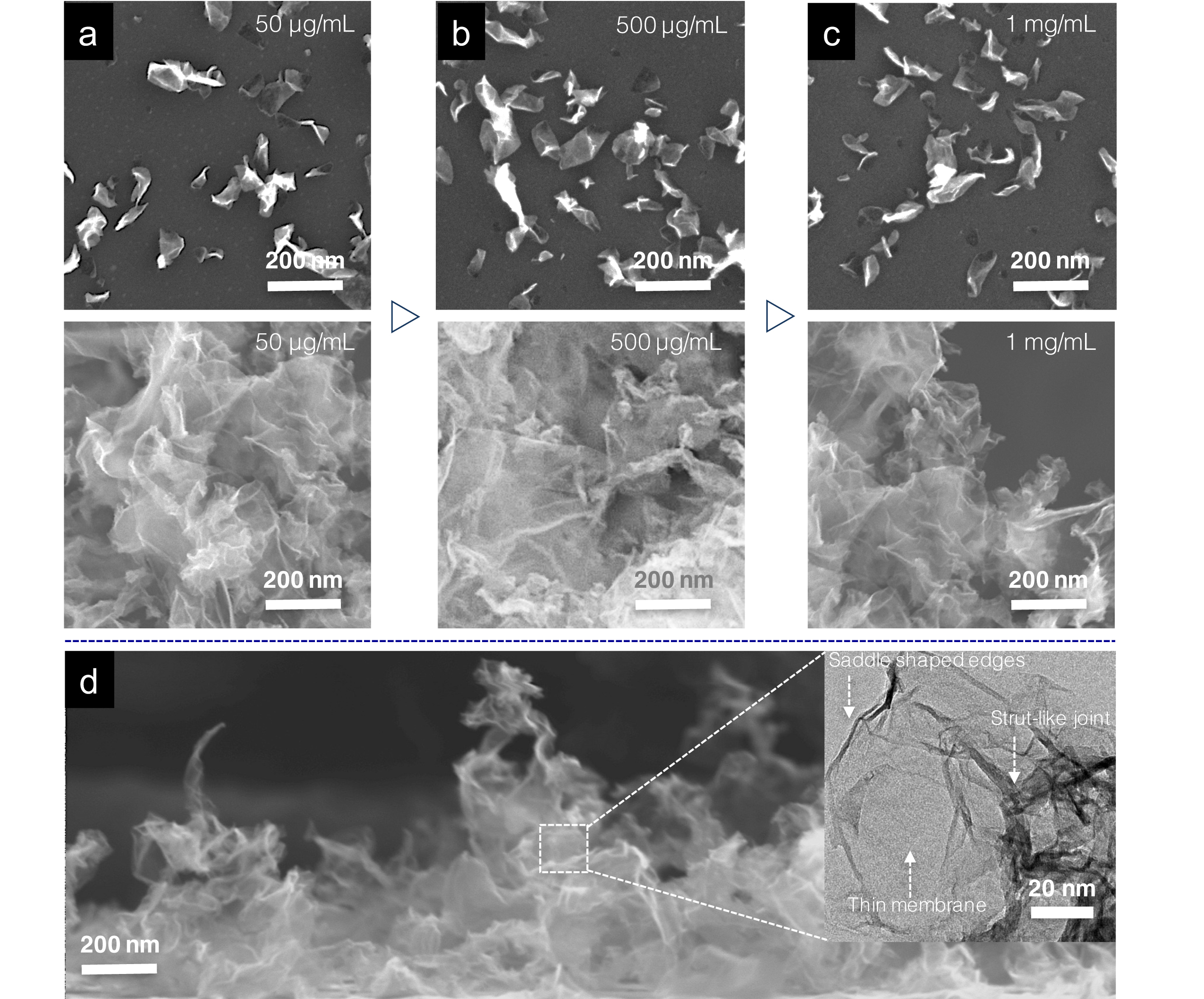

In parallel, cross-sectional SEM and TEM images collectively reveal the formation of hierarchically porous yet spatially interconnected foam-like monoliths, comprised of extremely thin graphitic membranes connected by corrugated or folded walls at the edges (Figure 2). Specifically, these strut-like joints not only function as stabilizers to preserve the structural integrity but also serve as electrical conduits for effective electron transport across foam-like morphology. Indeed, conductivity measurement confirms the establishment of electrically addressable pathways in both in-plane and out-of-plane directions. Our design of electrode showed separation channel lengths of 200 µm. The lateral conductivity of foam-like monoliths is found to be ~4.13 x 103 S/m and is similar to that of laser-scribed or liquid-mediated graphene papers. Meanwhile, out-of-plane conductivity measured via sandwiching monoliths of crumpled nanostructures between lithographically patterned electrodes also gives rise to a comparable value of 1.92 x 103 S/m. The comparable conductivity in both in-plane, and out-of-plane directions confirms the elimination of conductivity constriction points commonly encountered in crumpled nanostructures. In addition, the crumpled nanostructure can withstand a combination of high temperature annealing up to ~ 450ûC in ambient conditions and even common transferring process. It is noted that, however, the extremely thin crumpled nanostructures underwent an irreversible unfolding process during rehydration.

Figure 2. Degree of crumpling. (a) to (c) The degree of crumpling is found to be independent of the initial concentrations of graphene precursors as suggested in HRSEM images of individual crumpled nanostructures (top panel) and their assembly into foam-like monoliths (bottom panel) (d) Cross-sectional HRSEM image further suggests the formation of hierarchically porous and interconnected graphitic frameworks. (Inset, HRTEM image shows extremely thin and largely wrinkled walls connected by strut-like joints).

In summary, we demonstrated that EHD-generated droplets can be deemed as charged colloidal nanoreactors that combine two of most compelling forces in nature, e.g., electrostatic and capillary forces. Stimuli responsive 2D graphene sheets dispersed in these nanoreactors are found to undergo stages of electrostatic stabilization, fission, and spontaneous buckling, ultimately self-folding into 3D crumpled nanostructures with porous morphology. The predominant driving force for EHD-generated crumpled nanostructures is the loss of electrostatic stabilization. In contrast to the aerosol-assembled crumpled nanostructures that typically clump into a closed sphere with a hard texture, the morphology of resulting crumpled nanostructures bears a close resemblance to the blooming snapdragon flowers with an open structure and ripple shaped petals. Upon continuous deposition, these thin and adaptable crumpled nanostructures were found to dynamically deform into non-spherical, polyhedral shapes, ultimately creating foam-like microstructures with doubly curved, saddle shaped edges. Of particular importance is the convergence of high aspect ratio, improved conductivity in all directions, highly assessable surface area and energetically favorable interfaces makes crumpled nanostructures ideal candidates for efficient removal of aromatic containments. Prototypical experimental demonstration that explores the use of crumpled nanostructures as the active layers for aromatic absorber is current underway and will be reported in the next phase.

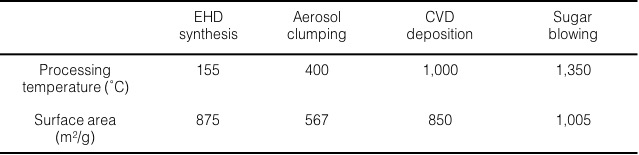

Table 1. EHD approach enables the low temperature processing and high surface area among the state-of-art graphene based porous monoliths, representing a giant step forward to bridge the gap between academic prototype and industrial standard.