Reports: DNI955379-DNI9: Thermo-Chemo-Mechanics of Swellable Elastomers

Shengqiang Cai, PhD, University of California, San Diego

Introduction

In the past year, we have mainly conducted experimental studies on the rupture of swollen elastomers (styrene-butadiene rubber) as planned in the proposal.

Swellable elastomers have been recently explored to make swellable packers in oil industry, which have many advantages over traditional cement packers. In the applications, the elastomers absorb solvent and swell against the confinement, which can seal zones in the borehole. In addition, elastomers are usually subjected to a large pressure difference, which can cause elastomer fracture. Following the proposed research plan, we conducted an experimental study of the rupture behavior of SBR swelled in hexadecane. Pure-shear tests are used to measure stretch at rupture and fracture energy of swollen SBR with different swelling ratios. It is found that both increase of swelling or decrease of stretch rate can significantly reduce stretch at rupture and fracture energy of SBR.

Experiments

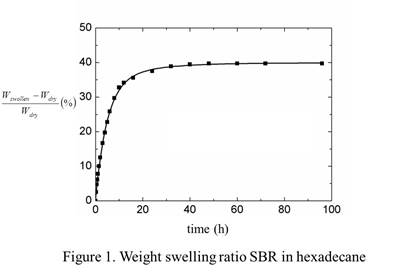

In the experiments, prior to mechanical tests, partially swollen elastomers are prepared and homogenized. The swelling kinetics of a SBR sheet in hexadecane is shown in Figure 1. Partially swollen SBR samples are taken out from solvent at several different times and wrapped in sealing plastic films for homogenization for 24 hours.

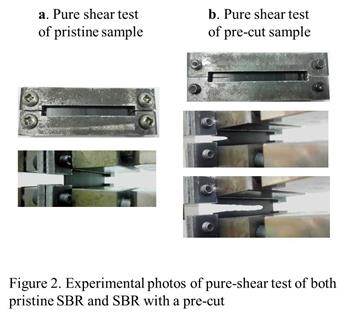

To measure the fracture energy of a

partially swollen elastomer, we perform experiments on the elastomers, following

the “pure-shear” method of Rivlin and Thomas. In

mechanical test, both pristine samples (no pre-cut) and samples with a pre-cut

are tested in “pure-shear” geometries, as shown in Figure 2. Samples are

stretched in the direction along the height of the sample at several different rates

of extension using an Instron model 5965. Tensile

stress vs stretch curves of different samples were measured. In the pristine samples, the stretch at rupture

can be easily detectable. The stretch at rupture in the samples with pre-cut is

defined by the moment that the crack starts to propagate. As described by Rivilin and Thomas, for a pure-shear test specimen with a

pre-cut, the fracture energy

![]()

where

![]()

![]()

Results and Discussions

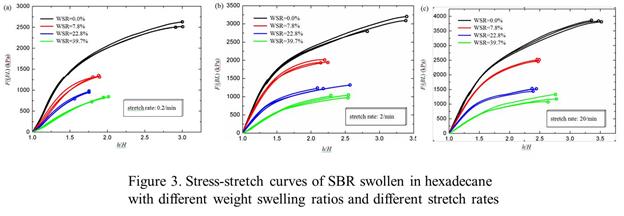

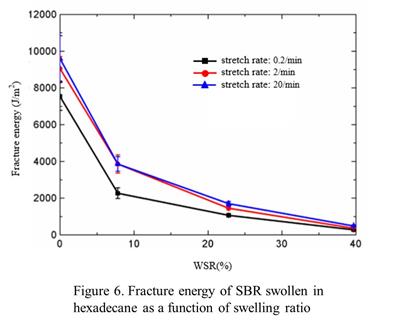

Figure 3(a-c) plot the stress-stretch curves of pristine SBR with different swelling ratios under pure shear tests. We found that with increasing the swelling ratio, stiffness, stretchability and strength of SBR all decrease for the three different stretch rates in our experiments. Figure 4(a-c) plot the stress-stretch curves of swollen SBR with a precut as shown in Figure 2 under pure shear tests.

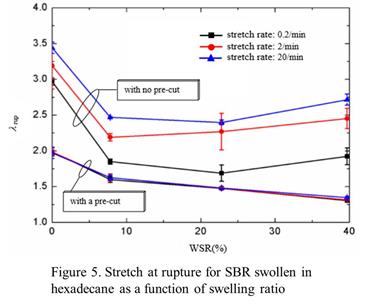

Figure

5 summarizes the stretch at rupture for both pristine and pre-cut SBR with

different swelling ratios. We found that a pre-cut can drastically reduce the

stretch at rupture of SBR, which quantitatively describe the notch sensitivity

of SBR.

Figure

5 summarizes the stretch at rupture for both pristine and pre-cut SBR with

different swelling ratios. We found that a pre-cut can drastically reduce the

stretch at rupture of SBR, which quantitatively describe the notch sensitivity

of SBR.

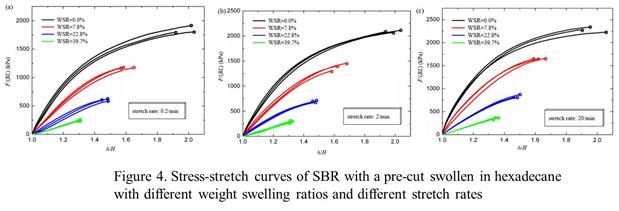

Based on the measurement and Equation (1), fracture energies of SBR with different swelling ratios and stretch rates were obtained as summarized in Figure 6. With increasing the amount of solvent in the rubber network, the energy dissipated due to the sliding of polymer chains decreases. Consequently, fracture energy of SBR decreases with the increase of swelling ratio.

Conclusions

We measured fracture energy of swollen elastomers using pure shear test. The fracture energy of SBR obtained in pure shear test can be used to predict the fracture of SBR with arbitrary geometries and general loading conditions. The method developed in our study can be also used to measure fracture energy of different swellable elastomers in different environmental conditions.