Reports: ND1054550-ND10: Electrode Stability in High Temperature Sensors for Petroleum Applications

Jacob L. Jones, North Carolina State University

Abstract: Solid-state dewetting of 10 and 15 nm Au thin films on indium tin oxide (ITO)/glass substrates was investigated. Films were prepared by sputter coating and thermally annealed in a nitrogen atmosphere tube furnace. Scanning electron microscopy (SEM) and atomic force microscopy (AFM) analyses exhibited the heterogeneous formation of holes and their subsequent growth and impingement by diffusion. The rate of hole growth was strongly influenced by annealing temperature and thickness. Temperatures lower than 400°C suppressed nanoparticle separation within the 120 minute time-scale. AFM and grazing incidence x-ray diffraction (XRD) also revealed with long annealing times, close to two hours, and high annealing temperatures, upwards of 600°C, there was a height drop in the Au islands relative to the substrate suggesting diffusion through the interface between Au and ITO. This effect was further explored and corroborated through a transmission electron microscopy (TEM) cross-section. These results provide a detailed look at time and temperature dependence of morphology of Au thin films on ITO and can be significant in controlling contact area for metallic electrodes, etch masks, plasmonic transducers etc.

Introduction: Metallic thin films, such as gold and platinum, are widely used in the metallization of non-conducting surfaces or semiconductor devices owing to their high conductivity and low reactivity. Unfortunately, high temperature processing and operation can initiate damage via solid state dewetting. The repeated operation of devices can often lead to resistive heating where local temperatures can be high enough to have the same effect. This can be detrimental, particularly as devices dimensions continue to shrink well into the nanoscale. This project has investigated some of the fundamentals of the dewetting process.

Experimental: Commercially available substrates of 1cm boro-aluminosilicate glass with 145 nm sputter coated indium tin oxide (ITO) (91 wt% In2O3, 9 wt% SnO2) were used here. These were prepared by ultrasonic cleaning with acetone, followed by methanol and dried with compressed air. 10/ 15 nm of gold was sputter coated using an Emitech 550X in an Ar atmosphere at room temperature. Films were thermally annealed on an alumina crucible in a Cole Parmer tube furnace in nitrogen with a gas flow rate of 110 sccm for times of 5, 20, 40, 60 & 120 mins at elevated temperatures. Samples were air-quenched to room temperature.

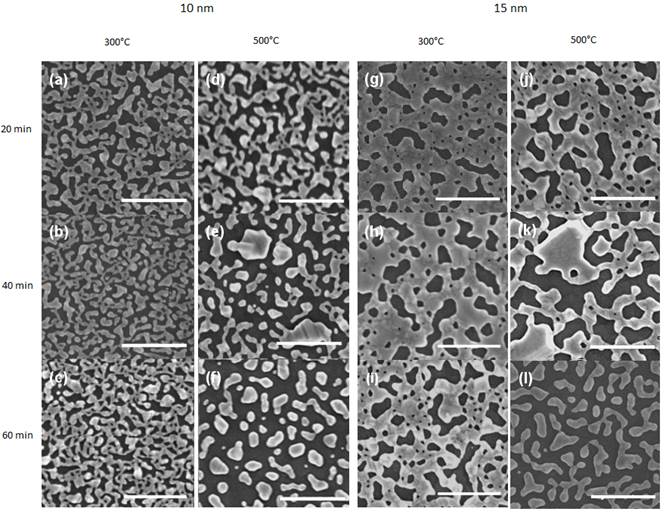

Results: Dewetting is primarily driven by a reduction in interfacial energy to reach a more favorable thermodynamic state. Fig 1 presents the transformation of 10 nm and 15 nm films respectively at 300°C and 500°C for 20, 40 and 60 mins.

Figure 1. Morphology of 10 nm (a-f) and 15 nm (g-l) films at temperatures 300/500°C for times 20, 40, 60 mins. All scale bars 500nm.

With a thickness variation of 5 nm, there is a noticeable difference between the two groups in terms of microstructure. After heating for 60 mins at 300°C (figure 1(c,i)), for example, the 10nm film retains only thin branches with a high density of holes while the thicker film remains continuous. The effect of time is most apparent at the higher temperature of 500°C with 15 nm films as seen in figure 1 (j-l), where we are able to clearly track the evolution in morphology during heating from concurrent hole initiation and impingement in 20 mins, to significant branching that can be seen in 40 mins, to a highly separated film in 60 mins. Additional analysis of these morphological changes was undertaken but is not included in this report due to space limitations.

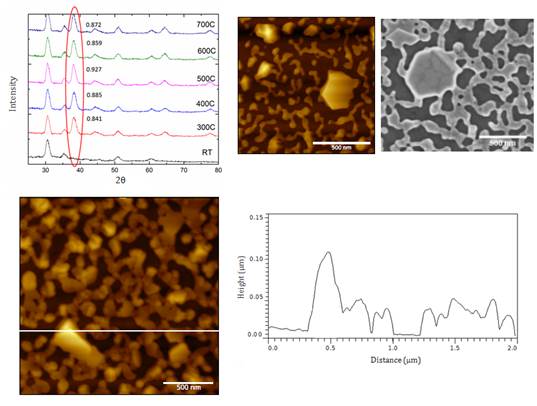

We used ex-situ grazing incidence XRD to examine the texture of select 15nm films and AFM to investigate surface morphology (figure 2). In prior work, an increase and subsequent plateau of Ag (111) count was seen to match the observed changes in height of Ag films during agglomeration. This correlation would be supported by the emergence of the highlighted peak in figure 2 following annealing in our results.

Figure 2. Au (111) peaks are circled and intensity was calculated relative to ITO (222) to its left. Large, faceted particles begin to form during the branched stages and continue to grow until the branches are disconnected. All scale bars 500 nm.

At the stage where the dominant microstructure is branched, there are large multi-granular particles that appear recurrently. The preferential growth direction in Au films is manifested in these large particles by reducing surface energies more quickly than would be achieved in growth of branches. By the height profile in figure 2, we observe that they are close to 50 nm above their surrounding ligaments and 300-600 nm in diameter. Faceting is visible in the SEM and AFM images shown here. Pronounced faceting on Au particles has been commonly seen on many different substrates and attributed to its high surface energy anisotropy with faces sitting most prominently on (111) and (100) planes.

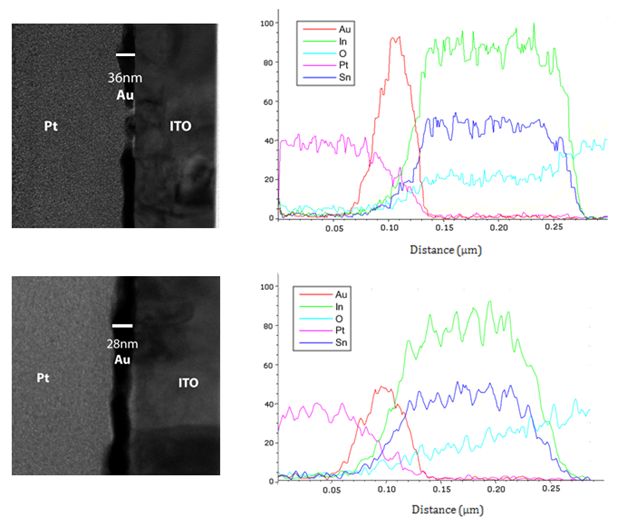

The results of our studies at longer annealing times, as shown in AFM, and at high temperatures, as shown in XRD, led us to believe there were new mechanisms in operation at these harsher heating conditions in the Au-ITO system. Cross-sectional lamellae were cut and examined in TEM to acquire an image and chemical analysis of this interface, shown in figure 3.

Figure 3. TEM cross sections and corresponding EDS of 15 nm films

annealed at 300°C for 60 min (top) and 120 min (bottom)

EDS shows there is a shorter and broader Au peak in the sample with longer annealing time. The height drop detected in the islands coupled with broadening of the Au peak in the cross-sectional EDS analysis, collectively suggest that there may be chemical interaction occurring between the gold and ITO. By examination of the phase diagrams of Au-In and Au-Sn, both In and Sn have a degree of solubility in Au. This interdiffusion likely significantly influences the dewetting process and is currently being explored further.