Reports: ND753386-ND7: Buckling-Induced Morphological Transformations in Block Copolymers

Sachin Velankar, University of Pittsburgh

When a thin stiff film bonded to a softer substrate is compressed, it buckles and develops numerous wrinkles. Such wrinkled surfaces have numerous potential applications as smart surfaces with tunable adhesion, friction or wettability, flexible electronics, or mechanical tenability. This project sought to transplant these phenomena of thin film buckling to develop buckled materials. More broadly, the existing research was is dominated by purely-elastic (often linearly elastic) materials, whereas real polymeric materials have more complex mechanical behavior including viscoelasticity, yielding behavior, strain hardening, or indeed even viscous behavior (under molten conditions). Moreover by changing temperature, polymers can be readily switched from one kind of behavior to another. The overall goal then is to exploit such realistic material behavior to develop new materials.

Over the course of this grant, we initiated two research directions: research on layered composites comprising layers of plastic and elastic materials, and research on block copolymer films, and here we will briefly discuss each.

Layered polymeric systems

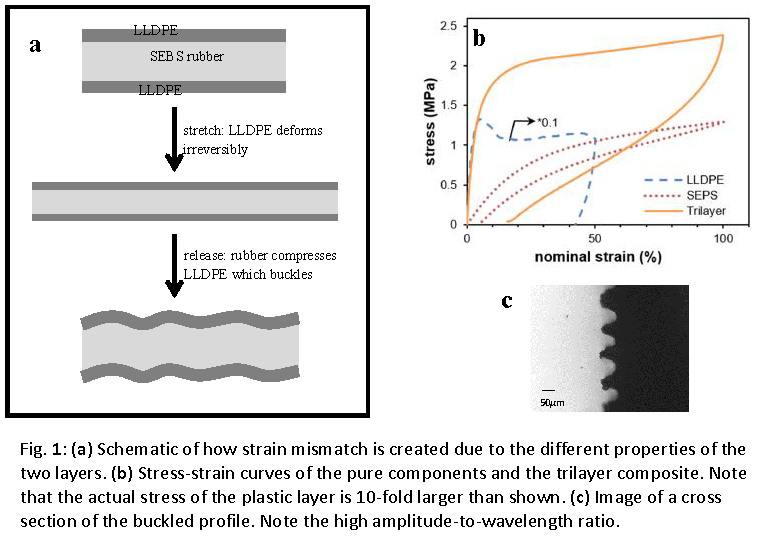

Experiments were conducted by bonding thin layers of linear low-density polyethylene (LLDPE) to both surfaces of thick sheets of styrene-ethylene/butylene-styrene rubber (SEBS), and then stretching the trilayer. Since LLDPE shows a large plastic deformation whereas the rubber shows large elastic deformation, at the end of the stretching process, there is a geometric mismatch within the sample: the plastic layer is longer than the rubber. Upon releasing, the rubber layer applies a compressive stress on the plastic, which then buckles.

Fig. 1a illustrates the basic strain history applied. Fig. 1b compares the tensile load-strain curves of each layer individually, as well as a plastic-rubber-plastic trilayer, whereas Fig. 1C shows an example of the buckle profile. We have measured the dependence of wavelength and amplitude on the strain and on the geometric parameters. What is most useful is that large amplitude to wavelength ratios (~0.5) can realized. Wrinkled surfaces have numerous potential applications, but most past experiments are unable to reach aspect amplitude to wavelength ratios of 0.3.

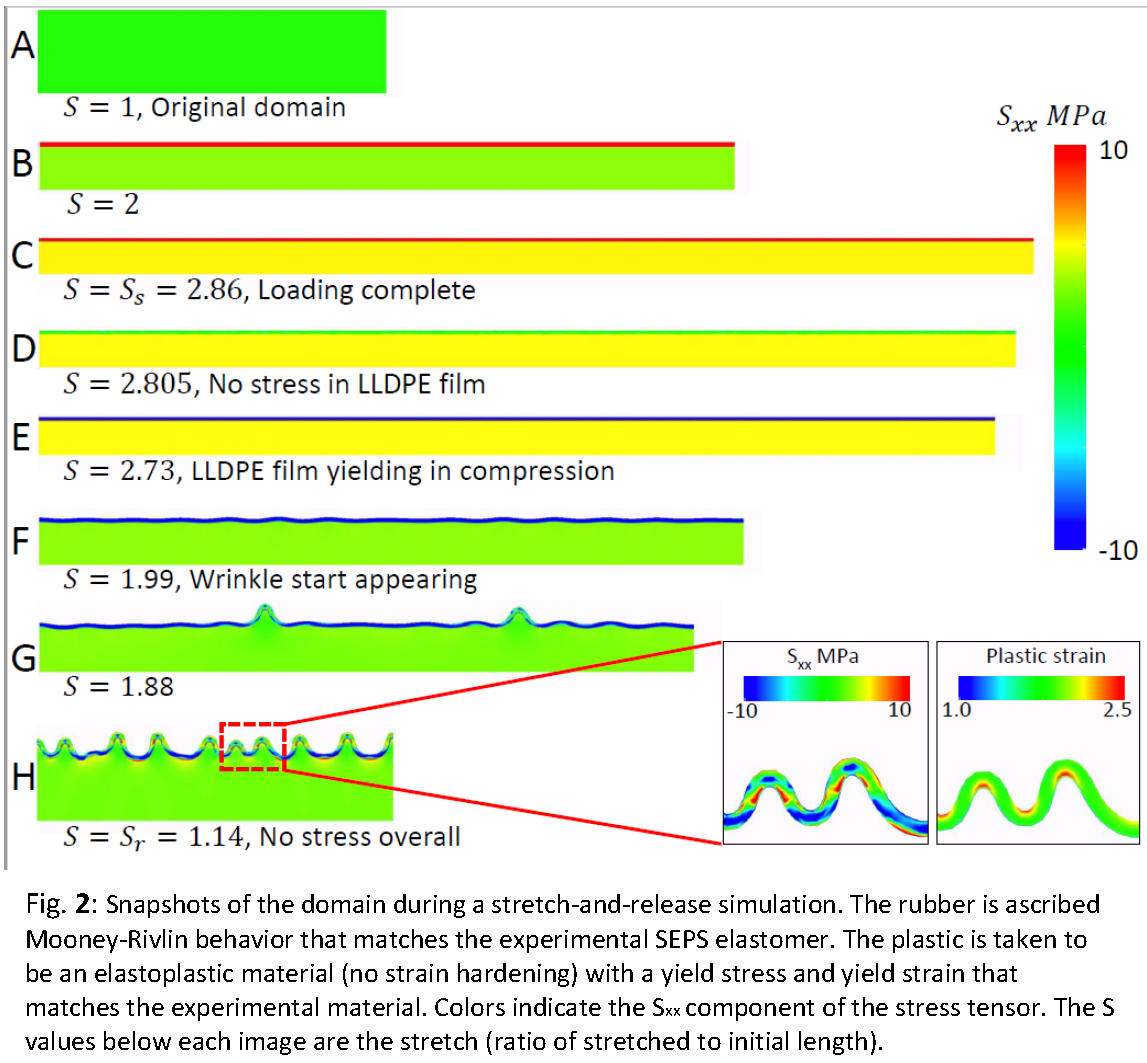

In collaboration with Prof. Spandan Maiti (Dept. of Bioengineering, University of Pittsburgh), we have conducted finite element simulations of the same. The results, illustrated in Fig. 2, suggest that buckling in such plastic-elastic combinations is fundamentally different from that in elastic-elastic combinations. Specifically, plasticity plays a key role at all stages in this process (1) Most obviously, plasticity creates the geometric mismatch in the first place, (2) The film yields in compression during the release process (Fig. 2 D&E), (3) Plastic hinges appear due to localized yielding at the points of high curvature (Fig. 2H), and (4) if the yield stress is higher, the plastic film undergoes localized necking during deformation itself (not shown). These results are now in a manuscript submitted (in revision) to Soft Matter.

Block copolymers

We initiated research on styrene-butadiene triblock copolymer (SBS) copolymer with a morphology consisting of polystyrene (PS) cylinders in a polybutadiene matrix. We developed protocols to align the cylinders, and then crosslink the films. The core of the studies then were to subject such crosslinked films to a specific thermomechanical history intended to develop internal stress in the samples, specifically, to subject the PS cylinders to compressive stress. The hypothesis was (analogous to Fig. 1) induce buckling of the PS cylinders, thereby converting an ordinary cylindrical morphology into a more complex buckled morphology. Experiments were conducted using block copolymer (Dexco Vector 8508A, with 29% styrene) with a cylindrical morphology was aligned uniaxially by planar compression under molten conditions, followed by immersion into mixture of crosslinker and photoinitator, and then crosslinking by a thiol-ene reaction. Early mechanical testing experiments using an extensional rheometer were promising. Accordingly, we conducted Synchrotron SAXS studies of the same. These results however were disappointing: they showed no evidence of a buckled morphology. We hypothesize that exactly the same phenomena pointed out above, and more specifically, the ability to accommodate compression by plastic deformation, is the reason why a buckled morphology did not result. I.e. our original idea that both the polystyrene cylinders and the rubbery butadiene continuous phase of the block copolymer would behave elastically may be incorrect; instead we believe that the polystyrene is able to deform plastically, and thus avoid buckling

Looking ahead

The funding from the ACS grant allowed the PI to pursue several explorations in the general area of buckled materials, and to establish collaborations. The preliminary results were critical in obtaining funding on the mechanics of thin polymer films. Additional funding has been through two grants, both from the National Science Foundation. One, along with Prof. Rui Huang (UTexas) is on the buckling of thin films bonded to viscoelastic substrates. The second, along with Prof. Spandan Maiti (UPittsburgh) is on toughening of multilayered films by combining polymers with plastic and elastic behaviors. Thus, the New Directions grant was critical in establishing this new research area in the PI’s lab.