Reports: ND953313-ND9: Methods for Closed-Loop Chemical Production Scheduling

Christos Maravelias, Universtiy of Wisconsin (Madison)

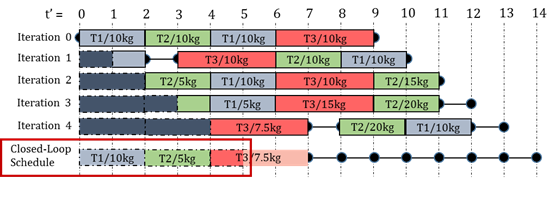

Process industries employ a complex chain of operations to produce finished products. These processes (tasks) compete for limited resources. Hence a resource allocation problem arises wherein decisions with regards to how much to process, the start time of operation, the equipment to utilize and various other associated decisions need to be taken on a repetitive basis. Traditionally, schedules have been constructed by experienced scheduling personnel with assistance from spreadsheets. In the last two decades there has been an increasing thrust towards using advanced computational tools to achieve better schedules. However, although the process systems engineering community has worked on building accurate models and better solution methods, the aspect of repetitive scheduling has received limited attention. In a dynamic environment multiple disturbances to implemented schedule are seen, which necessitate taking recourse actions to find the best operating schedule for the current scenario that has realized. Disturbances such as task delays, yield losses, unit breakdowns or rush order arrival can render a previously computed schedule suboptimal. Accordingly, the goal of this project was to (1) develop solution methods that would allow us to solve scheduling problems in time frames suitable for online scheduling; and (2) investigate how the design of the online scheduling problem (open-loop problem) affects the quality of the resulting repetitively modified and implemented schedule (closed-loop schedule) (Fig. 1).

Towards the first aim, we (1) developed a propagation algorithm based on time and inventory considerations that preprocess the data information and automatically generates valid inequalities that tighten the original mixed-integer programming formulations (Merchan and Maravelias, 2016); (2) developed solution methods for scheduling problems in multi-stage, multi-product batch facilities (Merchan et al., 2016); and (3) showed how various solution methods can be used to address medium- and large-scale scheduling problems (Velez et al., 2015).

Towards the second aim, we successfully created a computational framework through which we can quantify and analyze closed-loop schedules Gupta and Maravelias, 2016. Using this framework we studied the effect of the following attributes on the quality of the resulting closed loop schedule: (1) predictive horizon length, (2) frequency of re-scheduling, (3) suboptimal open-loop solutions, (4) objective function modifications, and (5) addition of constraints. In this work, we also showed that (1) open-loop and closed-loop scheduling are two different problems, even in the deterministic case, and (2) how equally good open-loop schedules can translate to very different closed-loop schedules.

Finally, in another manuscript we just submitted, we reviewed advances in the field of rescheduling. Through a series of examples, we showed that acting on new information, as soon as it becomes available, can be more important than acting on observed uncertainty in the current information. In fact, we provided an example to show that it is important to reschedule periodically, even when there are no “trigger” events, something that is in contrast with the current approaches to rescheduling. In addition, we formally defined the concept of online scheduling, and provided a classification framework for online scheduling approaches, including methods that rely solely on recourse through feedback as well as methods that account for uncertainty a priori.

The research supported by this ACS-PRF led to the publication of four peer reviewed journal papers (see references) and one submitted paper, as well as multiple conference presentations.