Reports: ND754047-ND7: Elucidate the Molecular Orgins of Mechanical Stress in Large Deformations of Polymer Glasses by Incorporating Chromophores into the Backbone as Molecular Probes

Abraham Joy, The University of Akron

Shi-Qing Wang, University of Akron

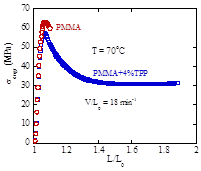

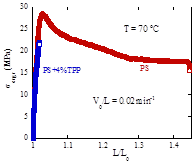

A. According to the conventional wisdom based on Eyring's idea about plastic flow, the effect of incorporating small-molecule plasticizers should be to make a polymer glass more ductile during cold drawing because the additives lower the overall glass transition temperature and accelerate segmental relaxation. Indeed, many polymer-plasticizer pairs satisfy this expectation as shown in Figure 1. However, our recent experiments reveal some counter-intuitive behavior that challenges the consensus. Polystyrene is ductile at 70 oC at a sufficiently low extensional rate and turns brittle upon incorporation of the same 4% TPP that has made PMMA more ductile in Figure 1. The opposite effects of TPP on PMMA and PS cannot be rationalized according using the existing knowledge.

Figure 1 Engineering stress sengr vs. draw ratio L/L0 from tensile extension at 70 oC of PMMA (circles) and plasticized PMMA (squares) by 4% of triphenyl phosphate (TPP) at an initial rate of 18 min-1.

Figure 2 Engineering stress sengr vs draw ratio L/L0 at an initial rate of 0.02 min-1 of both pure PS (circles) and plasticized PS (squares) at 70 oC.

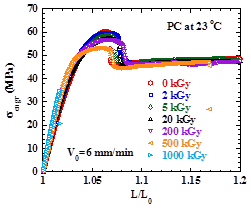

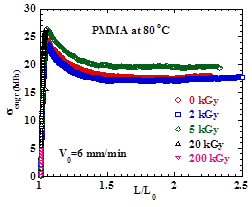

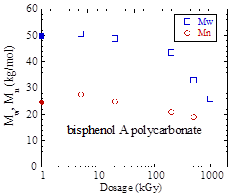

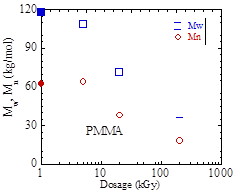

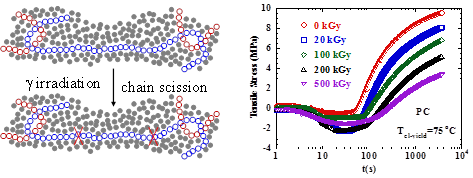

B. A cold-drawn polymer glass remains nearly as long as when the specimen was first unloaded from a stretcher. Hidden residual stress survives in such a specimen for days or years, evidenced by the negligible length shrinkage. The mechanical stress arising from tensile extension of polymer glasses may share the same microscopic origin with the residual stress. The residual stress shows up as retractive stress when such a cold-drawn polymer glass is annealed above the cold-drawing temperature. [4] We may determine the molecular origin of stress in ductile deformation of polymer glasses if we can induce chain scission in the pre-cold drawn polymers in a non-invasive manner and study the elastic yielding characteristics of the modified specimens. To this end, we resort to gamma irradiation. Both bisphenol A polycarbonate (PC) and PMMA can turn from ductile to brittle as shown in Figures 3a and 3b after the gamma irradiation, which is consistent with the evidence of chain scission after the gamma irradiation, shown in Figures 4a-b.

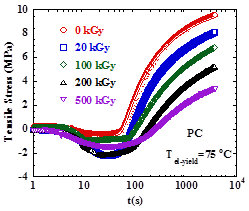

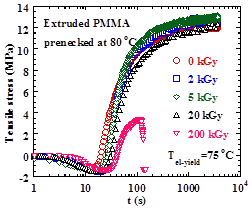

Cold-drawn polymer glasses show sizable retractive stress upon annealing. Figures 5 and 6 show that after the different dosages (1 Gy = 1 J/kg) of gamma irradiation the retractive stress level systematically drops. The effect of chain scission on this elastic yielding phenomenon suggests that the stress has a significant intrachain component. In other words, these results corroborate well the recent theoretical picture3 and underscores the importance to understand the role of chain networking in deformation of polymer glasses.

Figure 3 Engineering stress vs. draw ratio curves of (a) PC and (b) PMMA after gamma irradiation with different dosages at a crosshead speed of 6 mm/min at 23 and 80 oC respectively.

Figure 4 GPC determination of the change in the molecular weight of the gamma-irradiated (a) PC and (b) PMMA as a function of the dosage.

Figure 5 Retractive stress as a function of time at temperature Tel-yield = 75 oC of cold-drawn PC that received different dosages of gamma irradiation, where the cold-drawing was carried out to a draw ratio of L/L0 = 1.7.

Figure 6 Retractive stress as a function of time at temperature Tel-yield = 75 oC of cold-drawn PMMA that received different dosages of gamma irradiation, where the cold-drawing was carried out to a draw ratio of L/L0 = 2.2.

Table of Contents

Effects of molecular-weight reduction on brittle-ductile transition and elastic yielding due to non-invasive gamma irradiation on polymer glasses

[1] Y. Zhao, J. N. Liu, X. X. Li and S. Q. Wang, "How and why polymer glasses lose their ductility due to plasticizers", submitted to Macromolecules, 2016.

[2] P. P. Lin, et al., A. Joy and S. Q. Wang, "Effects of molecular-weight reduction on brittle-ductile transition and elastic yielding due to non-invasive gamma irradiation on polymer glasses", submitted to Macromolecules, 2016.

[3] S. Q. Wang and S. W. Cheng, "Experiments-inspired molecular modeling of yielding and failure of polymer glasses under large deformation", Chapter 12 in Polymer Glasses, ed. C. Roth, Taylor & Francis, 2016.

[4] S. W. Cheng and S. Q. Wang, "Elastic yielding in cold drawn polymer glasses well below the glass transition temperature", Phys. Rev. Lett. 110, 065506 (2013).

The above research strategy of utilizing gamma irradiation to induce chain scission was adopted as an alternative strategy to elucidate the molecular origins of mechanical stress. The proposed approach of photoirradiation of polymer glasses containing UV absorbing chromophores embedded in the polymer chains led to unexpected difficulties. Incorporation of alkoxyphenacyl chromophores into bis-phenol A polycarbonates gave polymers that were photodegradable, but the resulting polymers were brittle because of insufficiently high molecular weight and were not feasible for the current studies. We then incorporated alkoxyphenacyl chromophores in polylactides, which also gave photodegradable polyesters, but the polymer Tg was too low to enable the above studies to be carried out. Nonetheless, we will be shortly submitting the results of such chromophore incorporated lactides for publication as a demonstration of the influence on mechanical properties by incorporation of photoactive chromophores.