Reports: ND955845-ND9: Study of Clogging in Suspension Flows Using 2D Particulate Systems

Emilie Dressaire, PhD, New York University

During this first year of funding, my team and I have developed the experimental and numerical tools to study the aggregation and clogging processes in 2D suspension flows. We have observed the deposition of individual particles on an obstacle, compared the trajectories of the particles with numerical simulations and shown that the inertia of the particles can modify their capture at large enough particulate Reynolds number.

The research relies on an innovative model system in which buoyant particles float on top of a flowing liquid bath to study the aggregation and clogging mechanisms commonly observed in confined suspension flows. For colloidal particles, the formation of aggregates results from the competition between attractive surface interactions and hydrodynamic forces. Millimeter scale objects such as HDPE spheres locally deform the air/liquid interface, which results in attractive capillary interactions. Because the liquid bath is flowing in an open channel, drag forces are exerted on the floating particles. In vicinity of attractive fixed surfaces, one can therefore expect the formation of particle aggregates. These aggregates can grow until they span across the width of the channel forming a clog.

In the laboratory, a new experimental system has been developed to study the capture of advected floating particle by a fixed cylindrical obstacle. The particles are advected at the surface of an open channel flow. The channel is 30cm wide and 1 meter long. A porous medium placed at the inlet allows having a fairly short entry length, of the order of 20-30 cm. We can thus study the trajectory of the particles over 50-60cm. At the outlet, the liquid overflows a hydrophilic dam. The flow is driven by gravity to avoid the fluctuations that a pump would introduce. The flow rate is further controlled with a valve system. We have worked with Reynolds number from 10 to 100. The fixed obstacles are cylinders of diameter of the order of a few centimeters. We varied the material from hydrophilic to hydrophobic (copper, glass and nylon) to obtain a range of contact angles. The floating spheres are millimeter-sized and are made of nylon, polyethylene and teflon. By changing the composition of the sphere, we control the contact angle and density, which determine the sign of the water surface curvature. This curvature is related to the sign of the meniscus. Menisci of identical curvature (positive or negative) attract whereas menisci of different curvature repel. The set-up presented in Figure 1 includes covers so that the airflows in the room do not modify the particle trajectory. Note that the release mechanism has been automated to study the formation of aggregates. The system is controlled by Arduino and can release up to 40 particles autonomously. The position of release across the width of the channel can be programmed and be either determined by the user or generated randomly. The height of release of the particle is important too as it can modify the equilibrium curvature of the meniscus, depending on whether or not the particle crosses the surface.

Figure1: Experimental set-up

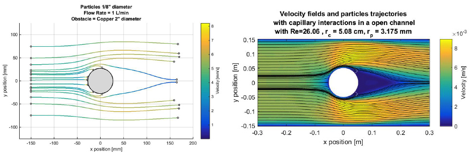

The experiments show that particles are indeed captured when the menisci on the cylinder (or obstacle) and the particles are identical. When the menisci are of opposite sign capture does not occur and particles are diverted away from the cylinder. The capture efficiency depends on the sizes of the menisci, the Reynolds number and the ratio of the particle to cylinder diameters. Some experimental results are presented in Figure 2 (left panel).

Numerically, we have developed a series of codes to (1) describe the flow in the channel, particularly in the vicinity of the obstacle and (2) define the trajectory of a particle released near the inlet. We use Comsol Multiphysics to describe the flow velocity in the channel. The inlet flow rate is imposed, and the flow is 3D and stationary. The trajectory of the particle is determined using a Basset Boussinesq Ossen (BBO) description. The velocity field obtained with Comsol is exported to Matlab where the BBO description is implemented. When a particle reaches a position that is close enough to the surface of the obstacle, typically when contact is made it is considered captured. The numerical simulations are in very good agreement with the experimental results (see Figure 2). However, the simulations cannot predict some of the inertial behavior that has been observed, such as particles bouncing off or rolling along the surface of the obstacle. Experiments show that inertial effects modify the equilibrium position of the particle on the surface of the cylinder.

Figure 2: Comparison of experimental (left) and numerical (right) trajectories.

At the end of the year, we started investigating the formation of aggregates at a fixed obstacle (Figure 3). The automation of the particle release has been instrumental to get statistical results. We are currently characterizing the size, and shape of the aggregate as well as the particle density. Depending on the maximum size of the aggregate, we will design constriction of comparable width.

Figure 3: Aggregate of HDPE particles (diameter:3.175 mm) on a copper cylinder.

These first results indicate that this simple two-dimensional system is sufficiently rich to capture the physics of aggregation and clogging mechanisms and sufficiently simple to allow theoretical and numerical characterization.

The students involved in the project have contributed to the results as follow:

- Emma Grimaldi: set-up and preliminary experiments.

- Federico Gregory: improvement of the set-up (including automation of particle release). Systematic experiments with single particles and preliminary aggregation experiments.

- Aymeric Debaisieux: numerical simulations.

- Saadman Chowdury and Kyle Casey: experimental study of the surface curvature as a function of the impact velocity of the floating particle.

As part of his Masters' thesis, Federico Gregori is currently working on a manuscript describing the single particle capture.

This funding as allowed the PI to develop a new area of research in the laboratory. Beyond this work on aggregation and clogging by floating particles, the PI is now working on the role of capillary effects on particle trapping in liquid films.