Reports: ND754633-ND7: Flow-Induced Organization of Bimodal-Sized Particles in Drying Polymer Droplets

Pinar Akcora, Stevens Institute of Technology

The unusual phenomenon of anisotropic assembly of particles during evaporation of polymer containing droplets was investigated throughout this project. In the first year, we studied the kinetics of contact-line movement under varying evaporation conditions and found that when the contact line dynamics is slowed down, micron-size particles deposit into concentric lines. While these rings are thought to be forming due to contact line pinning akin to coffee rings, the dynamics data we collected in fact revealed that particle deposition was controlled with the contact line velocity which was varied by the evaporation rates, and with the contact angle. The circulatory motion of particles seen in real-time videos in our system is driven by the Marangoni flows. In order to understand the assembly of nanoparticles in PVP solutions below overlapped concentration, it was essential to investigate the growth of aggregates (stripes) with time.

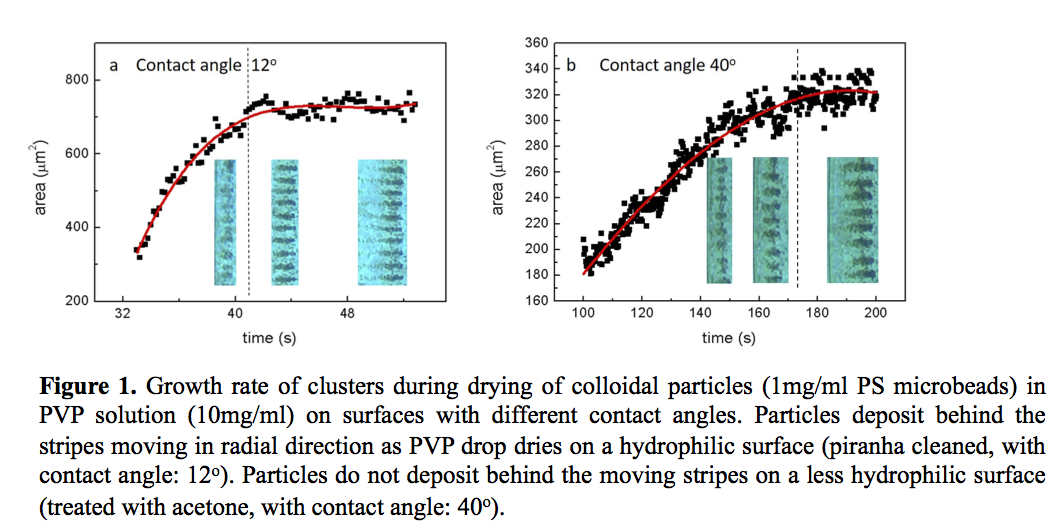

In the second year, we analyzed the optical microscopy videos of solutions drying on different surfaces with varying contact angles. We observed that the area of particle clusters grow initially (Figure 1) and distinctive stripes are formed when the internal shear flows due to phase separation of particles from polymers are balanced with the Marangoni flows. Figure 1 shows the dynamics of particles entering at a fixed area per time. The accumulation rate of particles increases linearly in the first 40s and the size of stripe domains almost remains constant when the competing forces of Marangoni and internal flows are balanced out and stabilized.

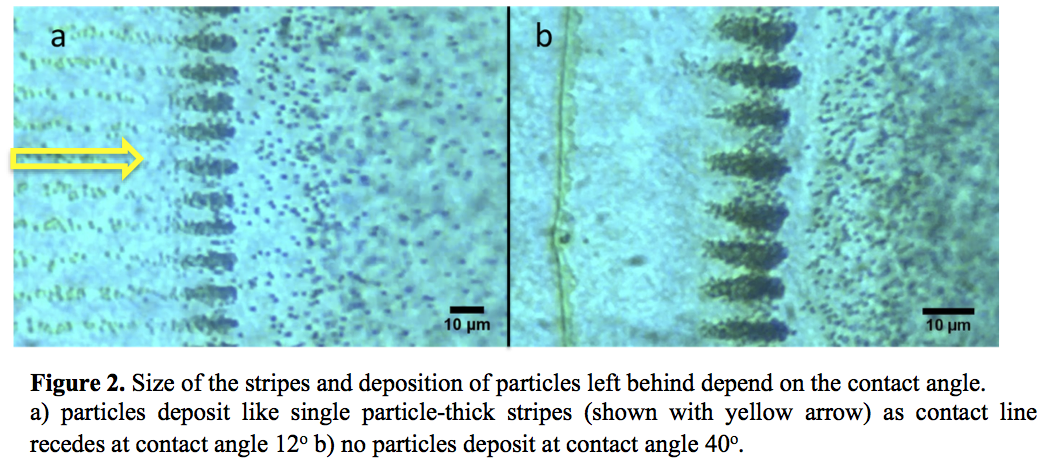

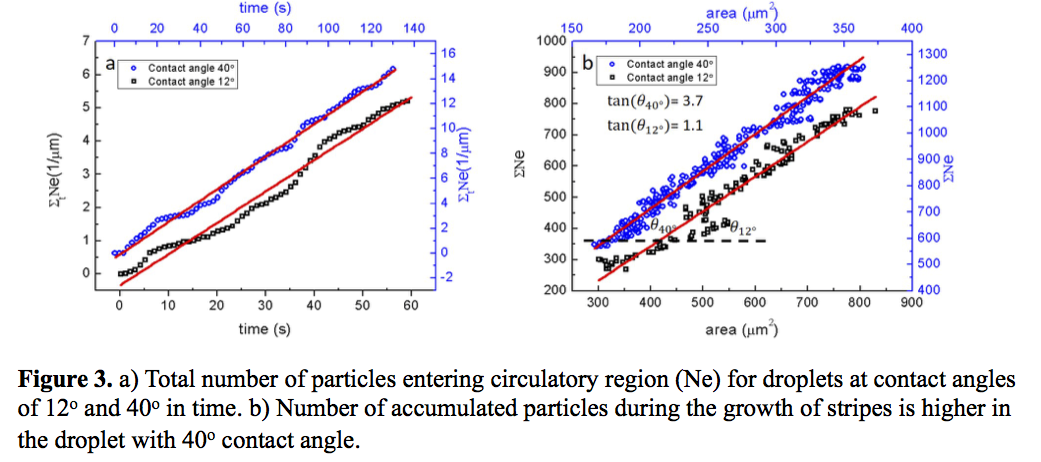

In an evaporating droplet, contact line pins for a short time and starts to recede. Particles circulate in the region close to the pinning line at a constant speed as shown in Figure 1. To maintain this stable size and shape of circulating region, some of the particles in circulating aggregates deposit once the maximum capacity is reached within the meniscus, which is easily achieved at small contact angles as shown in Figure 2a. The circulation area in the less hydrophilic surface can hold more particles and particles do not deposit as contact line recedes. For this reason, stripes are observed to be thinner at low contact angle (12o) and wider at high contact angle (40o) (Figure 2). Contact angle restricts the number of particles in circulatory region. Particle carrying capacity is found to be ~3 times larger when contact angle of colloidal droplet is 40o compared to the droplet with 12o contact angle (Figure 3).

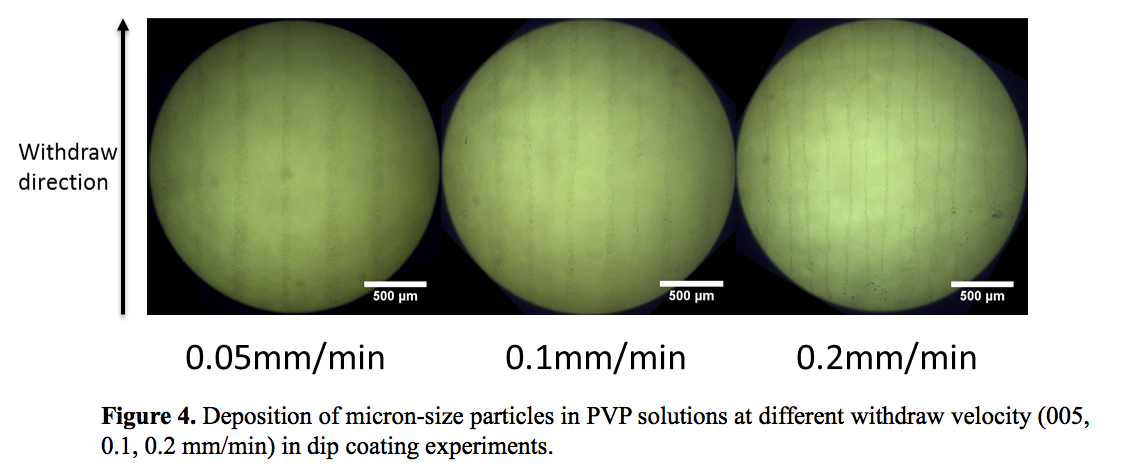

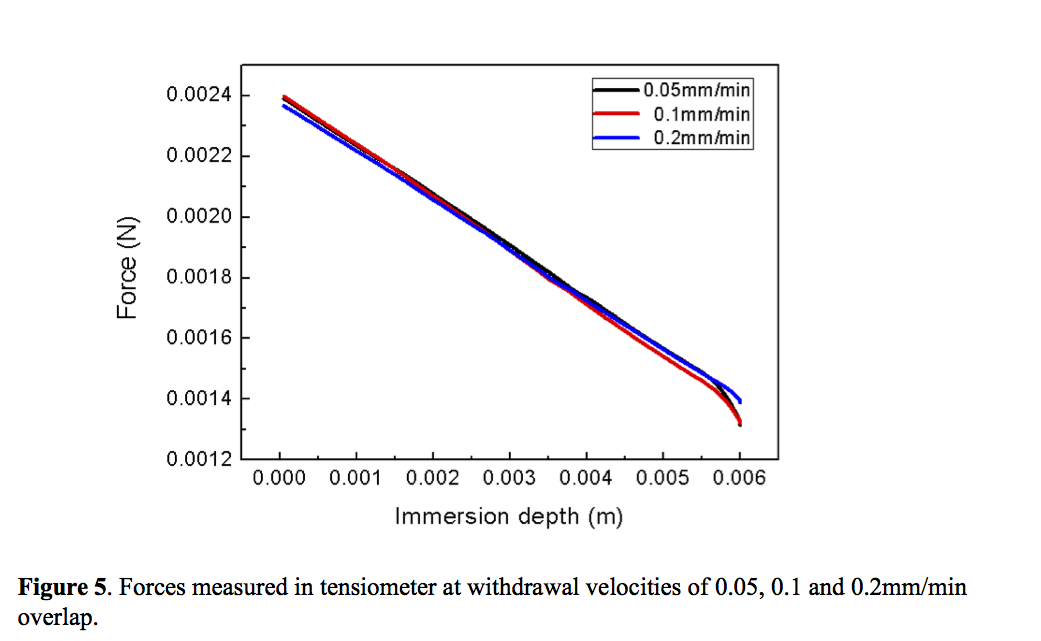

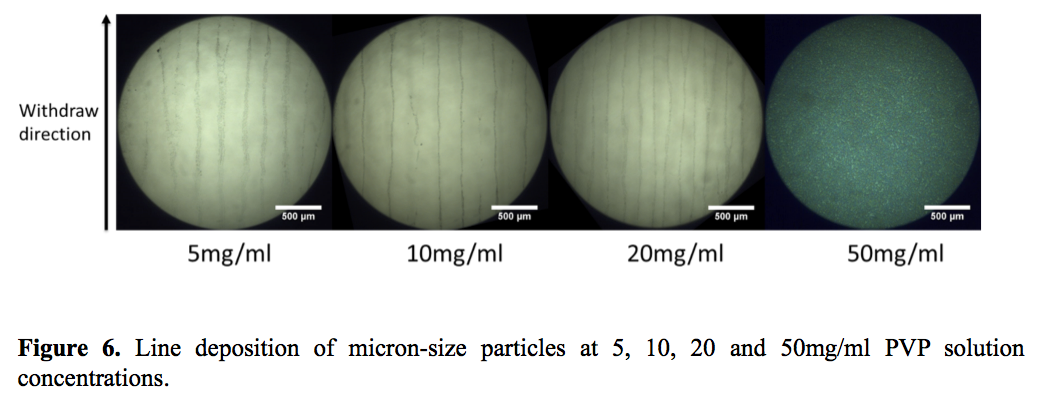

Dip coating is a commonly used technique to coat substrates with polymer or to deposit colloids in lines with the use of a stick-slip mechanism. Contrary to the many works in literature, our particles assemble parallel to the withdraw direction, which clearly shows that the colloidal assembly is not purely hydrodynamically driven. Additional internal convective flows from the phase separation of particles induce formation of continuous lines as the surface is pulled out vertically from the colloidal solution. Using the force tensiometer, we measured the tensile forces and calculated the contact angle of the static meniscus region. Figure 4 shows the depositions of particles on substrates withdrawn at different velocity. The slower the withdraw velocity, the more particles accumulate into circulatory region and form thicker lines. It is important to note this is not due to changes in contact angle. Figure 5 shows that contact angle does not change when measured at different velocities. In addition, distance between the continuous patterns is controlled with the polymer concentration. At high polymer concentrations, the polymer bridging of polymer chains is strong hence phase separation is stronger which subsequently affects the periodicity of lines (Figure 6).

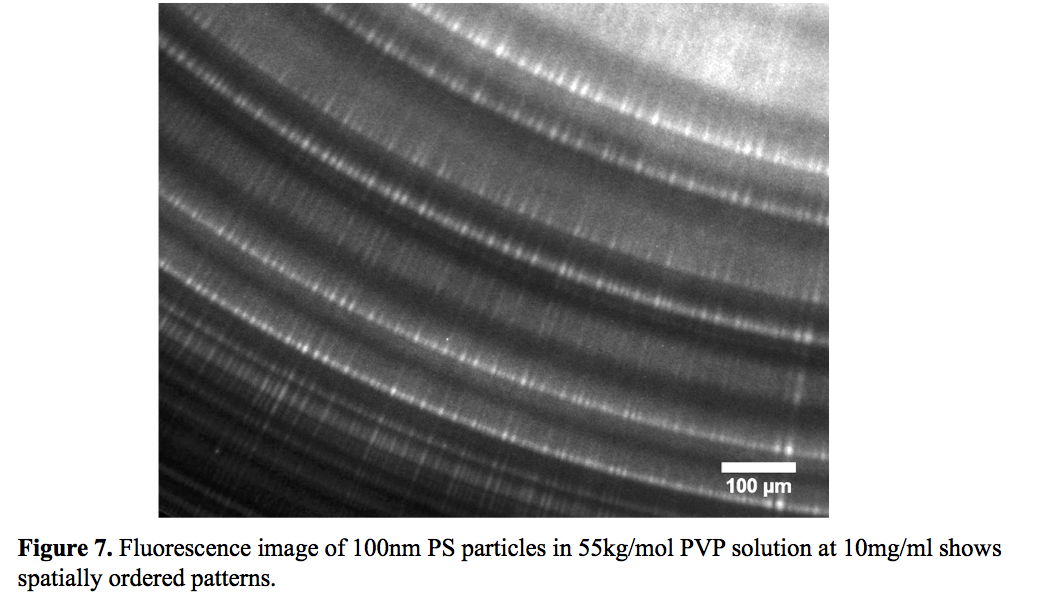

In summary, the deposition of colloidal particles into long lines are found to be due to balancing the convective forces from the spinodal decomposition of particles with the Marangoni flows. By varying the polymer concentration and chain length, we were able to show that width and periodicity of lines can be tuned in dip coating process. We reported the dynamics of contact line and aggregation mechanism using optical microscope, goniometer and tensiometer. Dynamics of contact line, contact angle and in-situ imaging of particles were measured to understand the assembly of colloids in polymer solutions. We observed the similar phenomenon with 100nm PS nanoparticles (Figure 7).

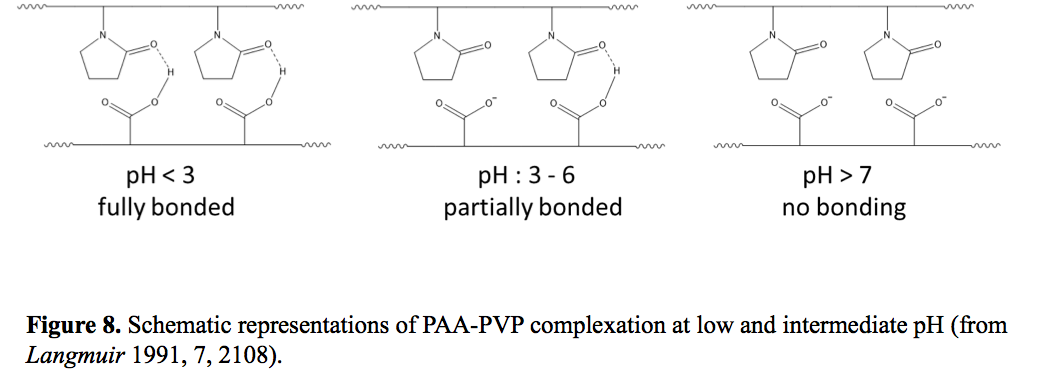

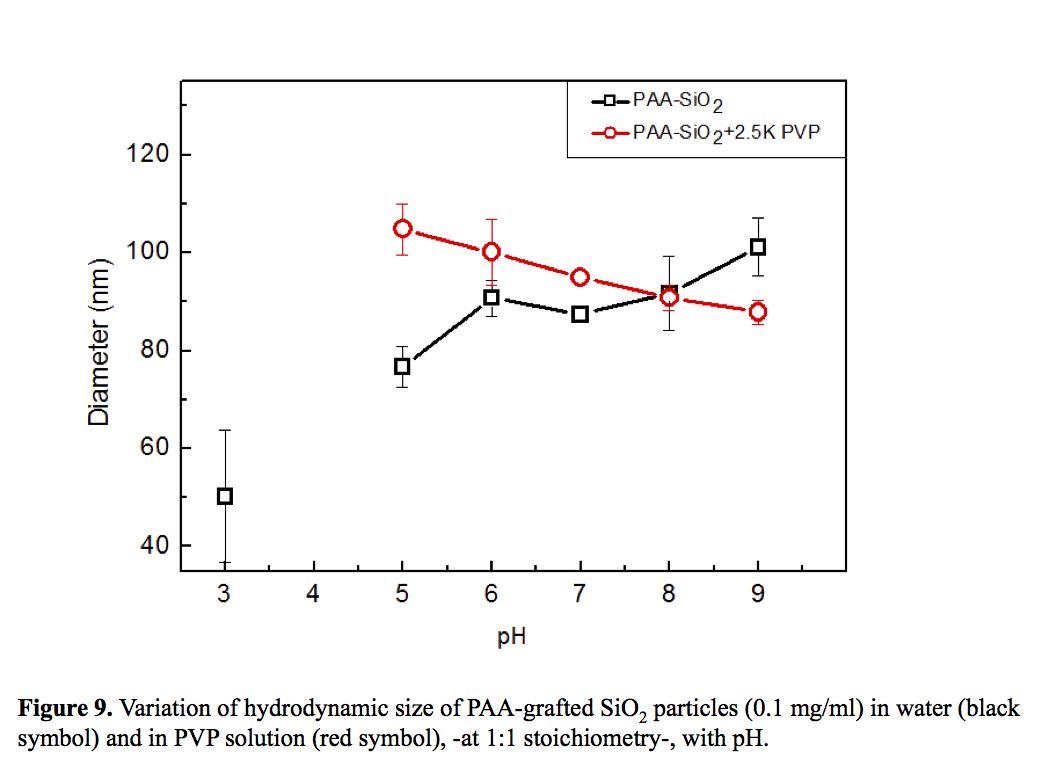

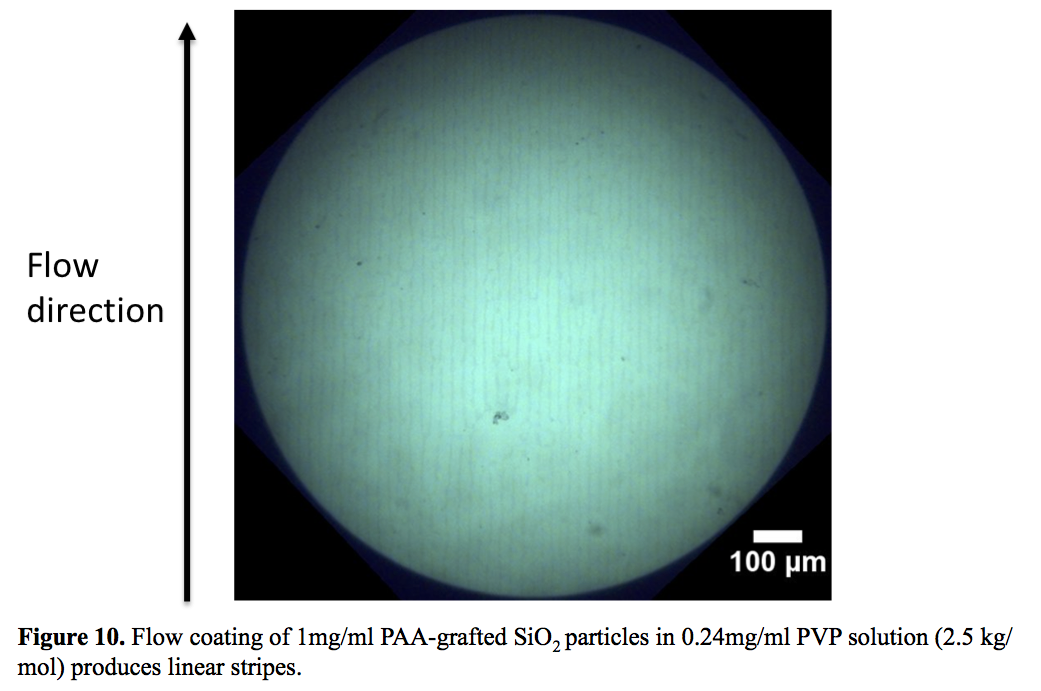

To study interactions between free chains and particles, PAA-grafted 50nm SiO2 particles were prepared. PAA (300 kg/mol)-grafted SiO2 was synthesized by surface initiated ATRP of tert-butyl acrylate to form PtBA-SiO2 and then hydrolyzed by trifluoroacetic acid. Grafting density was measured 0.01chains/nm2 from TGA measurements. PVP and PAA are known to form hydrogen bonding at pH lower than 3 (Figure 8). They are partially bonded between pH 3-6. We know that hydrodynamic size of PAA-grafted SiO2 in water should increase when pH is changed from 3 to 6 because of the ionization of –COOH (Figure 9). In PVP, swelling of PAA chains is suppressed due to hydrogen bonding between two polymers, thus particle size decreases with pH. At pH 11, there is no hydrogen bonding between PAA and PVP, thus solubility of particles increases and contact line does not pin. Continuous and highly ordered grafted nanoparticles are obtained in dip coating at high pH 11 (Figure 10). With this system, we show the role of strong attraction of free chains to the particles on the evaporation-induced assembly. These results are discussed in two journal papers which we currently prepare for publication. The grant helped us to develop a strategy of ordering colloids and nanoparticles with physical bridging of polymers or hydrogen bonding between different polymers using dip coating process. This strategy can be applied to graphene and other functional particles for devices requiring ordered particle arrays.

Impact on Students: A Ph.D. student (Chongfeng Zhang) is being supported with this grant. Chongfeng passed his PhD oral qualifying exam and presented his research results at the 251st ACS National Meeting in San Diego, March 16, 2016 and at the 12th National Graduate Research Polymer Conference at the University of Akron, OH, June 19-22, 2016.