Reports: ND653930-ND6: Multifunctional Desulfurization Elastomeric Polymer Nanocomposites

Zhanhu Guo, University of Tennessee

Suying Wei, Lamar University

This project targeted both preparation of unique multifunctional substrate-supported elastomeric polymer nanocomposite membranes (PNMs) and their application in desulfurization treatment using thiophene/hexadecane mixture as a model fuel. The major goals of this project were to prepare PNMs with enhanced mechanical property, followed by the performance test in removing sulfur compounds from model fuel. We explored various potential substrate systems during the past year regarding their porosity, functionality, crystallinity, and viscoelastic properties, among others, as these are the parameters that affect the performance of the supporting substrate in the pervaporation process. The investigated substrate systems include PANI/TiO2, PANI/CF, PP/CNT, CNT/ethylene/1-octene copolymers and PP/iron oxide. The detailed knowledge revealed from the studies were summarized below:

1. Titania/polyaniline nanocomposite system

The polyaniline (PANI) nanocomposite was prepared by a surface initiated polymerization (SIP) method. The titania nanoparticles have been successfully embedded in the conductive PANI matrix by the morphology study via scanning electron microscopy (SEM) and high resolution transmission electron microscopy (HRTEM). The X-ray diffraction (XRD) results indicated that TiO2 exerted a significant influence on the crystalline structure of PANI. The optical properties of TiO2/PANI nanocomposites indicated that the adding of TiO2 nanoparticles into the PANI matrix has little effect on the Egopt of PANI.

Fig.1 UV-vis DRS of (a) pure PANI and TiO2/PANI nanocomposites with a TiO2 nanoparticle loading of (b) 2.0, (c) 5.0 and (d) 10.0 wt%; the inset of UV-vis absorption edge (λedge) of pure PANI.

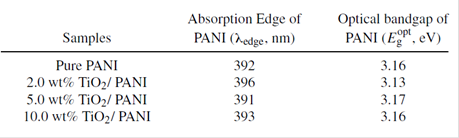

Table 1. Absorption edge and optical bandgap of pure PANI and PANI/TiO2 with various TiO2 loading.

2. Incorporation of polyaniline with carboxylated carbon fabric

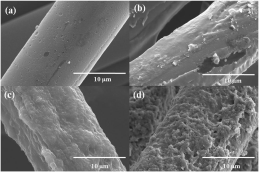

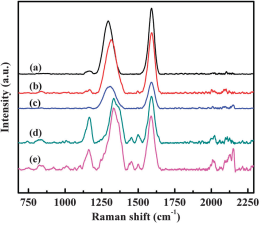

Carbon fabric was successfully oxidized by nitric acid, and the carboxylic acid facilitated the incorporation of polyaniline. SEM images and Raman spectra revealed the changes in both morphological structure and surface functionalities. Furthermore, the structural difference in the vertical and diagonal directions of the carbon fabrics contributed to the varied properties of the composite. The composite was much rougher (SEM) and disordered (Raman) compared to the as received carbon fabric, and increased pore size with increasing PANI loading.

Fig. 2 SEM images of (a) CFs and PANI–CFs with a PANI

Loading of (b) 5.0, (c) 15.0 and (d) 30.0 wt%.

Fig. 3 Raman spectra of the (a) as-received CFs, (b) HNO3 treated CFs, and

the PANI–CFs with (c) 5.0, (d) 15.0 and (e) 30.0 wt% PANI loading.

3. PP at low CNT loading levels

The CNTs coated on the surface of gelated/swollen soft PP powders were easily pressed together and formed a network structure in the hosting materials, which led to the outstanding electrical properties. At lower pressing temperature (120 °C), CNTs formed network easily than at higher temperature (180 °C). Meanwhile, the CNTs were observed to favor the formation of γ-phase PP. The CNTs served as nucleating sites to promote crystallization of PP at the lower loading (0.1 wt %). CNTs also served as the branches of polymer chains to enhance the disentanglement of polymer chains and caused a decreased viscosity of PNCs even lower than that of pure PP. For the PP/CNTs system, the lower band gap of CNTs was associated with the stronger deformation of polymer matrix at elevated processing temperatures. Scheme 1 illustrated the proposed mechanism of CNTs in reducing the viscosity of nanocomposites.

Fig. 4 Conductivity of PP/CNT nanocomposites as a function of CNT loading level. At lower processing temperature (120 °C), CNTs formed network easily than at higher temperature (180 °C).

Scheme 1. Nanoparticles Act as Branches of the PP Polymer Chain

Leading to an Extensional Force on the Backbone.

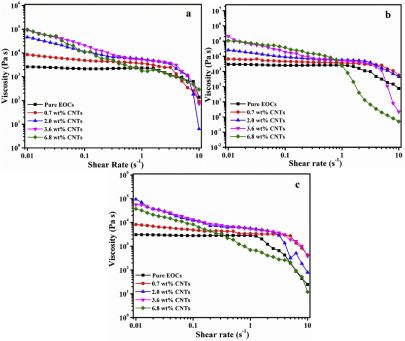

4. CNTs in ethylene/1-octene copolymers

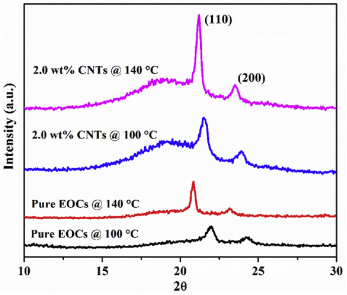

High electrical conductivity in ethylene/1-octene copolymers (EOCs) was achieved by sticking CNTs onto the gelated EOCs pellet surface and the subsequent hot pressing. From Figure 5, it shows that there is mainly a strong reflection peak followed by a weaker peak, ascribing to the typical orthorhombic unit structure of the (110) and (200) reflection planes. The peak minimum positions of the (110) and (200) are detected at 20.8° and 23.1° for pure EOCs processed at 140 °C, which shift to lower angles compared with that of EOCs processed at 100 °C. It can also be observed from that of 2.0 wt% nanotube PNCs pressed at 100 and 140 °C. Neat EOCs and their nanocomposites exhibited both Newtonian and shear thinning behaviors under melting state. Less internal chain-chain friction heat was generated than that of neat EOCs after applying the same oscillation frequencies.

Fig. 5 XRD curves of EOCs processed at 100 and 140 °C, and the 2.0 wt% CNT nanocomposites

made at 100 and 140 °C.

Fig. 6 Angular frequency (u) dependent (a) Storage modulus (Gʹ), (b) loss modulus (Gʹʹ), and (c) loss factor (tand) of neat EOCs and EOCs/CNTs nanocomposites melts (measured at 170 °C) with different CNTs loadings processed at 140 °C.

5. PP/Iron oxide

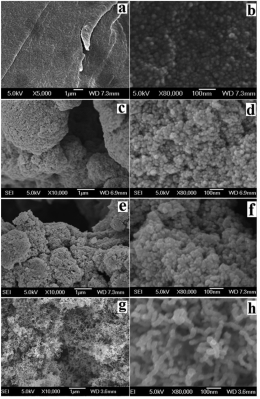

Thermoplastic polymer PP was incorporated with Fe2O3 NPs by a simple thermal treatment method. The NPs have controllable sizes, crystalline structures, assembly patterns and magnetic properties with the aid of commercially available PP-g-MA. The coordination strength by PP-g-MA controls the surface oxygen vacancy/defect, nuclei density, and defect distortion induced stacking sequence rearrangement: stronger coordination strength (from higher PP-g-MA%) favors to form thermo-dynamically stable α-Fe2O3 and the lower PP-g-MA% tends to lead to the less stable γ-Fe2O3 NPs.

Fig. 7 SEM images of Fe2O3 NPs formed via thermo-decomposing Fe(CO)5 in (a, b) 1.0 g; (c, d) 0.5,

(e, f) 0.25, and (g, h) 0.125 g PP-g-MA in 100 mL xylene.

In summary, various substrate polymer systems have been investigated and the following work will be pursued to test the desulfurization performance and the results will be used to guide further optimization of the membrane preparation.

a) The elastomeric composite membrane supported on the substrate polymer systems will be applied to the pervaporation process;

b) Model gasoline such as thiophene/hexadecane will be used to study the separation performances.