Reports: UNI555263-UNI5: Studying Weathering Effects at Interfaces Within Wood-Polymer Composites Using Imaging Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS)

Robyn E. Goacher, PhD, Niagara University

Background

Wood Polymer Composites (WPCs) are a promising material with improved properties over wood or plastic alone. WPCs are common in outdoor applications such as decking and in automotive panels. They allow for the recycling of plastics and reclaimed wood, resulting in the promotion of WPCs as environmentally friendly. WPCs are, however, relatively new materials and current product development research targets increased WPC strength along with many other features: the addition of anti-microbial and anti-fungal properties; and increased resistance to fire, moisture absorption, thermal expansion and degradation due to UV light.

It is important to understand the interface of the hydrophilic wood and hydrophobic thermoplastics used in WPCs, and any migration, blooming or diffusion effects caused by weathering. In this research, we aimed to expand this understanding by using Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS), which is a surface sensitive mass spectrometry technique with high spatial resolution. Prior to receipt of ACS PRF funding, our preliminary results indicated that ToF-SIMS was able to distinguish between weathered and unweathered WPCs, and to identify changes in the spatial distribution of different chemical signals.

The goals of the first year of grant funding were to: 1) examine the role of surface contamination on the ToF-SIMS results and develop an appropriate WPC cleaning method, and 2) explore the broader applicability of ToF-SIMS analysis to WPCs created from different polymers.

Developing a Cleaning Method for WPCs

Due to the surface sensitivity of ToF-SIMS, contamination of the sample due to handling can confound understanding of the underlying WPC chemistry. Contamination of WPCs is expected to arise from lubricants used during extrusion (often these are fatty acids and their salts) and from fingerprints. Any cleaning method used should minimize the presence of these contaminants, while not significantly altering or degrading the native composition of the underlying wood and polymer.

To explore cleaning approaches, a commercial WPC material was obtained from a hardware center and was sectioned to obtain pieces from the surface and interior. Interior samples were considered as controls. Assuming no component segregation during manufacture, a successful cleaning method would produce spectra of the WPC surface that more closely matched the WPC interior.

Cleaning was evaluated by soaking and rinsing with water and/or isopropanol. The ToF-SIMS spectra of uncleaned and cleaned interior and surface samples were analyzed with Principal Component Analysis (PCA) (data not shown). The as-received surface and interior samples were clearly distinguished due to surface contaminants. Soaking in water was determined to be the best method for WPC cleaning because the spectra of surface samples soaked in water were similar to the as-received interior samples and to interior samples soaked in water. Thus, the surface contaminants were removed, and the water-soaking did not significantly alter the interior controls. Isopropanol effected only partial contaminant removal, and rinsing alone was inadequate compared to soaking. A 4-hr water soak was determined to be optimal, and this treatment was also found to be effective in removing fingerprint contamination from deliberate handling.

Distinguishing Different WPCs

The work was expanded from the analysis of a single commercial brand of WPC to include the analysis of research-grade WPCs made from nylon, styrene maleic anhydride (SMA), or polypropylene (PP) of different origins and colors. Multivariate Curve Resolution (MCR) was used to process the ToF-SIMS spectra of these samples (Figure 1). The first calculated component described surface samples (which scored positive, Fig 1A) due to salts (23u=Na+, 39u=K+) and small hydrocarbons (Fig 1 B). The different polymers used were clearly identified with components containing peaks characteristic of nylon (Fig 1 C-D), SMA (Fig 1 E-F), polypropylene (Fig 1 G-H) and wood (Fig 1 I-J), where the interiors were wood-rich due to exposure of wood grains during cutting. These results compared well with visual microscopy and SEM analysis, as illustrated in the table of contents image.

Figure 1: MCR scores (A, C, E, G, I) and corresponding loadings (B, D, F, H, J) showing components identified among positive ToF-SIMS spectra from five as-received WPC samples.

Ongoing and Future Work

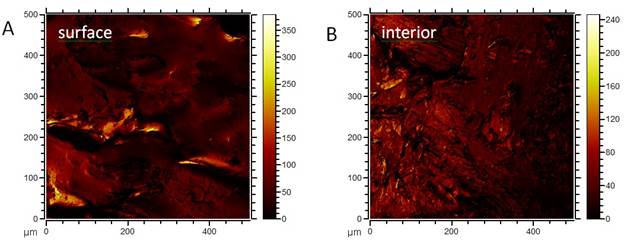

Ongoing and future work will focus on the examination of ToF-SIMS chemical images of the WPC samples. Our first image analyses on our new WPCs were performed with a rapid mode with ~5µm spatial resolution, an example of which appears in Figure 2 for nylon and SMA WPCs. The surfaces scored positive (red and yellow, bottom row in Fig 2A) and showed islands corresponding to salts and polymer (40 and 113u) in the positive loadings (Fig 2B). Interiors scored negative (dark blue, top row in Fig 2A) corresponding to other polymer peaks at 71, 91, 128, 165, 202, and 239u (Fig 2B). Chemical images may be obtained with higher resolution on the order of 100s of nanometers (Figure 3) and future work will include processing the chemical differences at higher resolution to look for smaller features.

Additional future work will explore the effects of natural outdoor weathering on the chemicals present in the WPCs and their distributions. The strengths and weaknesses of ToF-SIMS for these measurements will also be clarified by comparing with more complementary instrumental techniques.

Figure 2: PCA scores images (A) and loadings (B) for low-resolution ToF-SIMS images of as-received Nylon and SMA interior and surface samples. Field of view of 500x500 µm2 per image.

Figure 3: High-resolution ToF-SIMS total ion images of a polypropylene WPC’s surface (A) and interior (B). Field of view of 500x500 µm2. Color scale is maximum counts per pixel.

Impact on Students and PI

Five undergraduate students participated in the design and execution of this project, gaining advanced instrument and data analysis experience. Students gained individual and teamwork skills, and presented their results at regional and national conferences, including the national ACS meeting. The grant has substantially furthered the progress of this project in our lab group, including through the start of a new collaboration with an engineering research group that can create research-grade WPCs.