Reports: ND955700-ND9: Electrohydrodynamic Atomization of Fuels Using Charge-Injection for Efficient Flameless Catalytic Combustion at Small Scale

Paul R. Chiarot, PhD, State University of New York at Binghamton

Project Summary

Flameless catalytic combustion of petroleum-based fuels inside miniaturized systems is a new paradigm in portable power generation. The most promising fuels for portable applications are those with the highest energy density. However, these fuels are often the most difficult to vaporize and mix with the oxidant. We are exploring the use of electrohydrodynamic (EHD) atomization to vaporize and mix energy dense, liquid fuels. We seek to achieve efficient atomization without the need for fuel additives and to use secondary electric fields to shape the emitted droplet plume to enhance combustion performance.

Research Progress and Results

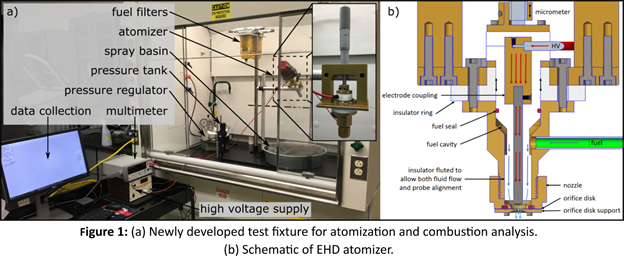

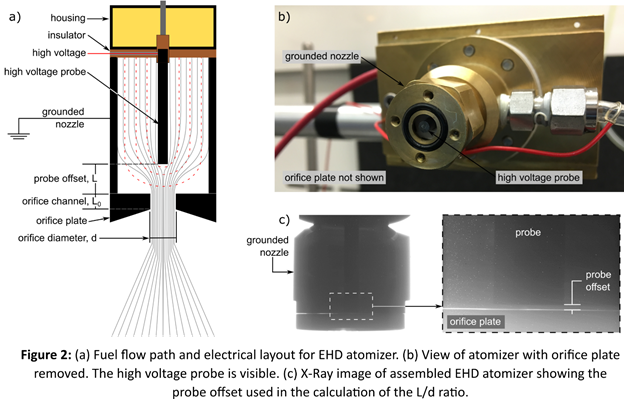

The first-generation of the EHD atomizer was designed to be customizable so that the key atomization parameters could be easily modified (Figure 1). In particular, the atomizer was designed to allow for changes in the orifice diameter and position of the integrated high-voltage probe electrode. Variation of these two parameters allows for control over the L/d ratio, which is the ratio of the probe electrode offset to the orifice diameter (Figure 2). Our preliminary results show that this ratio plays a key role in atomization. To obtain a precise measure of the L/d ratio, X-Ray images of the probe offset were obtained for the assembled atomizer (Figure 2c). Our proposed second-generation atomizer will be more compact and built using the optimized geometry. The first-generation concept was manufactured through a new collaboration with Progressive Tool in New York, who generously donated in-kind support to machine three of the most complicated atomizer parts. We also acknowledge Spray Systems Co. (Chicago) and Professor John Shrimpton (University of Southampton) for their assistance on the design and operation of the EHD atomizer. Along with building a preliminary concept for the atomizer, we designed a novel fixture to facilitate spray and combustion testing (Figure 1). The completed fixture incorporates hardware for positioning the atomizer, a high voltage source, high-speed digital imaging, thermocouples to monitor burner temperature, and an exhaust gas analyzer.

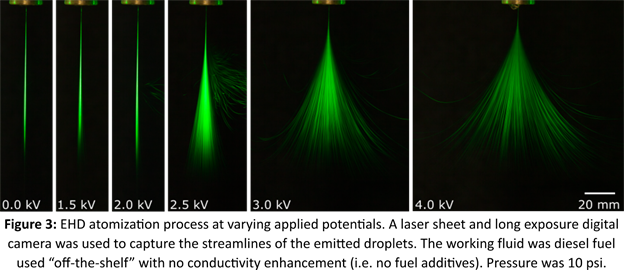

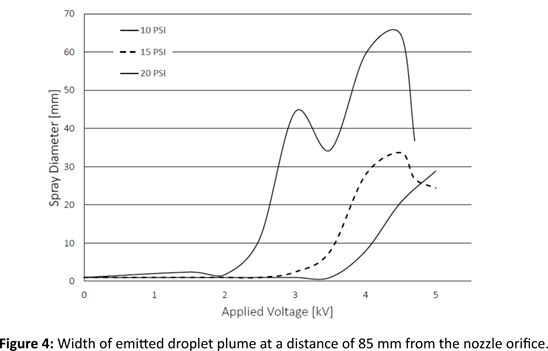

We used the first-generation EHD atomizer and fixture to test our hypothesis that electric charge injection can be used to atomize energy dense fuels without the need for conductivity enhancers (i.e. fuel additives). Figure 3 show the atomization process for varying electric potentials. The working fluid was diesel fuel that was used as supplied by the vendor (i.e. “off-the-shelf” with no conductivity enhancers). These images were captured using a laser sheet and long exposure digital camera. Therefore, the streamlines of the emitted droplets were recorded. This experiment supports our hypothesis that charge injection can be used to achieve atomization without the need for fuel additives. Atomization is first initiated at ~2 kV and remains stable at probe voltages up to 5 kV. Beyond this voltage, breakdown occurs inside the atomizer, and atomization stops. At 4 kV, the droplet plume spans several 10s of millimeters. The width of the plume highlights the need for secondary electric fields to constrain the droplets for combustion in a microenvironment (as per our second hypothesis). To quantify the width of the plume, we measured its dimensions 85 mm from the orifice (Figure 4). The rapid increase in the plume width with increasing applied potential reveals that the charge injection process is highly non-linear. Measurements of plume geometry also assists in designing the secondary electric field to constrain the plume.

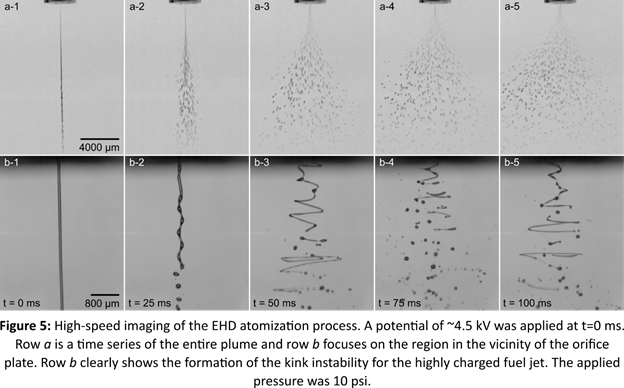

To compliment the streamline images shown in Figure 3, high-speed imaging of the emitted droplets was conducted to create new knowledge of the atomization process. In Figure 5, a time sequence of the atomization from t=0 ms (when the high-voltage is activated) to t=100 ms is shown for an applied potential of 4.5 kV. Row a images the entire plume and row b focuses on the jet region in the vicinity of the orifice. We found that the plume rapidly assumes its final shape only ~75 ms after the potential is applied. The high droplet charging ensures the droplets remain uniformly distributed within the plume and their size is highly polydisperse. However, most striking is the formation of the whipping (kink) instability of the highly charged fuel jet as it exits the orifice (Figure 5, row b). Our results reveal that this instability dominates the atomization process and governs the size of the emitted droplets.

Impact of this Research

The combustion of petroleum-based fuels inside miniaturized systems will have a major impact on portable power generation. The energy output from these systems has the potential to far exceed advanced lithium ion battery technology. Direct conversion of heat into electrical energy is possible using a new class of modern thermoelectric materials. The most promising fuels for portable applications are those with the highest energy density. However, these fuels are often the most difficult to vaporize and mix with the oxidant. Incomplete vaporization leads to poor combustion performance and the production of hazardous reaction products. This is especially a problem for miniaturized systems given the limited size of the combustion chamber. This research is creating new knowledge on the EHD atomization of fuels to address these issues. Applying this new knowledge will support the creation of a new, compact energy source based on the use of readily available fuels.

This project provides financial support for a PhD student and an undergraduate student in Mechanical Engineering at SUNY Binghamton. The highly interdisciplinary nature of this project - combining fluid mechanics, heat transfer, chemistry, and combustion engineering – is an excellent educational opportunity for these students. This research is preparing them for a future career focused on new technologies related to combustion.

Research Plan for Project Year 2

In Year 2, our objective is to test our second proposed hypothesis: that external electric fields can be used to confine the droplet plume to the center of the micro reactor (via the Coulombic force) while still maintaining good separation between droplets. Using the new knowledge created in Year 1 of this project, we will optimize the atomization process to produce small droplets (for rapid evaporation) with low charge (for small velocities) to enhance combustion performance in a microenvironment.