Reports: DNI1054886-DNI10: Design and Characterization of Hydrogel-Based Internal Curing Agents for Oil Well Cementing Applications

Kendra A. Erk, PhD, Purdue University

Motivation and Objective: Many recent oil production disruptions are not due to the drilling or extraction process itself but instead are due to cement failure, often related to improper curing of cement oil well linings or plugs. In structural concrete applications, water-filled hydrogel-based internal curing (IC) agents are mixed into the cement paste to ensure proper hydration during curing, leading to a corresponding increase in compressive strength and durability of the final product. To extend this beneficial technology to oil well cementing applications, there is a critical need to design a new class of hydrogel-based IC agents. To address this need, the scientific objective of this research project is to identify the fundamental material structure-property-performance relationships of model polymeric hydrogels and hydrogel-cement mixtures exposed to the elevated temperatures, pressures, and ionic activity common to downhole environments. Through this work, the swelling and mechanical response of custom-synthesized superabsorbent polymer (SAP) hydrogel particles can be related to the chemical and physical macromolecular structure, the early-age hydrogel-cement mixture properties (including workability, degree of hydration, and shrinkage), and the compressive strength and microstructure of the final cured product. By developing IC agents specifically designed for oil well cementing, the risk of cement-failure due to improper curing will be significantly reduced and potentially eliminated, increasing the success and safety of oil production.

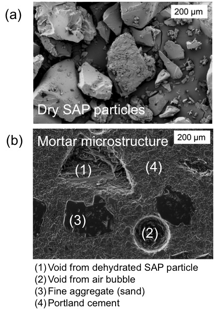

Significant Results: Acrylic-based SAP hydrogel particles were created from solution polymerization of various ratios of acrylic acid and acrylamide monomer with methylenebisacrylamide utilized as a chemical crosslinking agent. The reaction product was crushed and ground, to yield irregularly shaped dry particles with a range of sizes (see Fig. 1a). As IC agents, the SAP particles are incorporated into concrete mixtures in the dry state; the particles then absorb some of the free water in the mixture and swell to many times their initial dimensions. Following mixture placement, the particles will then release their stored water over time as the cement hydration reaction proceeds and water is consumed. The extra water released from the particles prevents self-desiccation of the mixture, which in turn reduces volumetric shrinkage and the formation of cracks. Following dehydration of the SAP particles, voids remain in the microstructure of the hardened concrete (see Fig. 1b), which have been found to beneficially increase the freeze-thaw resistance of concrete in cold-weather environments.

Figure 1: SEM micrographs of (a) dry SAP particles and (b) hardened microstructure of SAP-containing mortar illustrating the voids that remain once the SAP particles are fully dehydrated.

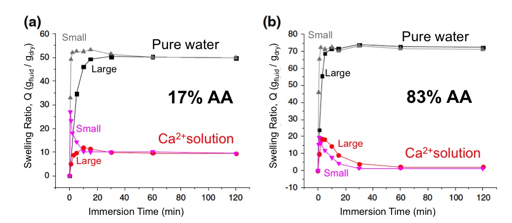

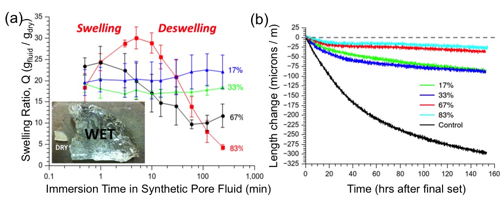

It was recently discovered that the SAP particles absorption and desorption performance (and thus its internal curing effectiveness) is strongly sensitive to the presence of cations in the water, including K+, Na+ and Ca2+, which are naturally present in cementitious mixtures as by-products of the hydration reaction. As shown in Fig. 2, the equilibrium (long-time) fluid absorption capacity was significantly reduced when SAP particles were immersed in aqueous solutions containing calcium, with the greatest reductions observed for particles containing the highest concentration of acrylic acid (AA) segments in their chemical structure (which will deprotonate and adopt a negative charge at pH > 5). Additionally, the size of the SAP particles was found to impact absorption kinetics, with smaller particles able to absorb fluid more rapidly than larger particles. Furthermore, when SAP particles are immersed in alkaline solutions designed to mimic cement pore fluid (see Fig. 3a), rapid fluid absorption followed by desorption was observed for particles containing the highest concentration of AA segments. Interestingly, while this fast desorption behavior was initially believed to be undesirable for internal curing, mortar containing these high-AA hydrogel particles displayed the lowest amount of shrinkage over a 7-day period (Fig. 3b) and would thus be expected to display less shrinkage-related cracking and an increased overall service life.

Figure 2: The swelling behavior of two different SAP particles sizes (classified size ranges as small = 100-400 micron; large = 400-800 micron) of poly(acrylic acid (AA)-acrylamide) hydrogels containing (a) 17% AA and (b) 83% AA immersed in pure water and 0.025 M calcium nitrate solutions.

Figure 3: (a) Swelling behavior of SAP hydrogel particles containing 17 to 83% AA during immersion in model cement pore fluid; (b) autogenous shrinkage of mortars containing same hydrogel particles at a dosage of 0.2 % by wt. of cement. Inset of (a) shows the swelling of a dry 0.5 cm particle following immersion in pure water.

Dissemination and Impact: The results from this research project have been disseminated through peer-reviewed publications and conference presentations at national meetings of the American Chemical Society, the American Concrete Institute, and the American Ceramics Society. Though in its early stages, this project is already having a significant impact on the concrete materials community, by clearly demonstrating that organic chemical additives (including hydrogel-based IC agents and other admixtures) can have a significant chemical and physical impact on the final properties and performance of cementitious materials. Additionally, with support from the ACS Petroleum Research Fund in the early stages of Prof. Erks tenure at Purdue, her research efforts now effectively apply fundamental knowledge of hydrogel chemistry, mechanics and rheology to tackle real-world technical challenges in the engineering community related to the structural and energy infrastructure of the nation, including the performance of concrete used in buildings, pavements, and oil wells. The materials engineering graduate and undergraduate students involved in this research project have had deep exposure to the science and engineering related to concrete materials and the petroleum exploration and recovery progress. Coupled with the fundamental chemistry and physics curriculum at the root of materials engineering, these students are now well-equipped to make significant contributions to the building materials and petroleum exploration communities following graduation. Ultimately, the successful completion of this research project is expected to have a significant positive impact upon advancing the foundational mission of the ACS Petroleum Research Fund of strengthening the petroleum field through scientific exploration.