Reports: DNI1055625-DNI10: Targeting Earth-Abundant Superhard Materials via Informatics and Optimized Chemical Bonding

Jakoah Brgoch, PhD, University of Houston

The prior year’s research efforts focused on two major research areas by employing computation in tandem with experiment to develop novel superhard materials. Specifically, this project used data-mining to establish the metrics most related to a materials mechanical properties, which is now being used to screen vast databases of compounds. The project has expanded to also include more advanced statistical data-mining methods such as partial lease squares analysis (PLS) to predict new, previously unexplored phases.

The first research results in this project showed it is possible to capitalize on computational informatics to predict mechanical properties and augment experimental information. Combining these two traditionally distinct focuses will allow researchers to predict complex mechanical response like hardness while targeting only the ideal composition space. This work compiled a large database containing the crystallographic information and mechanical properties to show that there are definitive correlations between structural and compositional characteristics and the mechanical properties.

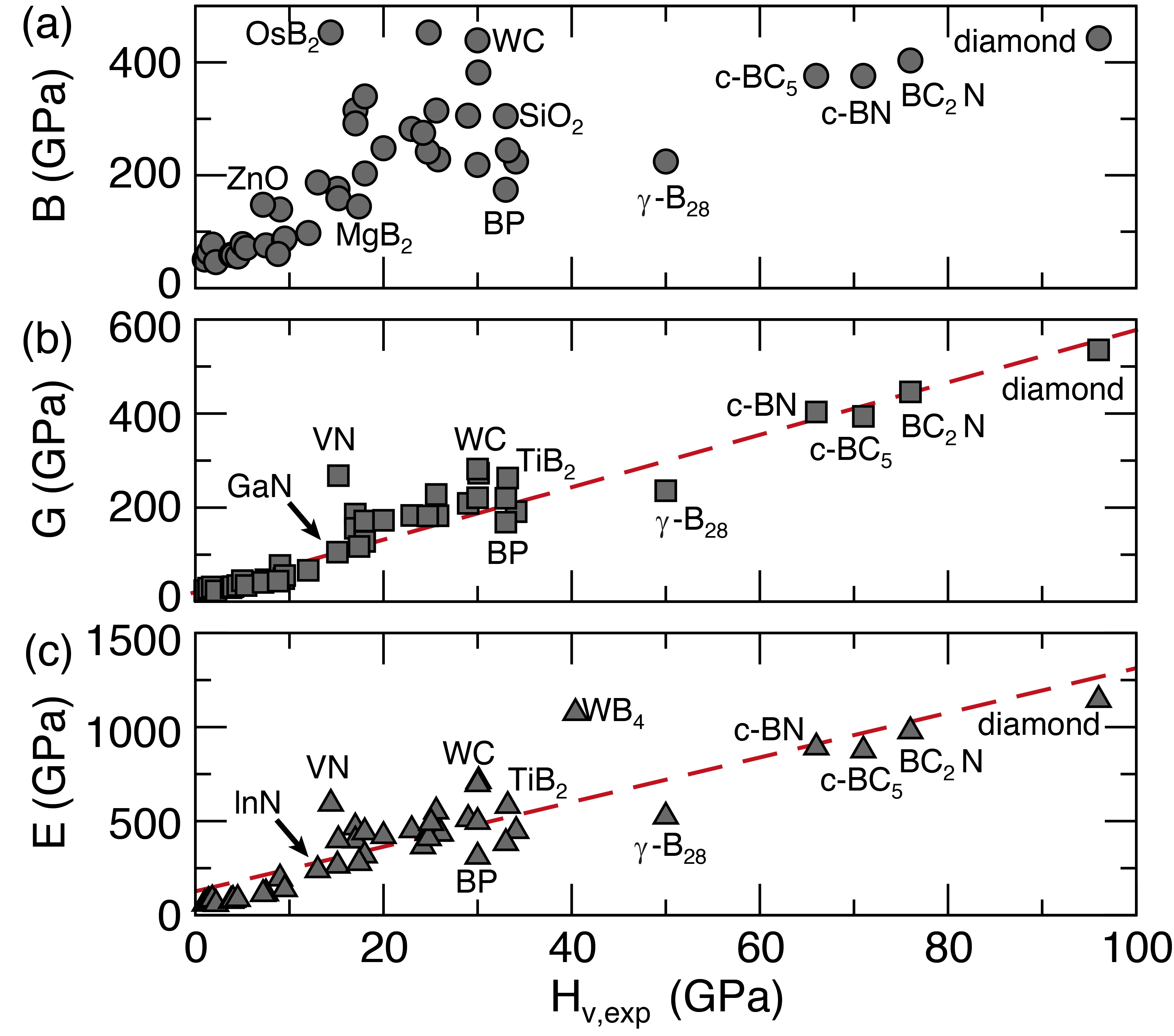

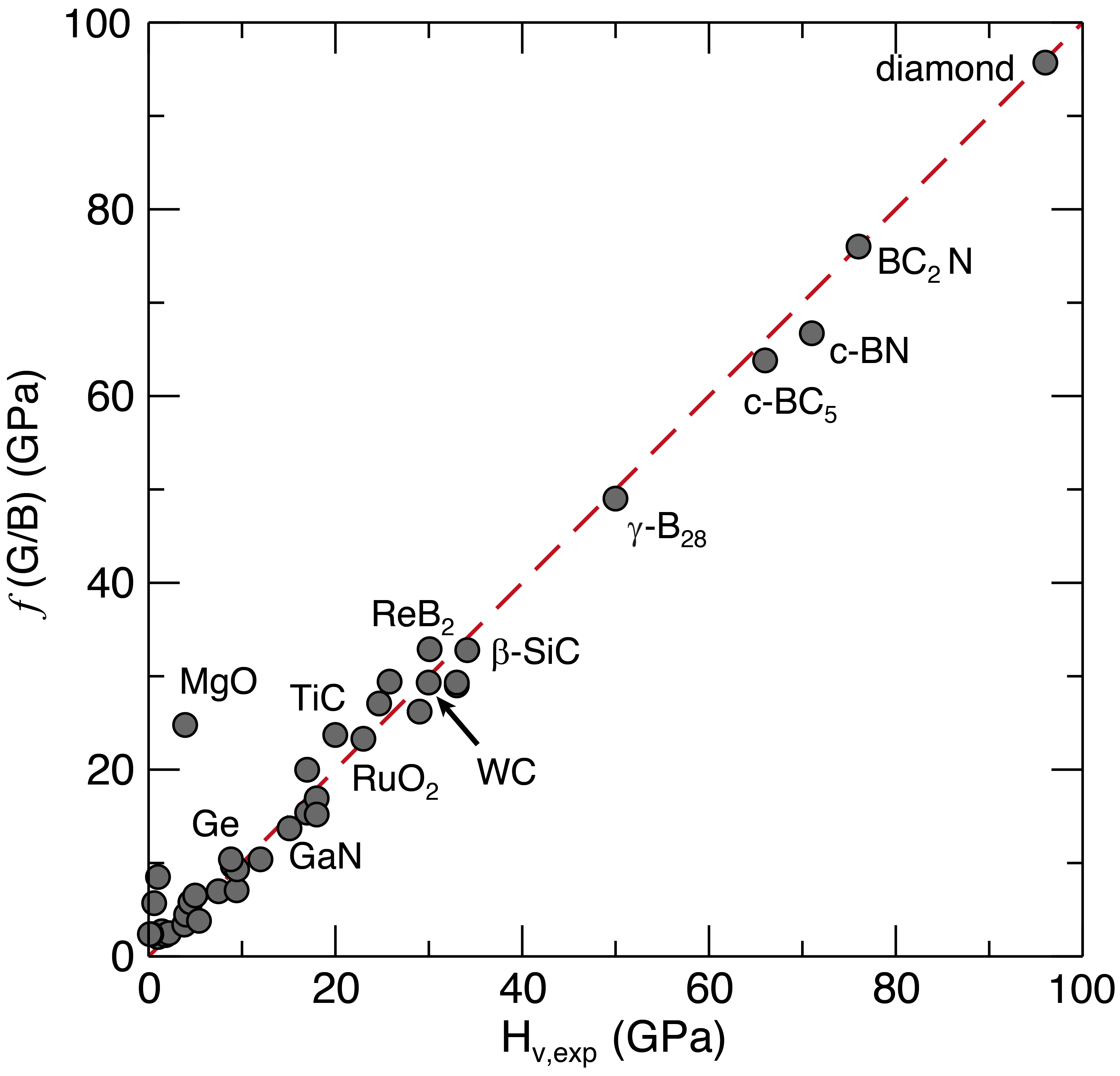

However, one limitation identified by this research is the limited number of reported mechanical properties available in the peer-review literature. Fortunately, my groups expertise in ab initio calculations allows us to calculate a material’s bulk modulus (B) and shear modulus (G) from high level computations of atomic forces. These intrinsic materials properties are related to hardness and therefore can act as a proxy or screening parameter. For example, as shown in Figure 1a, plotting the experimental Vickers hardness (Hv) as a function of calculated B indicates there is minor correlation between these two properties. Plotting Hv against calculated G (Figure 1b) results in a nearly linear correlation. Finally, examining Young’s modulus (E), which incorporates B and G also leads to a linear relationship with the Hv, shown in Figure 1c. From these data, it is evident that shear and Young’s modulus both demonstrate the strongest correlation with experimental hardness; this suggests the feasibility of relating hardness to elastic moduli, which can be easily understood and readily calculated using our ab initio methods. Our research subsequently finds an even better agreement when plotting Hv against a parameterized function involving G and B following the equation f(G/B) = 0.92k1.137G0.708, where k is Pugh's ratio (G/B). This agreement is shown in Figure 2 and indicates that the calculated elastic modulus of B and G are viable to predict a materials hardness.

Figure 1: Correlation of (a) bulk modulus (B) , (b) shear modulus (G), and (c) Young’s modulus (E) with experimental Vickers hardness (Hv). The dashed line is shown as a guide to the eye.

Figure 2: A proposed function to model hardness based on a function of G and B (f(G/B)) is in agreement with experimentally measured Vickers hardness (Hv). The dashed line is the function f(G/B)

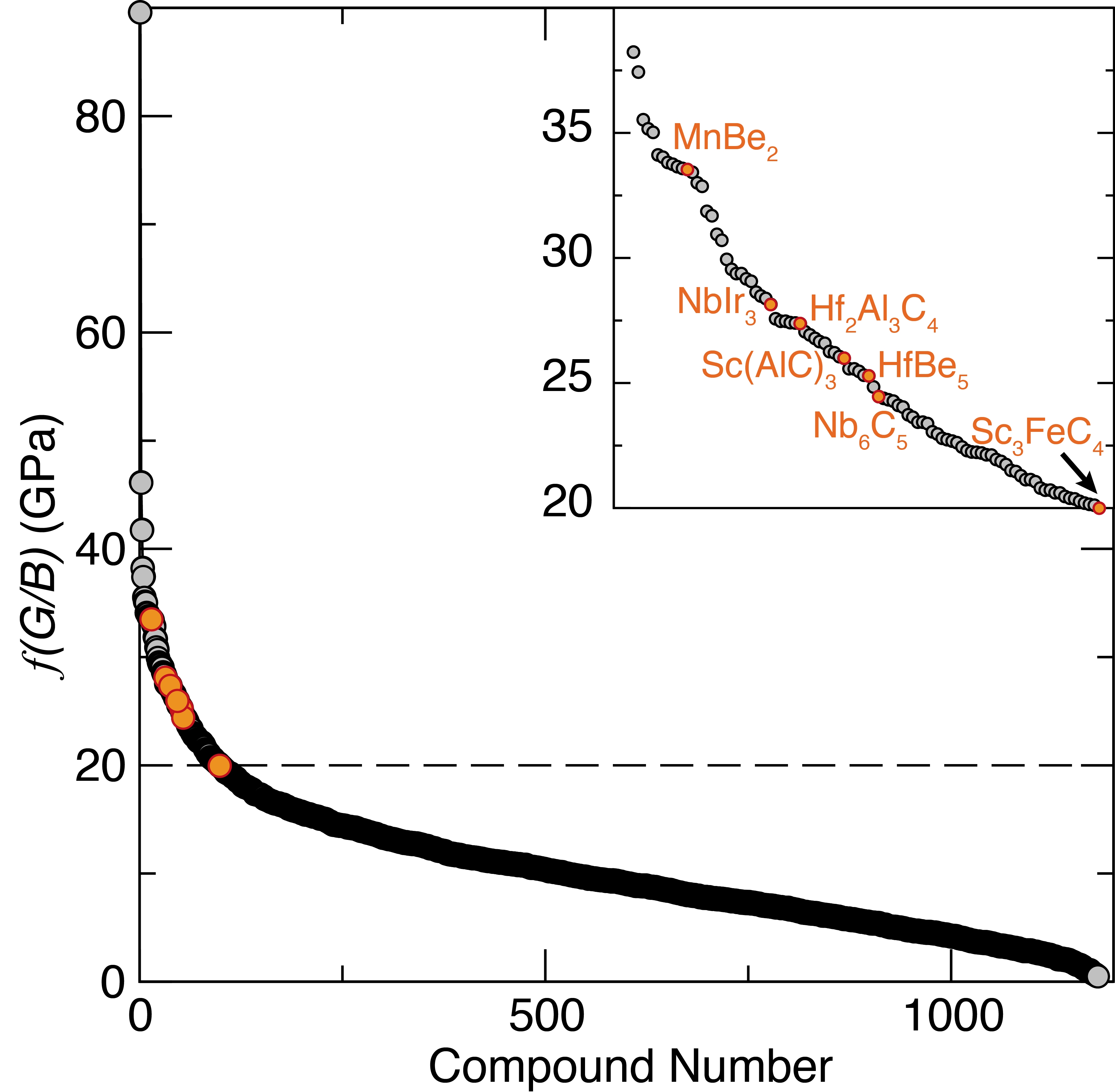

Our research is now using resources developed through the Materials Project to identify compounds with an optimal G and B by screening large crystallographic databases such as the Inorganic Crystal Structure Database (ICSD). In our first attempts, the calculated G and B of over 1100 compounds were employed to calculate f(G/B) as a proxy for Hv. As shown in Figure 3, compounds with f(G/B) higher than 20 GPa (dashed line) are considered as compounds of interest and worthy of experimental consideration. Some specific compositions indicated by the database are HfBe5 (P6/mmm) and MnBe2 (P63/mmc), which both demonstrate potential high hardness with an f(G/B) of 25 GPa and 33 GPa, respectively. More accessible binary compositions that should be considered are Nb6C5 (f(G/B) = 24 GPa) and NbIr3 (f(G/B) = 28 GPa). In addition, there are also noteworthy ternary compositions including Hf2Al3C4 (f(G/B) = 27 GPa), ScAl3C3 (f(G/B) = 26 GPa), and Sc3FeC4 (f(G/B) = 20 GPa). These examples demonstrate that it is possible to target compositions using high-throughput, first principles computation thereby improving the rate of novel superhard materials discovery.

Figure 3: Calculated f(G/B) for the available database. The compounds above the dashed line indicates compounds with a probable f(G/B) > 20 GPa. The inset expands the range above 20 GPa and highlights compositions of interest with an unreported Hv.

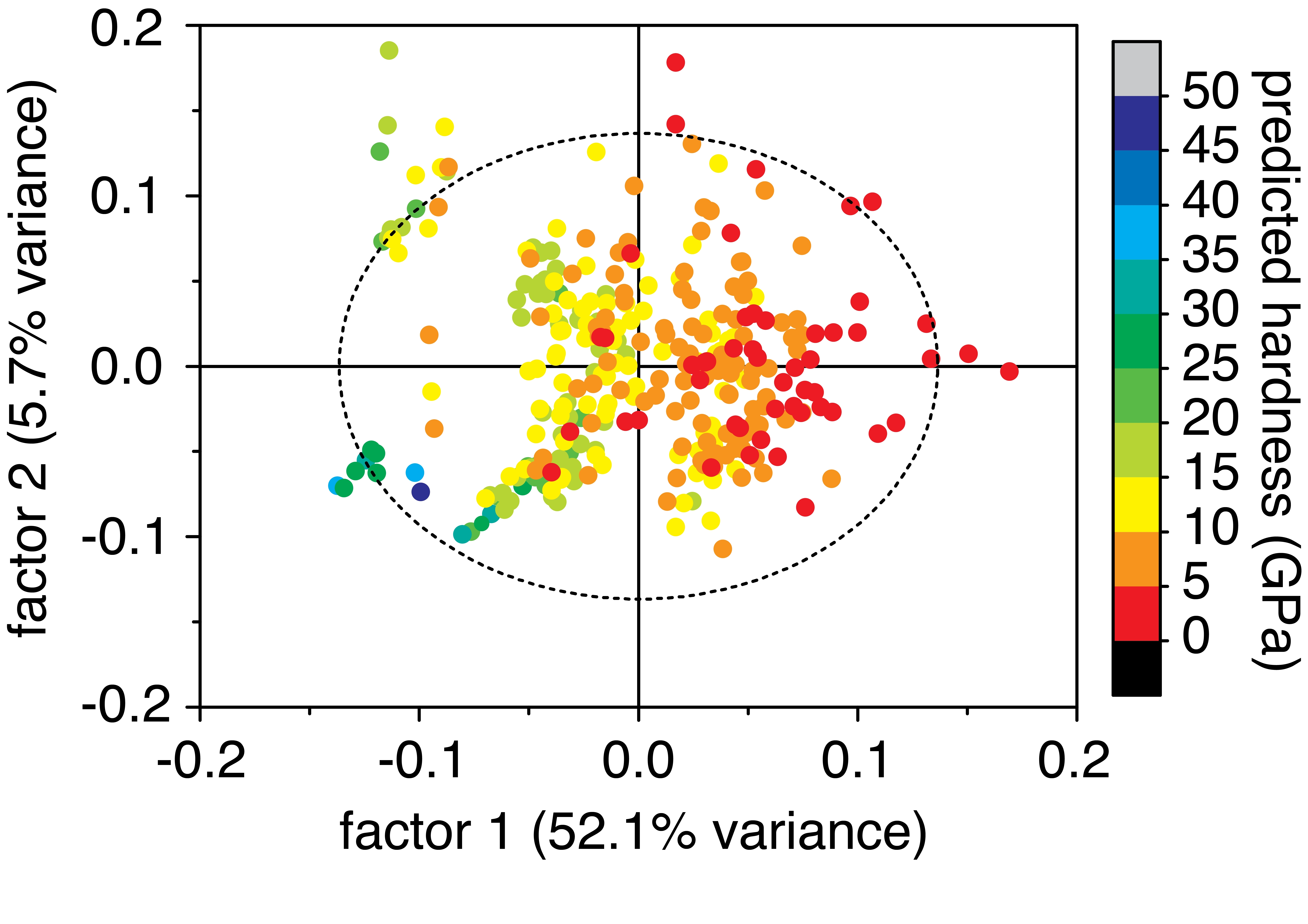

Figure 4: Representation of 432-variable space on two-dimensional plane with color mapping of estimated hardness. The green and blue symbols suggest the most probable high harness materials.

To improve our search, the research has pivoted to more rigorous data-driven, machine-learning tools like partial least squares analysis (PLS). Here, the proxy for hardness (f(G/B)) is described as a set of variables that are based on elemental properties of components. e.g., electronegativity, types of atomic radii, and physical properties of elements such as melting point or ionization energy. In total, 432 variables were considered. A statistical analysis was then developed that by generating linear combination of selected variables, which can be described as Factor 1 and Factor 2, to represent multidimensional data in two dimensions with 57.8% of cumulative variance explained, as shown in Figure 4. From this analysis, NbSi2 was identified as a potential candidate for a material with high hardness according to the machine-learning model within 95% confidence ellipse. Interestingly, this is a phase that was not predicted in in our initial screening efforts (Figure 3).

The subsequent synthesis using an induction heating method showed the purity of the desired phase has been analyzed using powder X-ray diffraction technique showed the product is phase pure. The structure features Si-Si bond as the shortest interaction within the structure and is likely the origin of the possible outstanding mechanical properties. Ongoing laboratory efforts are now focused on preparation of the sample for hardness measurements.