Reports: DNI955159-DNI9: Systems Level Design of Osmotically Driven Membrane Processes for Process Water Reuse

William A. Phillip, PhD, University of Notre Dame

The production of nonconventional petroleum resources is growing. Concurrently, the water demand of these processes is increasing, which leads to mounting pressure to treat produced and process water. This treatment will require an economical technology that can handle complex and difficult industrial water streams. Forward osmosis (FO) is a subset of osmotically driven membrane processes that has potential applications in the treatment of highly impaired water sources. However, there is limited literature on the informed design of FO systems.

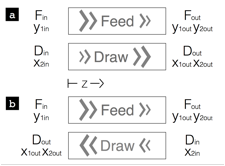

In a FO module, the osmotic pressure difference generated across a semipermeable membrane by a draw solution is used to extract water from an impaired feed stream (Figure 1). Subsequently, the diluted draw solution is sent to another unit that produces fresh water and reconcentrates the draw solution so that it can be recycled. In addition to the exchange of water, the solute concentration differences drive solute transport through the membrane. Because the extents of solvent and solute exchange along the FO module play critical roles in determining the size and energy demand of subsequent draw solute regeneration operations, it is necessary to quantify the effect of membrane properties and operating conditions on the module level performance in order to aid in the evaluation and design of FO systems.

Figure 1. Schematics of (a) co-current and (b) counter-current FO modules. The feed stream, F, and draw stream, D, exchange solutes and water along the module. The volumetric flux of the incoming feed, Fin, contains only feed solute at a molar concentration y1in, and the volumetric flux of the incoming draw, Din, contains only draw solute at a molar concentration x2in. The flux of feed out of the contactor Fout does not equal Fin because water moves from the feed into the draw stream due to osmosis. Due to solute permeation through the membrane, Fout and Dout contain both draw and feed solutes.

In the first year of this project, we have taken a combined experimental and analytical approach to developing a design framework for FO processes. The goal was to express the performance of FO modules in terms of the operating conditions (e.g., the inlet flow rates and concentrations) and the characteristic membrane transport properties (e.g., permeability coefficients). The performance of FO modules was described in terms of two parameters: the recovery rate, R, which quantifies the amount of water extracted from the feed, and the separation factors of the feed solute SF and the draw solute SD , which quantify the amount of solute transferred through the membrane.

An analytical model that quantifies R, SF, and SD as a function of process parameters has been developed and is detailed in a recent publication. The model was validated using numerical solutions of the governing equations (Figure 2) and bench-scale experiments (Figure 3). A commercial cellulose acetate membrane was used in the experiments, which were conducted using a FO cell that mimics a co-current operation. As such, we used the experimental results from this testing device to validate the predictions from our theory.

Figure 2. A comparison of the analytical and numerical solutions for the governing equations. The recovery rate (top) and the draw solute separation factor (bottom) are plotted as a function of the feed solute separation factor. Solid lines and circular markers represent the co-current configuration and dashed lines and triangular markers denote the counter-current configuration. The discrete markers are obtained from numerical solutions and the lines correspond to the analytical solution.

Figure 3. A comparison of experimental results and model predictions for the draw (top) and feed (bottom) solute separation factors. The model developed during the first year of this project was used to calculate the theoretical values. The dashed lines correspond to the uncertainty in the experimental measurements.

Both the numerical solutions and experimental results corroborated the ability of the derived model to predict the performance of a FO module, as long as it operates under the assumptions used to develop the model. In particular, multicomponent interactions, which were not included in the model, were observed in some experiments resulting in poor agreement with the predicted performance. In future iterations, the derived model will be modified to include the possibility of solutes interacting as they permeate. Membranes with chemistries designed to engender solute-solute interactions are currently in development for experimental studies of these effects. However, because the model derived above can describe solute leakage and water recovery for systems where solutes do not interact, it was used in the development of design rules for FO modules.

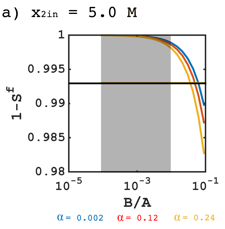

Analysis of the model established membrane selectivity and draw solute concentration as the dominant factors that determine the extent of water recovery and solute rejection. Figure 4 demonstrates how solute rejection varies as a function of the solute permeability, B, and hydraulic permeability, A. The draw solute concentration was fixed at 5.0 M, and the feed solute concentration was varied (0.06, 0.6, and 1.2 M) to be representative of the concentrations found in reclaimed wastewater, seawater, and produced water, respectively. Rejection approached 100% asymptotically as the solute permeability decreased. The shaded region indicates the selectivity of existing FO membranes (10-2 mol L-1 and 10-4 mol L-1).

Figure 4. Feed solute rejection is plotted as a function of membrane selectivity. The shaded region indicates the selectivity of state-of-the-art reverse and forward osmosis membranes. The solid black line at 0.993 indicates the common performance goal for single-pass RO desalination units. A constant recovery of 0.5 was assumed.

Finally, a simple heuristic for selecting the ratio of Din to Fin based on the desired recovery rate and inlet concentrations was identified. Our analysis demonstrated that highly concentrated draw streams operating at a high flow rate, maximize solute rejection at a fixed recovery.

This research project has made a significant impact on the development of graduate and undergraduate researchers at the University of Notre Dame. It has help expand the participation of undergraduate student researchers so that future scientists may connect theoretical principles with hands-on experimentation.