Reports: DNI1054697-DNI10: Understanding the Interfaces Between Iron and Iron-Carbides

Christopher R. Weinberger, PhD, Colorado State University

Research Results

Steel is a ubiquitous in modern society due to its high strength, ductility and low cost. Steel is particularly important to the petroleum industry due to its wide use in both petroleum production as well as in the refining process as a structural material where it can suffer from both mechanical and corrosion failures. While a significant effort has been placed in understanding processing affects the microstructure and hence mechanical properties of a wide range of steels, there are still many unanswered scientific questions regarding the local atomic structure of these microstructures. This research explores one of these topics: the interfacial structure in pearlitic steels. The specific goal of this research is to use atomistic simulation methods to determine the atomic level structure and energetics of the different interfaces between cementite (Fe3C) and ferrite, the two phases of which pearlite is comprised.

Three different interfaces, defined by an orientation relationship (ORs), are commonly reported: the Bagaryatskii, Isachev and Pitch-Petsch. While all three are reported in the literature and our research deals with all three, in this report we will focus on the Bagaryatskii OR due to its frequency of reporting in the literature as well as the high degree of registry between cementite and ferrite in this orientation.

The Bagaryatskii is defined by aligning three high symmetry directions in the cementite and ferrite crystals as:

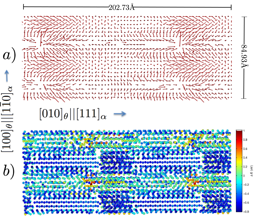

where q denotes the cementite and a for ferrite. These orientations were created in an atomistic simulation and the local atomic was allowed to relax to its minimum energy configuration. Figure 1 shows the atomic level structure in this relaxed configuration highlighting the formation of an orthogonal set of edge dislocations at the interface. The dislocation spacing is predicted well using classical O-lattice theory, suggesting that the interfacial structure is controlled by the well-understood theory of interfacial dislocations which potentially can be modeled using continuum level modeling, which will be discussed shortly.

Figure 1: The atomic level structure of the Bagaryatskii interface as modeled using atomistic methods. (a) the structure highlighted using displacement vectors showing how the atoms relax in the plane (b) the same structure where the atoms are colored by their change in energy.

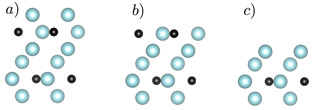

Due to the complex chemistry in cementite (Fe3C), there are three chemically different interfaces that can form at the interface in the Bagaryatskii orientation. Figure 2 illustrates the nature of the different chemistry that is possible to form at the interface. This difference is denoted as the Fe-FeC, FeC-Fe and Fe-Fe iterfaces. The subscrits a and b denote slight differences in stacking orientation, which have no influence on the interfacial energy or strucutres. However, the surface chemistry has a large influence on the energetics of the interfacial energy. The interfacial energies of the different chemical interfaces were found to be: FeC-Fe 0.45 J/m2, Fe-FeC 0.93 J/m2 and Fe-Fe 2.26 J/m2 using a Tersoff potential. The differences in interfacial energy can be linked to interfacial dislocation splitting width and hence their ability to relax in the interfacial plane. While the energy of the dislocation structure and local relaxations change with chemistry, the spacing of the dislocations do not.

Figure 2: Chemically different interfaces can be formed in the Bagaryatskii interface including the (a) Fe-FeC (b) FeC-Fe and (c) Fe-Fe interfaces, which are labeled according to the first two terminating planes.

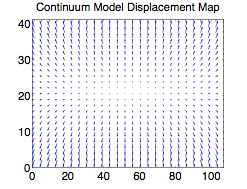

To investigate the use of continuum modeling to represent the interfacial energetics of the Bagaryatskii interface we utilized the formulation of Vattre and Demkowicz to determine the interfacial energy of our atomically determined interfacial dislocations. This method utilizes O-lattice theory to determine the Burgers and spacing of the dislocations in conjunction with anisotropic dislocation theory to predict interfacial energy, from which we found value of 0.57 J/m2, in good agreement with our atomic level results. This continuum model can also plot displacements at the interface, which shows generally good agreement with the discrete atomic level modeling as show in in Figure 3.

Figure 3: The displacement of atoms in the Bagaryatskii interface plane predicted from the continuum model.

These results demonstrate the potential utility in atomic level modeling in understanding interface structure and energetics. It is possible to use continuum level models to get estimates of interfacial energy if the dislocation structure is known from atomistics. However, such analysis misses the important factor of interface chemistry, which has been shown to have a dramatic impact on interfacial energy. Thus, to determine which of all of the pearlite interfaces is most favorable, interfacial chemistry as well as structure must be correctly accounted for.

Impact

The impact of the support from the Petroleum research fund has been in several areas. First, the financial support of the PRF has been used to train one PhD student, Matthew Guziewski. Matthew has excelled under the support of the PRF, and in recognition of this, was awarded the Koerner Family Fellowship for his excellence in research. Under this support, combined with internal support of Drexel University, Matthew was able to attend and present this research at the TMS annual meeting in Nashville TN. Finally, due to collaborations that will be discussed below, Matthew was able to obtain a summer internship with the Army Research Laboratory in the area of modeling material interfaces.

The PRF research has also allowed my group to continue to develop an expertise in atomic level modeling of interfaces. This expertise has developed into a collaboration with the Army Research Laboratory where we are using the tools they have developed to generate atomic models of interfaces to investigate different interfaces in pearlite. This collaboration ultimately lead to Matthew Guziewski getting an internship at ARL this summer.