Reports: DNI553659-DNI5: Selectivity Control of Heterogeneous Catalysis: Designing Selective Reaction Cavities on Well-Defined Metal Surfaces

Chia-Kuang Tsung, PhD, Boston College

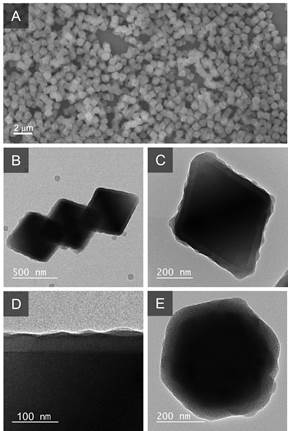

The use of heterogeneous catalysis is at the center of most industrial processes; however, traditional preparation methods lead to the ill-defined active sites. In this project, we propose a new type of heterogeneous catalyst synthesized via coating nanoparticle catalysts with crystalline nanoporous metal-organic frameworks (MOFs). During this second funding period, we have extensively focused on developing new synthetic strategies for coating metal nanoparticles with multiple layers of MOFs. Having a uniform and fracture-free multiple shells is critical for catalysis application. In most of the previous works, integrated MOF layers have similar crystal topologies; for example, the two MOFs are of the same crystal structure but have different functional groups on the linkers or the two MOFs comprise different metal nodes but the linker ligands are the same. Although it could greatly expand the functions of multiple MOF layers materials, no work has been reported on the conformal overgrowth of MOFs with completely different nodes, linkers, and topologies. The challenge lies mainly with the topology mismatch of the different MOFs leading to high interface energy. During the previous funding period of ACS-PRF, we have developed a synthesis by using proper capping agents to minimize these effects for MOFs and metal nanoparticle surfaces. In this second funding period, we use the same strategy to synthesize uniform and fracture-free MOF@MOF particles with MOFs of different crystal structures and chemical properties. We overgrew uniform ZIF-8 shells on monodisperse UiO-66 microcrystal cores to form UiO-66@ZIF-8 composite particles with the assistance of CTAB (Figure 1). In this proof-of-concept material, two stable MOFs of disparate topologies are used: ZIF-8 possesses Zn centers and imidazolate linkers while UiO-66 contains Zr6O4(OH)4 clusters and bicarboxylate linkers. With the assistance of CTAB, we encased a conformal layer of mesoporous silica on the MOF@MOF to form a stable core-sandwich-shell material of hierarchical nanoporous structure. To demonstrate the benefit of combining two distinct MOFs and the importance of the conformal overgrowth, a uniform and fracture-free Pd-UiO-NH2@ZIF-8 catalyst was synthesized, in which UiO-66-NH2 with affinity to metals was used as a core MOF to encapsulate Pd nanoparticle catalysts and ZIF-8 of excellent molecular sieving behaviors was conformally overgrown as shell. Size-selective heterogeneous catalysis over this Pd-UiO-NH2@ZIF-8 was demonstrated. (Figure 2) We believe that this method can be extended to other MOF systems to form a series of core-shell MOF@MOF with mismatched topologies.

The budget during the second funding period was restricted to partial PI summer salary, student salary, meeting travel, and necessary laboratory materials. ACS-PRF funds made it possible to partially support several of my Ph.D. My first two graduate students supported by ACS-PRF grant were graduated in 2015. The ACS-PRF grant also has a great impact to my own career. It helped me to establish this new research direction and create a productive research program. All the results to date are the fundamental data of my NSF and DOE proposals.

Figure 1. A) SEM image of UiO-66@ZIF-8; B-D) TEM image of UiO-66@ZIF-8; E) TEM image of UiO-66@ZIF-8@mSiO2.

Figure 2. TEM images of A) conformal Pd-UiO-NH2@ZIF-8; B) fractured Pd-UiO-NH2@ZIF-8. C) Size selective hydrogenation of conformal Pd-UiO-NH2@ZIF-8, PVP-methanol Pd-UiO-NH2@ZIF-8, fractured Pd-UiO-NH2@ZIF-8, and Pd-UiO-NH2 (from left to right), back columns for ethylene hydrogenation running at 20 ¢XC, front columns for cyclohexene hydrogenation running at 70 ¢XC.