Reports: DNI654267-DNI6: Characterization and Screening of Al-based Olefin Polymerization Catalysts Using Automated Reaction Discovery Approaches

Paul Zimmerman, PhD, University of Michigan

Introduction

Polymerization of olefins produces billions of tons of plastics each year. After Ziegler discovered the original methods for catalytic growth of olefin chains, the majority of research efforts have focused on the use of transition metal (TM) catalysts to drive these transformations. While using Al for olefin polymerization catalysis may be possible and represents an interesting alternative to conventional catalysis, development of Al catalysts remains challenging. In particular, while well-defined Al precatalysts for polymerization have been characterized, the active catalytic species have not been verified and the mechanism of chain growth remains unclear.

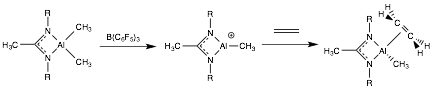

In 1997, Jordan found that cationic Al alkyls with amidinate ligands can polymerize ethylene (see Figure 1), marking the first appearance of a designed Al-ligand complex for olefin polymerization. By activating the Al dimethyl amidinate by a methyl-abstraction reagent, e.g. B(C6F5)3, the Al center becomes cationic and ready for olefin coordination. Upon reaction with ethylene, high molecular weight polymers with polydispersities of around 2-3 were formed.

Figure 1. Aluminum amidinate precatalyst for olefin polymerization (left), activation (middle) and coordination of first olefin monomer (right).

This example and other efforts in this area have been driven by the assumption that three-coordinate cationic Al complexes are sufficiently Lewis acidic to bind and insert olefins. Three-coordinate Al complexes, however, are inherently unstable. While three coordinate complexes are naturally desirable for higher activity, at the same time coordination and reorganization of potential ligands or other Al complexes becomes probable. Overall, low-coordinate Al complexes can display a range of behaviors that are difficult to interrogate under catalytic conditions. These challenges have made investigations into such complexes difficult, as well-defined catalyst active species have yet to be isolated.

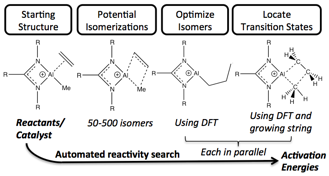

The reaction discovery tool developed in the Zimmerman group, called ZStruct, is ideally suited for investigating Al olefin enchaining catalysis because it does not require that the operative reaction mechanisms be known beforehand. ZStruct uses graph theory to generate a highly plausible set of reaction hypotheses, and then uses the Growing String Method to optimize these reaction paths and evaluate thermodynamics and kinetic barriers. Vitally, all of the energetics are evaluated at a quantum chemical level of theory, allowing high accuracy to be easy attained. A schematic of this methodology is shown in Figure 2.

Figure 2. ZStruct and Growing String Method for Reaction Discovery. All steps beyond specifying the reactant/catalyst structure are performed by the software.

Results and Discussion

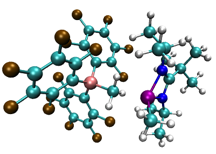

The activation of the dimethyl Al amidinate was found by ZStruct to proceed through SN2 attack of the B(C6F5)3 boron on one of Al's methyl groups, causing inversion of the CH3 at the transition state. This transition state is facile, with a barrier of only 10 kcal/mol. After this elementary step, the B(C6F5)3CH3 species remained bound to the Al, but only weakly. Having determined that methyl abstraction at the Al precatalyst proceeded as expected, we turned to investigate possible mechanisms for chain growth at the monomethyl Al amidinate.

Figure 3. Dimethyl Al amidinate complex activated by B(C6F5)3.

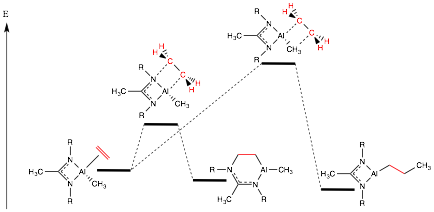

Upon applying the ZStruct methodology to the activated Al complex, we were surprised to find that the chemistry of this cationic amidinate did not follow the expected Cossee mechanism for olefin insertion. Figure 4 shows that the standard insertion mechanism is outcompeted by insertion of the ethylene into the Al-N bond, creating an expanded 6-membered ring of the amidinate ligand. This behavior relieves the ring strain of the 4-membered amidinate, making the barrier 18 kcal/mol lower than standard insertion. Furthermore, this insertion was downhill by 3 kcal/mol, indicating that the product of the rearrangement is relatively stable.

Figure 4. Competition between standard insertion and Al-amidinate insertion mechanisms.

This catalyst modification has important implications on the mechanism for catalysis. First, the 4-membered ring Al amidinate is unstable, making it unlikely to be the true catalyst for olefin polymerization. This result suggests why previous computational investigations could not find operative mechanisms for polymerization at the monomethyl Al cation with this ligand. Furthermore, subsequent insertions of additional olefins can now occur via the standard Cossee mechanism, but they may compete with additional olefin insertion into the amidinate.

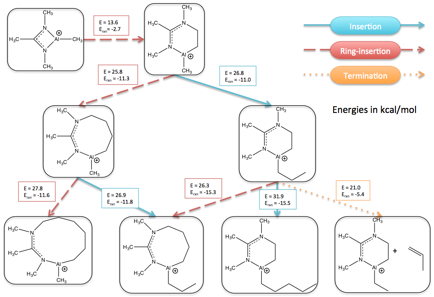

Subsequent simulations were run to probe the ability of additional ethylene monomers to insert into either of two possible positions. Figure 5 shows the results of this analysis, which suggest that standard and ring insertions are in close competition with one another after forming the 6-membered ring Al complex. For instance, after the first ring growth step, additional ring growth occurs with a barrier of 25.8 kcal/mol compared to 26.8 kcal/mol for regular insertion. Both steps are thermodynamically favorable due to the C-C bond formation, and are down hill more than 11 kcal/mol. From the 8-membered ring, ring growth and regular growth are again in competition, with barriers within 1 kcal/mol of each other and similar thermodynamic favorability. In sum, since ring growth continues, the Al amidinate eventually transforms into a species that resembles an Al alkyl.

Ongoing reaction discovery simulations are showing that the nitrogen displaced by ring growth can reattach to the Al center at the 8-membered ring species, and this may allow more facile Cossee polymerization. Furthermore, ongoing investigation of the competition between chain growth and termination at the species shown in Figure 5 will describe the entire network for these reactions, allowing a complete mechanistic and kinetic analysis of this chemistry.

Figure 5. Multiple insertions into ring and polymer chain of activated Al amidinate.

Conclusions

The reaction discovery tool, ZStruct, showed that unexpected mechanisms for olefin insertion are highly plausible for Jordan's Al amidinate complex. Importantly, the discovery of thermodynamically and kinetically viable ring insertion means that all hypotheses and analyses require consideration of this complex. The reaction network of Figure 5 is currently being extended to a variety of isomerizations and competitive pathways for polymer growth and termination. Overall, these results will be able to determine how olefin polymerization may occur at Al centers, and lead to the design of more stable active complexes for control over chain growth.