58th Annual Report on Research 2013 Under Sponsorship of the ACS Petroleum Research Fund

Reports: ND852387-ND8: Pressurized Hydraulic Fracturing of the Devonian Marcellus Shale with Liquid CO2: Impact on Enhanced Gas Recovery

Alan J. Kaufman, University of Maryland

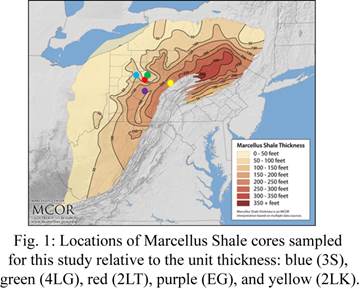

The primary goal of our ACS-PRF funded research is to determine the quantity and distribution of recoverable hydrocarbons extracted from core samples of the gas-prone Marcellus Shale using supercritical CO2. Supercritical CO2 extractions have previously been successful in the recovery of a wide range of nonpolar polycyclic aromatic and aliphatic hydrocarbons from different source rock matrices under varying extraction conditions. In this study, we evaluate the liquid hydrocarbon extraction efficiency of supercritical CO2 relative to standard techniques and focus on how recovery varies with respect to shale particle size distribution. Samples for supercritical CO2 extraction and time-series studies were collected from four rock cores intersecting the Devonian-aged Marcellus Shale at depth (ranging from 6800 to 8000 feet) in western Pennsylvania (EXCO Resources, Inc., Salt Lake City, Utah), along with one additional Marcellus core (Pennsylvania Geological Survey) (Fig. 1).

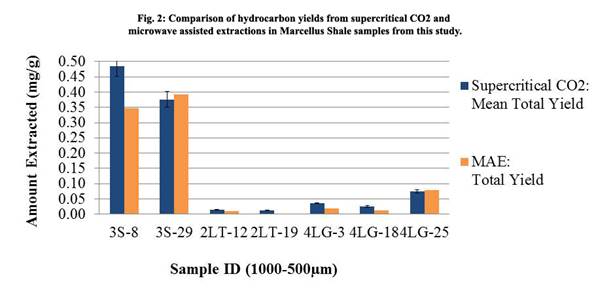

To assess the resource potential (quantity, quality, and thermal maturity) of the shale samples, Rock-Eval pyrolysis was performed on selected Marcellus shale samples (GeoMark Research, LTD) with a Rock Eval II Instrument. Total organic carbon (TOC) was determined on powders previously reacted with HCl with a LECO C230 elemental analyzer. Based on these results, seven samples were chosen for further geochemical characterization and supercritical CO2 extractions. Criteria for selection was based on the highest TOC (>1.0 wt%) and S1 values (>0.70mg hydrocarbon/g bulk rock). The selected samples had a TOC range between 1.5 and 6.2 wt. %. Solid bitumen reflectance (Ro) of these samples confirms their high level of thermal maturation associated with deep burial (range between 2.2 and 2.6% Ro), and suggests that solid pyrobitumen constitutes the bulk of the TOC present in the analyzed samples. Microwave assisted extractions with a 50/50 mixture of acetone and dichloromethane performed on a MARS 5 System showed successful recovery of aliphatic hydrocarbons from all samples. However, yields were comparable or slightly higher with extractions performed on an Isco, Inc. SFXTM 220 Supercritical Fluid Extraction System (Fig. 2).

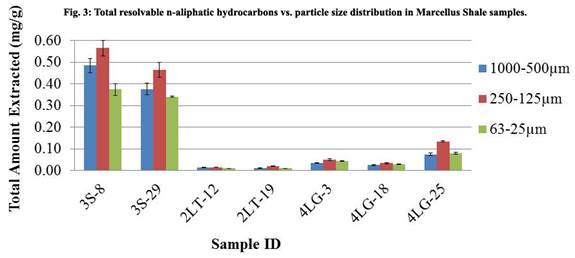

Supercritical CO2-extractions (1000-500µm, 250-125µm, and 63-25 µm particle size fractions) produced measureable quantities of n-aliphatic hydrocarbons ranging from n-C11 through n-C21. Total recovery ranged from approximately 0.01 to 0.6 parts per thousand or ~0.03-1.2% TOC. The distribution and quantity recovered is consistent with the high maturity of the shale cores. Notably, the recovery of total n-aliphatic hydrocarbons was greatest in the 250-125µm size fraction (Fig. 3).

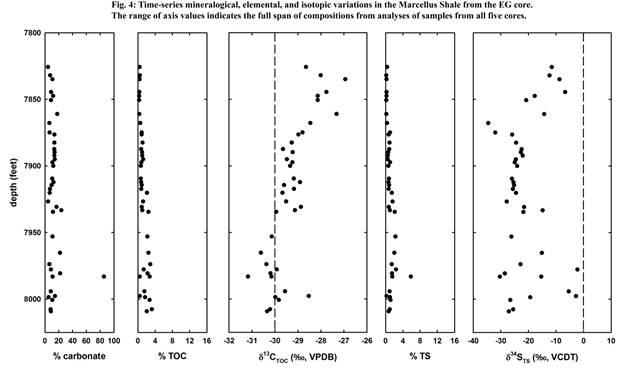

Variations in quantity of recoverable hydrocarbons among different cores may be related to the content of organic matter and other mineral constituents in the core samples, as well as the porosity of the shale and exposed surface area. To further characterize the sedimentological and geochemical aspects of the cores we conducted high resolution time-series analyses of the percent of carbonate, TOC, and total sulfur, as well as the carbon and sulfur isotope compositions of organic matter and pyrite, respectively (Fig. 4). Organic carbon and sulfur abundances are similar in the Marcellus core samples supporting an open marine depositional setting. The high sulfur contents of these rocks in particular may explain the unusual n-alkane distributions at the presence of a large unresolved hydrocarbon signal. The time-series graphs are revealing. In all the cores, regardless of the measured thickness or facies, there is enrichment of organic carbon and total sulfur in the lower half and a significant rise in 13C abundances from the bottom to the top. In addition, all cores exhibit a significant jump in 34S abundances in the upper reaches. These variations likely reflect changes in the source of organic matter, with the more negative carbon and sulfur isotope values reflecting more open marine conditions.

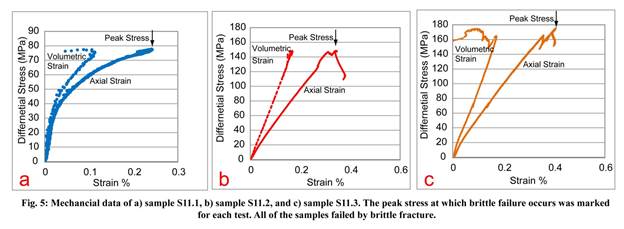

Porosity and permeability measurements (with an ULTRAPore He porosimeter and an ULTRAPerm N2 permeamenter, respectively) as well as hydro-mechanical deformation experiments on a typical sample were conducted to further characterize the Marcellus Shale. Deformation tests on the Marcellus sample (cored at three different angles relative to bedding) were performed using an Autolab1500 apparatus. Samples S11.1 and S11.2 were deformed at a confining pressure of 15MPa, and a strain rate of 1x10‑6 /s. Sample S11.3 was deformed at a confining pressure of 30MPa, corresponds to the in-situ effective stress at the depth at which the drill core was taken. The strain rate for S11.3 test is 1x10‑6 /s (Fig. 5).

The mechanical data show that shear strength and elastic moduli of the Marcellus samples depend strongly on bedding laminations. At the same confining pressure and strain rate, the deformation data show that the shear strength of the bedding parallel sample S11.2 is only ~1/3 of that of the bedding perpendicular sample S11.1. Fractured samples were retrieved and measured for porosity and permeability after the deformation tests. To test the pressure dependence of permeability, measurements were conducted at different pressures during both loading and unloading cycles. Compared to the permeability values of respective undeformed samples, more than two orders of magnitude permeability increase was observed in the mechanically fractured samples. Micro-structure observations show that crack growth in the deformed Marcellus samples is controlled by the interplay between stress, laminations, and the contrast in strength between silt- and clay-rich layers. The stress-induced cracks are generally sub-parallel to the maximum principal stress. Changes in crack orientation are observed along bedding laminates and clay minerals.

Copyright © 2014 American Chemical Society