58th Annual Report on Research 2013 Under Sponsorship of the ACS Petroleum Research Fund

Reports: UNI851245-UNI8: Enhanced Oil Recovery by Analysis and Control of Vortex Flow in Porous Media

Fatemeh Hassanipour, PhD, University of Texas (Dallas)

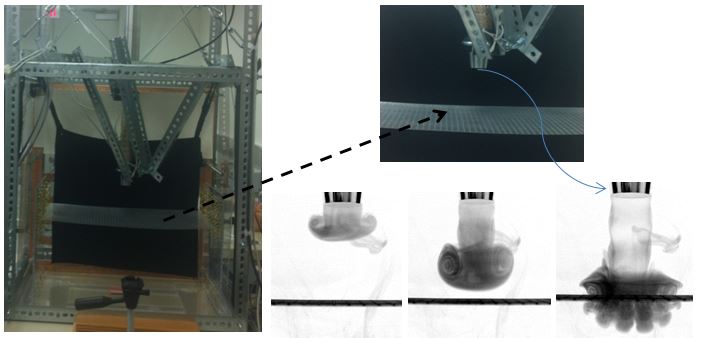

1. Experimental Setup: After finishing the construction of the experimental setup, several experiments were conducted in small scale using silicon oil as the carrier fluid and packed glass beads for the porous medium. Successful results were obtained, however, the cost of the silicon oil and the practical difficulties of the maintenance of the apparatus when used with silicon oil led us to a change of methodology. In a new approach, airflow is applied instead of silicon oil. A fog generator in conjunction with the fully controlled piston vortex ring generator creates the votex flow. The airflow pattern can be captured by a CCD camera. The advantage of the new methodology is that the results can be easily repeated and reproduced without the consumption of oil and the maintenance issues are minimal.

A series of wire-mesh screens arranged in an acrylic box replaced the glass bead porous medium. The screens are made by regular acrylic rods with small diameter. Exact values of porosity can be implemented by the distance between the acrylic rods. The orientation, thickness, and distance of the rods within each screen, as well as across different screens, reflect the complexity and geometry of the porous medium. Using these variables, the hydraulic properties of permeable media, including porosity and permeability, can be emulated within a certain range. Thus, a number of different porous media can be constructed and tested in this way.

So far, the interaction of airflow vortex with three porous media with porosity 30% (fine), 60% (medium) and 80% (coarse) has been observed. The impingement velocity varies with Reynolds number of 600, 900,1800 and 4500. The effects of vortex ring impingement and porosity variation on the flow propagation of air vortex though one porous screen are obtained. A journal paper is under preparation reflecting the results of this study.

2. Student Involvement and Educational Component: One full time and one part-time graduate student worked on this project during 2012-2013. The graduate students were responsible for producing preliminary results for propagation of vortex flow through the glass bead porous medium, with silicon oil as fluid, in small scale. The graduate students also programmed the control system for the actuator and the data acquisition module. One of these graduate students has graduated and joined the workforce.

Copyright © 2014 American Chemical Society