58th Annual Report on Research 2013 Under Sponsorship of the ACS Petroleum Research Fund

Reports: ND950928-ND9: Synthesis and High Pressure Gas Separation Properties of Thin Metal-Organic Framework Membranes

Jerry Y.S. Lin, Ph.D., Arizona State University

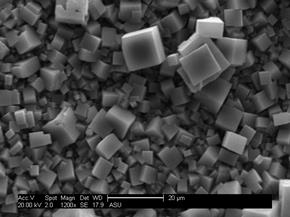

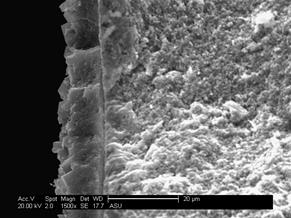

Research conducted in the report period (9/1/2012-8/31/2013) was focused on improving synthesis of thin metal-organic framework membranes (MOF-5) and membrane characterization. In previous year large MOF-5 seed crystals were prepared and then ground by a mortar and pestle to reduce the particle size. Now the powders were ball milled in a Teflon container, with alumina balls, in an Across International PQ-N04 Planetary Ball Mill. The ball milled MOF-5 crystal seeds, between 1 and 3 µm in sizes, were added at a concentration of 2 wt% to dimethylformamide and ultrasonically agitated to create a stable MOF-5 suspension for dip-coating. Thin, uniform MOF-5 seed layer was obtained on macroporous alumina support, which was then grown to a continuous MOF-5 membrane in a secondary growth step. Figure 1 shows a MOF-5 membrane prepared by this improved method. It comprised of MOF-5 crystals mostly in 5 to 10 µm, with a few large crystals between 10 and 20 µm in size. The MOF-5 membrane has a cross-sectional thickness of 10 µm. Because of the reduced crystal size, the membranes prepared with the improved method are about 50% thinner than the membranes prepared earlier in this project. Moreover, the size reduction of MOF-5 crystals by ball-milling gave a much better control in reproducible coating of MOF-5 seed layers, and hence a improved quality of the final MOF-5 membranes.

Pervaporation molecular probing method was suggested as a method to test the quality of MOF-5 membranes for gas separation. The pervpoaration stability issue should be examined before this method can be used effectively for this purpose. On-stream p-xylene pervaporation test of the as-synthesized MOF-5 membrane shows the p-xylene flux declines and levels off at a steady-state value about 70% of the original value for fresh-membrane after 16 hours on the stream. The p-xylene flux cannot be restored to the original value, suggesting permanent fouling of the MOF-5 membrane upon exposure to p-xylene stream. Subsequent characterization indicated there was no structural or microstructural degradation that occurred, and evidence of retained xylene isomers in the MOF-5 structure was found using Fourier transform infrared spectroscopy. Nevertheless, the fouled MOF-5 membranes exhibit stable pervaporation fluxes for organic molecules with sizes smaller than the aperture of the MOF-5 cage, and exclude organic molecules with sizes larger than MOF-5 aperture.

The results show that the MOF-5 membranes, after a permanent reduction in permeation flux by initial exposure to xylene stream, are stable in organic solvent and can be used for separation of liquid organic molecules based on the molecular sieving effects. Furthermore, pervaporation molecular probing tests should be conducted with fresh or regenerated membrane under a controlled condition for each probing molecules in order to obtain reliable data to examine the quality of the MOF-5 membranes for gas separation. Work will continue in the final year of this project to study gas separation properties of the improved MOF-5 membranes with reduced thickness.

Figure 1 SEM photomicrographs of MOF-5 membrane surface morphology (left) and cross-sectional view (right) prepared by the improved method.

Copyright © 2014 American Chemical Society