Back to Table of Contents

46117-AC5

Nanofiber Catalyst Supports and Solution-Based Processes for Deposition of Catalytic Metals and Metal Oxides

Wayne E. Jones, State University of New York at Binghamton

The adsorption of stabilized

metal nanoparticles on metal oxide nanostructured materials confers profound

prospects to catalysis in organic synthesis.1,2 These include; ease

of recovery and recyclability of these catalysts from reaction medium, large

surface area to volume ratio, as well as stability at high temperatures that

are fundamental in production and refining of petrochemicals.3,4 The

bottom-up approach and solution-based fabrication processes provide low cost

catalysts with a low catalyst loading, good selectivity, and enhanced

reactivity under mild conditions. This is attributed to novel properties

accrued to nanomaterials relative to bulk materials due to quantum level

interactions.5 In phase one of the PRF progress, we report a simple

template based approach via electrospinning of

fabrication of titanium dioxide (TiO2) nanostructures followed by solution

based impregnation and reduction of palladium nanoparticles onto TiO2

nanostructured supports. These catalysts (Pd-TiO2) were applied in

Heck C-C coupling reactions to determine the conversion rate, selectivity and

stability of the catalysts.

Electrospinning provides an

inexpensive, straightforward route to the fabrication of high surface area

fiber membranes.6 This process entails the application of an

electric field to a polymer solution or

composite leading to generation of fibers on nanometer scale, and was exploited

in fabricating nanofibers and nanotubes. Nanotubes were synthesized by a fiber-based

template process, where electrospun fibers

served as a scaffold upon which a metal oxide

precursor was deposited via sol gel

process whereas nanofibers were fabricated via electrospinning a composite

mixture of titanium isopropoxide (TiP)/polymethylmethacrylate (PMMA) as illustrated by the

following schemes.7,8

PMMA/TiP composite fibers |

PMMA/TiP(1:2) in CHCl 3/DMF(1:1) |

aa Scheme 1: Fabrication of metal oxide nanofibers

|

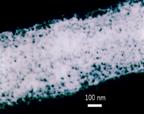

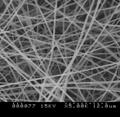

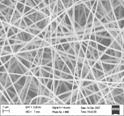

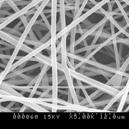

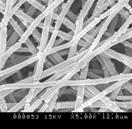

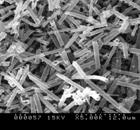

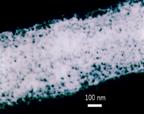

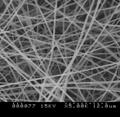

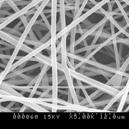

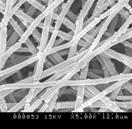

(a)Scanning Electron Microscopy (SEM)

image of electrospun composite PMMA/TiP (b) TiO2

nanofibers after pyrolysis at 400°C, with diameters 150±50 nm

(d) Transmission Electron Microscopy image TiO2 nanofibers (150±50

nm) (d) Pd nanoparticles on TiO2

nanofibers with diameters range 6-10 nm.

The morphology of fabricated composite

fibers was smooth with dimensions ranging between 150±50 nm in

diameter. Pyrolysis temperature, 400°C, was based

upon thermogravimetric analysis of the degradation

profile of PMMA. FTIR and Powder X-ray diffraction confirmed complete removal

of organics leaving behind an anatase crystalline phase of titania. Pd nanoparticles were uniformly distributed with 5% loading and diameters ranging between 6-10

nanometers over the TiO2 support. Nanoparticle impregnation |

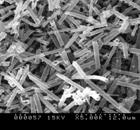

Scheme 2: Fabrication of metal oxide nanotubes by templating |

Catalyst supported on nanotube |

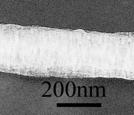

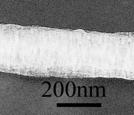

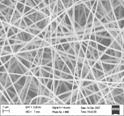

SEM images (a) Electrospun polylactide, PLA, template with diameters 200±50 nm (b) PLA-TiO2

coaxial fibers after sol gel coating

with diameters 250±100

nm (c) TiO2 after pyrolysis at 400 °C,

diameters 200±50 nm and wall thickness

~100 nm.

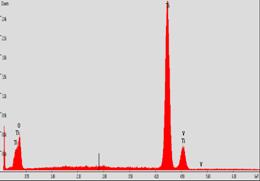

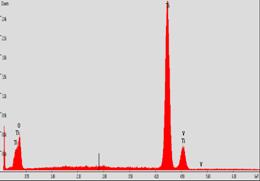

(a)Thermogravimetric analysis,

TGA, illustrating the thermal decomposition of polylactide polymer (b) Infrared

spectrum before and after calcinations indicating

complete degradation of PLA

polymer (c) EDS indicating TiO2 formation (d) Powder X-ray

diffraction indicating anatase crystalline phase of TiO2 nanotube.

Pd-TiO2 catalysts fabricated were tested for Heck C-C coupling of Iodobenzene with

scheme (3) styrene and

scheme (4) n-butylacrylate.9,10

The reactions were carried out in an air and comparisons were made with (a) Pd/C in an inert atmosphere,

(b) Pd(OAc)2 as

unsupported powders.

Scheme 3: C-C coupling of iodobenzene with styrene

Scheme 4: C-C coupling of iodobenzene with n-butylacrylate

From the GC, Pd-TiO2 showed

higher conversion of reactants to products compared to Pd(OAc)2

complex, and comparable rates to those given by Pd/C (the

commercially obtained catalyst) even though reaction with Pd-TiO2

was manipulated under air atmosphere. Pd-TiO2 catalyst exhibited high activity and selectivity for the

desired product even at 0 minute reaction time, with yields comparable to Pd/C.

The yield of stilbene was constant and increased exponentially indicating

stability of the product and catalyst up to 200 minute reaction time. The Pd-TiO2 catalysts

recorded selectivity values of up to 100% and high yields of up to 83% as

calculated from GC relative areas. In addition Pd-TiO2 was

effectively eliminated from the final products by filtration as compared to

unsupported Pd(OAc)2 and

Pd/C catalysts. Similar trends were observed for C-C coupling of

iodobenzene with n-butyl-acrylate.

Work in progress is geared

towards mechanistic studies to understand the nature of very active metal

species in solution. Similarly, related work

is underway on fabrication and characterization of gold nanoparticles and other

metal oxide nanostructured supports such as ZnO and ZrO2 and their

application to Heck and Suzuki C-C coupling reactions.

Back to top