47143-G7

The Effects of Polydispersity on the Melt Phase and Aqueous Solution Phase Behavior of ABA-Triblock Copolymers

Overview. Block copolymers and related polymer surfactants combine two or more chemically dissimilar homopolymer blocks into a single macromolecule. Neat block copolymers self-assemble in the melt-phase and in the solution-phase to produce well-defined nanostructured materials. These materials find widespread applications as thermoplastic elastomers, pressure-sensitive adhesives, and as non-ionic surfactants for cosmetics and enhanced oil recovery. The phase behavior of block copolymers comprised of two monomers having narrow molecular weight distributions has been well studied. Production of monodisperse block copolymers requires demanding synthetic conditions that contribute considerably to their cost, and the resulting materials are known to often exhibit unfavorable processing characteristics that limit their utility. Systematic experimental explorations of the influence of molecular weight polydispersity on the phase behavior of block copolymers and their related surfactants are scarce. Therefore, we are examining the fundamental effects of selectively incorporating polydisperse center segments into ABA-type triblock copolymers on their melt-phase behavior and their dilute solution-phase behavior. Our initial studies focus on two ABA-type triblock copolymer model systems: (1) poly(styrene-b-1,4-butadiene-b-styrene) (SBS) and (2) poly(ethylene oxide-b-1,4-butadiene-b-ethylene oxide) (OBO). These systems both offer opportunities to study the melt-phase behavior of weakly segregated block copolymers, while the latter system enables studies of the dilute solution behavior of polydisperse amphiphiles. Our preliminary results indicate that the quiescent melt-phase behavior of polydisperse SBS triblock copolymers is dramatically different from that of their monodisperse counterparts.

Melt-phase

behavior of SBS triblock copolymers. ROMP-CT

of 1,5-cycloctadiene in the presence of 1,4-dibromo-2-butene catalyzed by

Grubbs'-type catalysts produces a,w-dibromo-poly(1,4-butadiene) with Mw/Mn = 2.0. Subsequent atom transfer radical polymerization

(ATRP) of styrene in the presence of a copper(I) catalyst produces SBS triblock

copolymers. Selective catalytic degradation of these triblock copolymers with

OsO4/H2O2 demonstrates that the poly(styrene)

end blocks have polydispersities Mw/Mn ² 1.15. By this methodology, one

graduate student and one undergraduate student supported by ACS PRF funding over the last 12 months have produced a

library of 40 fully characterized polymers having a range of compositions and

molecular weights.

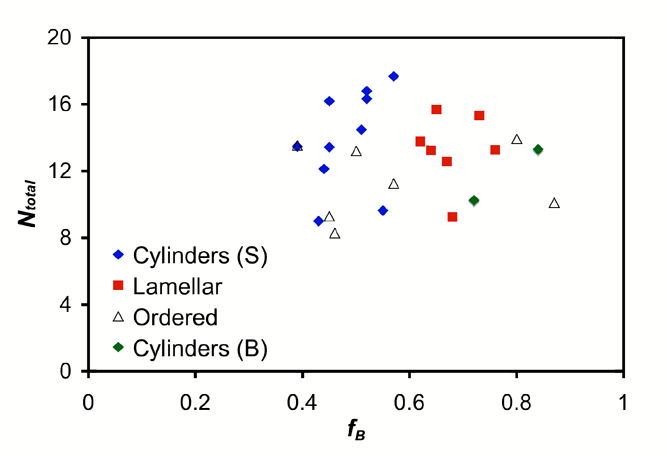

Polydisperse

SBS triblock copolymers microphase separate into ordered structures having

variable degrees of long-range order as evidenced by small-angle x-ray

scattering. Temperature dependent SAXS analyses of the ordered melts at

symmetric compositions (fstyrene = fbutadiene = 0.5) reveal large increases

Figure 1. A tentative phase diagram for polydisperse SBS triblock copolymers. in the order-disorder transition

temperatures, indicating substantial stabilization of the polydisperse melts.

In contrast to monodisperse SBS triblocks, the polydisperse melts adopt a

cylindrical morphology at symmetric compositions instead of the typically

observed lamellar structure. Synchrotron SAXS further demonstrates that some of

the samples exhibit coexistence of microphase separated morphologies, e.g. a mixture of lamellae and hexagonally packed

cylinders. A tentative phase map for these triblocks copolymers is given in

Figure 1, which indicates that the phase boundaries for polydisperse melts

shift dramatically and the intermaterial dividing surfaces curve toward the

polydisperse segment. Current work focuses on corroborating the results of SAXS

analyses using transmission electron microscopy to provide real-space images of

these ordered structures.

Solution-phase

behavior of OBO triblock copolymers.

Employing a variant of the synthetic strategy described above, ROMP-CT provides

ready access to a,w-dihydroxy-poly(1,4-butadiene) with Mw/Mn = 2.0. Anionic ring-opening polymerization of ethylene

oxide initiated from the hydroxyl termini yields OBO triblock copolymers, with

monodisperse O blocks. We are currently optimizing the synthesis of these

materials for future studies of their melt-phase behavior and aqueous solution

phase behavior. We anticipate that these triblocks will exhibit different

properties from their monodisperse counterparts, which may lead to novel

rheological modifiers that are readily produced using scalable chemistries.

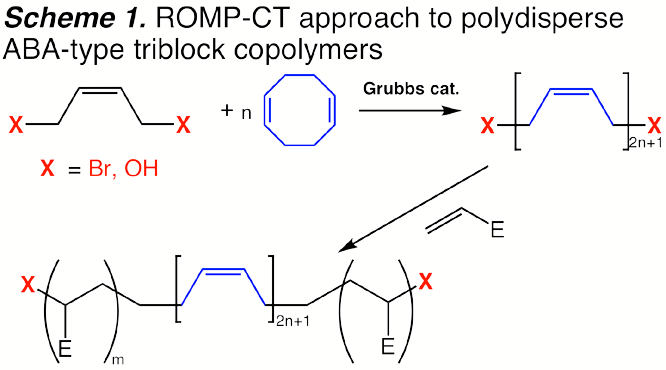

General

Synthetic Strategy. Our synthetic strategy

relies on well-known methods in chain transfer ring-opening metathesis

polymerization (ROMP-CT) to produce difunctional telechelic polymers with a

polydispersity Mw/Mn = 2.0. By installing functionalities at the chain ends

that enable the controlled/"living" polymerization of a second monomer,

ABA-triblock copolymers are readily produced in which the A end blocks are

monodisperse (Mw/Mn ² 1.15) and the center B block is

polydisperse (Scheme 1). Polymers derived from this methodology in which the

center block is poly(1,4-butadiene) from ROMP of 1,5-cyclooctadiene offer an

advantage over other systems of interest: selective degradation of the

polydisperse poly(1,4-butadiene) block enables direct analysis of the molecular

weight and polydispersity of the monodisperse outer blocks. The complete

parameterization of these polymers enables quantitative comparisons with

theoretical predictions.

General

Synthetic Strategy. Our synthetic strategy

relies on well-known methods in chain transfer ring-opening metathesis

polymerization (ROMP-CT) to produce difunctional telechelic polymers with a

polydispersity Mw/Mn = 2.0. By installing functionalities at the chain ends

that enable the controlled/"living" polymerization of a second monomer,

ABA-triblock copolymers are readily produced in which the A end blocks are

monodisperse (Mw/Mn ² 1.15) and the center B block is

polydisperse (Scheme 1). Polymers derived from this methodology in which the

center block is poly(1,4-butadiene) from ROMP of 1,5-cyclooctadiene offer an

advantage over other systems of interest: selective degradation of the

polydisperse poly(1,4-butadiene) block enables direct analysis of the molecular

weight and polydispersity of the monodisperse outer blocks. The complete

parameterization of these polymers enables quantitative comparisons with

theoretical predictions.