Back to Table of Contents

46915-G5

In Situ Chemical Diagnostic Tribology of Dry and Lubricated Thin Film-Based Technologies

Thomas W. Scharf, University of North Texas

This

update focuses on research efforts to monitor real

time (in situ) wear, friction, and lubrication

(tribology) of solid lubricant thin films in dry and lubricated sliding

contacts. Little is known about how a liquid lubricant affects third body processes and

tribochemical (chemistry induced by sliding) reactions in situ, i.e. during sliding, especially when transitioning from a

dry to liquid contact. It is well known

that they contribute to tribological properties, but most studies are made ex situ, i.e. after the test, and

inferences are made about what occurred during the test. However, in situ optical

microscopy of the sliding interface is a more direct method for identifying

third body processes. Concomitantly,

micro Raman spectroscopy can be utilized as an in situ chemical tool to monitor tribochemical reactions and phases

that affect real time tribology.We have studied the transfer film (third body) behavior of a sapphire

slider on a tungsten-doped diamondlike (W-DLC) thin film when lubrication

changed from dry to lubricated sliding. The synthetic oil lubricant was Krytox, a

perfluoropolyether (PFPE)

fluid with applications to the petroleum industry. Figure 1 shows friction coefficients (mu)

vs. cycle curves (left: the run-in regime and right: the steady-state regime). The

“blue” curve in Figure 1 was taken with PFPE present from the beginning of

sliding and the “red” curve unlubricated.

With PFPE, mu dropped

immediately to 0.13; and, in dry air, the run-in mu remained high at ~0.6 for

about 25 cycles due to the inability to form a low friction transfer film. In

steady-state, mu in PFPE was

more than twice that in dry air, 0.13 vs.

0.05, respectively. The “black” curve

test will be discussed later.

Figure 1. Typical

friction coefficient (mu) vs. cycle curves for W-DLC thin film against sapphire

in dry air with PFPE in between, unlubricated out to 600 cycles then PFPE

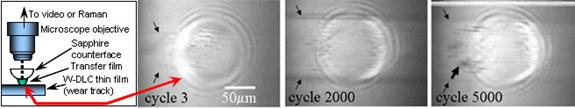

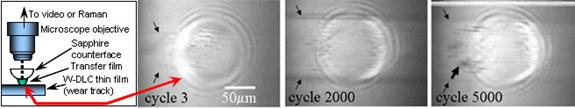

added, and unlubricated. In situ visual observations (setup in Figure 2) offered new

insights into the effect of liquid lubricants on transfer film retention and tribological

behavior. A careful viewing of the images

taken during the PFPE lubricated test detected very minimal thin film wear and

no transfer film formation. Figure 2

shows representative in situ optical

images at 3, 2000, and 5000 cycles. The

oblique-pointing arrows show how the wear track width increased by 50% from cycles 3 to 2000, but hardly

changed out to cycle 5000. However some

wear debris, probably from the W-DLC thin film, were generated as shown by the ‘thicker'

arrow in Figure 2 at cycle 5000. Sliding

appears to have been sustained by the lubricant with separation distance less

than that resolvable by the Newton's

rings (≤25nm). Thus, with PFPE the velocity accommodation relied on a thin

lubrication film whereas in dry air, the velocity accommodation mode was

interfacial sliding between a transfer film and thin film (wear track). Transfer film formation in dry air was confirmed

by the in situ Raman spectra (Figure 3) taken during the test from Figure

1, “red” curve. It is evident that both

the transfer film thickened and exhibited a tribochemical reaction

during sliding since there was an increase in carbon (D and G peaks) and WO3 intensities with

increasing sliding cycles, and the unworn coating

did not exhibit a WO3 phase and the carbon G-peak

shifted to higher wavenumbers characteristic of a sliding-induced graphitic transformation.

Figure 2. In

situ optical images of a sapphire counterface/W-DLC thin film interface taken

during sliding with PFPE lubricant in dry air.

The red arrow shows the position of the sliding contact at the buried

interface (sphere-on-flat geometry with Newton's

rings).

Figure 3. In

situ micro Raman spectra show an increase in carbon (D and G peaks) and WO3

intensities with increasing sliding cycles.

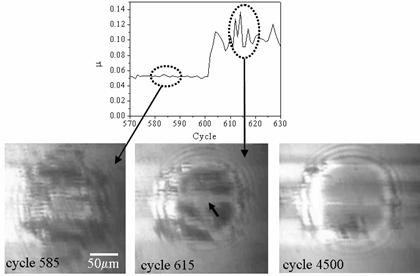

Figure

4 shows a more detailed view of the transition in mu, from the “black” curve test

shown in Figure 1 when PFPE was added at cycle 600. The friction coefficient increased

immediately from ~0.05 (cycle 600) to 0.11 (cycle 604), where it remained out

to cycle 5000. The accompanying in situ optical images at cycles 585, 615,

and 4500 show the evolution of the transfer film before and after PFPE was

added. The transfer film developed in

dry air (cycle 585) began to fall off by cycle 615 (see arrow); and with

further sliding out to 4500 cycles, most of the transfer film was lost. It is

likely that the PFPE, a low surface energy fluid, entered the film/sapphire

interface, displaced the transfer film, and then prevented third bodies from

adhering to the sapphire surface thereafter.

This suggests that liquid lubricants do not support low friction sliding

by transfer films.

Figure 4. Transition

in friction coefficient (mu) from dry to lubricated (PFPE) sliding with 3

accompanying in situ optical images of a sapphire/W-DLC thin film interface.

Back to top