Reports: ND755593-ND7: Mesoporous Polymer Frameworks by Architectural Control

Javid Rzayev, State University of New York at Buffalo

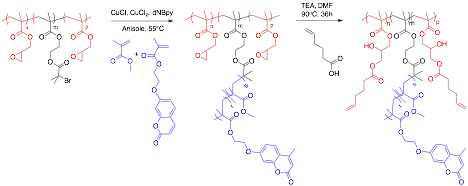

Reticulated nanoporous materials generated by versatile molecular framework approaches are limited to pore dimensions on the scale of the utilized rigid molecular building blocks (< 5 nm). The inherent flexibility of linear polymers precludes their utilization as long framework connectors for the extension of this strategy to larger length scales. We developed a new method for the fabrication of mesoporous polymer frameworks (MPF) by using bottlebrush copolymers with reactive end blocks serving as rigid macromolecular interconnectors with directional reactivity (Figure 1). End-reactive bottlebrush copolymers with pendant alkene functionalities were synthesized by a combination of controlled radical polymerization and polymer modification protocols (Figure 2).

Figure 1. Fabrication of mesoporous polymer frameworks from end-reactive bottlebrush copolymers.

Figure 2. Synthesis of orthogonally reactive bottlebrush copolymers with cross-linkable end blocks.

In order to investigate the efficiency of such a cross-linking strategy, we synthesized control bottlebrush copolymers with only one alkene-containing reactive end block and subjected them to Grubbs 3 catalyst to promote cross-linking via cross-metathesis. Near quantitative conversions (to brush-star polymers) were achieved within 5 hours at room temperature. Characterization by SEC-LS allowed us to determine that an average of 10 bottlebrush arms were present in every star molecule (isolated junction point). Subsequently, we investigated the formation of mesoporous polymer frameworks by using bottlebrush copolymers with two reactive ends

as rigid interconnectors. Ru-catalyzed cross-metathesis cross-linking of bottlebrush copolymers with two reactive end blocks resulted in the formation of polymer frameworks where isolated cross-linked domains were interconnected with bottlebrush copolymer bridges. Photo-cross-linking of bottlebrush copolymer side chains through coumarin dimerization provided additional reinforcement especially for longer connector networks. The generated polymer gels were robust enough to withstand simple solvent exchange and evaporation to produce mesoporous polymer frameworks whose structural characteristics were dictated by molecular dimensions of the bottlebrush copolymer precursors, allowing for rational materials design strategies. The obtained materials were characterized by scanning electron microscopy, nitrogen adsorption, and small angle x-ray scattering.

Pore dimensions of the synthesized MPFs were predictably manipulated by the choice of the bottlebrush connectors. Reticulated morphologies were evident in all samples irrespective of pore dimensions (Figure 3).

Figure 3. Scanning Electron microscopy analysis of a mesoporous material prepared from an end-reactive bottlebrush copolymer.

We used a three-dimensional correlation plot (Figure 4) between the size of bottlebrush side chains (y-axis), the length of the bottlebrush backbones (x-axis), and MPF pore diameter (marker size and shade) for networks prepared at the initial polymer concentration of 30 wt% to demonstrate pore size variation trends. Using longer bottlebrush connectors resulted in MPFs with larger pore diameters, which was a reliable way of controlling the mesh size of the bottlebrush networks. The obtained median pore diameters of 9-44 nm and onset pore diameters of 5-18 nm for these MPFs are consistent with the length of utilized bottlebrush connectors, where end-to-end distances of the hypothetically fully stretched bottlebrush backbones are in the range of 20-110 nm (representing maximum connector length). For four MPFs prepared from bottlebrush connectors with varying backbone lengths but relatively similar side chain length, the onset pore diameters appeared to scale linearly with the logarithm of the backbone length (d ~ logN). While physical meaning behind this simple empirical relationship is unclear, it provides a convenient handle for predictable materials design. Side chain length variation produced more nuanced effects on pore dimensions due to competition between opposing trends of bottlebrush connector stiffening with increasing side chain lengths and volume filling. For middle length connectors, this resulted in a modest increase in pore diameters with increased side chain dimensions. The ability to manipulate network dimensions by a simple molecular design not only affords a versatile materials design platform but also evidences controlled network buildup through end block interactions rather than random side chain cross-linking or some phase inversion process during solvent exchange.

Figure 4. Analysis of MPF pore dimensions prepared at initial 30 wt% polymer concentration: 3D correlation plot between bottlebrush side chain size (y-axis), bottlebrush backbone size (x-axis), and median BJH pore diameter (marker size and shade),

The materials fabrication strategy described in this work expands the length scale of molecular framework materials and provides access to mesoporous polymers with a molecularly tunable reticulated pore structure without the need for templating, sacrificial component etching, or supercritical fluid drying.