Reports: DNI955661-DNI9: The Fluid Mechanics of Channel Fracturing Technique

Sarah Hormozi, PhD, Ohio University

Summary and objectives:

In hydraulic fracturing, specially engineered suspensions are pumped at high pressure and rate into the reservoir, causing a propagating fracture to open. When the pressure is released the fracture is supported by the grains of solid proppant that are left behind. Recent trends in the oil industry have included the use of cyclic pumping of a proppant slurry interspersed with a yield stress fracturing fluid, which is found to increase the subsequent productivity. Therefore it is of interest to understand how slugs of proppant pumped in a cyclic fashion can disperse in the fracture. The objective of this project is to investigate the dispersion of solid in fracturing flows of yield stress fluid experimentally.

Accomplishments to date:

We developed a model framework able to include a wide range of fracturing flows from Stokesian to inertial and we showed that in relatively straight fractures and for fluids of moderate rheology, this framework simplifies into a one-dimensional model that predicts the solids concentration along a streamline within the fracture. This model showed that the leading order mechanism in dispersing the solid is the normal stress differences developed in the particle phase due to inhomogeneity of the shear stress in the fracture [1].

We then studied flows of suspensions of rigid spherical particles in a cylindrical Couette configuration with a Newtonian suspending fluid at a very low Reynolds number. We have used both Particle Tracking Velocimetry (PTV) and Particle Image Velocimetry (PIV) to examine the solid volume fraction and velocity field respectively. The experiments are carried out for a wide range of solid volume fractions (i.e., from dilute to dense suspensions). The results showed that particles disperse toward the outer wall of the cylinder, where a strong layering of particles occurs due to the confinement effects. We observe this phenomenon for bulk volume fractions beyond 20% and presented the comparison of both transient and steady state results with the continuum model frameworks that we developed in the first step [2].

Several challenges exist in moving toward a yield stress suspending fluid and performing an experimental study in fracture geometry to investigate the solid dispersion. Experimental techniques such as PTV requires a perfect matching of refractive index of the fluid and particles, therefore PTV comes short in studying opaque suspensions. When optical access is limited, there have been several advances to visualize suspension flows and different methods such as ultrasonic spectrometry, Nuclear magnetic resonance (NMR), Magnetic resonance imaging (MRI), and X-ray tomography have been widely adopted. The ultrasonic spectrometry fails in giving reliable measurements for dense suspensions. Techniques such as MRI, NMR and X-ray tomography require a large number of scanning points for 2D and 3D flows and consequently a long time for data sampling. Therefore, it is not possible to make use of these techniques to study transient and nonlinear suspension flows, e.g., transient particulate flows of yield stress fluids.

We overcame the above limitations by first inventing a repulsion dominated soft matter with tunable yield stress, consistency and refractive index for both X-rays and visible lights. This invention allows us to overcome the challenge of optical obstruction and make use of techniques such as X-ray/CT scan and PIV/PTV in studying dense suspensions. Having access to such a model suspension we developed the following experimental systems to study fracturing flows of yield stress fluids.

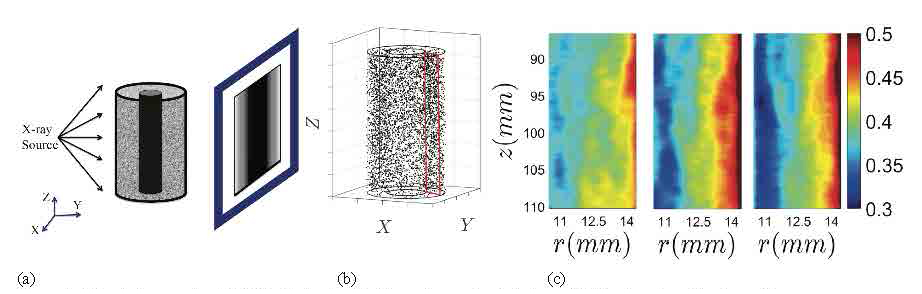

We established a new technique based on X-ray radiography with high temporal and spatial resolutions to study fast suspension flows regardless of optical access. In this method, we benefit from the axial symmetry of viscometric flows to extract a 3D solid volume fraction field from a single X-ray projection image. We propose a mathematical algorithm based on the inversion of Abel transform in conjunction with regularization and data denoising to measure the solid volume fraction field in suspensions in a fraction of a second. We show that the results are in excellent agreement with those obtained from micro Computed Tomography (CT scan) in several hours. This significant reduction in the data acquisition time opens a new avenue in the field of suspensions; particularly for fast suspension flows or those with source of nonlinearity such as yield stress suspending fluids. Currently, we are making use of this technique to study dispersion of solids in flows with yield stress fluids and in presence of shear inhomogeneity similar to what we have in fracturing flows [3], Fig. 1.

Figure 1: A typical example of SIM studied using the X-ray rheometry technique. (a) The Couette cell setup and X-ray source and detector. (b) CT scan of the flow field, dots show the location of particles. (c) 2D axisymmetric colormaps of solid volume fraction showing migration of particles from the inner cylinder to the outer cylinder at 3 different times (left to right) obtained via X-ray radiography.

We designed a channel that resembles a fracture with the following dimensions: 2mm width, 10 cm height and 4m long. This setup allows us to investigate the fracturing flows with similar geometrical and flow dimensionless numbers as in the real world but in a lab-scale setup. Currently we are making use of our transparent model suspensions and a well-resolved PIV/PTV technique developed in our lab to study the channel fracturing flows of yield stress fluids and examine and improve our model framework.

Impact of the project:

The model framework and techniques developed in the course of this project not only address the fluid mechanics of fracturing flows but also opens a new perspective in the field of complex suspensions [4]. The framework and experimental techniques are capable of studying dynamic systems with different sources of non-linearity such as suspension of non-colloidal particles in other non-Newtonian fluids. In addition, the skills and mathematical algorithms that we developed to analyze X-ray data go beyond the field of suspensions and are applicable in the field of advanced Cyberinfrastructure with the aim of advanced computing and analyzing data-intensive science and engineering research.

Journal publications to date:

[1] Hormozi, S. & Frigaard, I.A. Dispersion of solids in fracturing flows of yield stress. J. Fluid Mech., 830, 93-137, (2017).

[2] Sarabian, M., Firouznia, Metzger, B. & Hormozi, S. Dispersion of solid particles in

cylindrical Couette flows. Phys. Rev. Fluids, under review, (2017).

[3] Gholami, M., Lenoir, N., Ovarlez, G., & Hormozi, S. Time-resolved 2D concentration

maps in owing suspensions using X-ray. Journal of Rheology, under review (2017).

[4] Maleki, A., & Hormozi, S. Submerged jet mixing flows of municipal sludge mixtures. J. Non-Newtonian Fluid Mech. In press (2017).