Reports: DNI956386-DNI9: Pore-Resolving Simulations of Coal Char Gasification Using Micro-CT Imaging

Simcha L. Singer, PhD, Marquette University

Introduction

The goal of this study is to examine the impact of char particle morphology on gas transport and heterogeneous reaction during coal gasification. Because char particles contain a wide range of pore sizes, with the largest pores/voids often approaching the scale of the particles themselves, modeling char particles as effective porous media (an effective-continuum) is not appropriate. To understand the influence of these large pores/voids on the transport-reaction coupling during gasification, a pore-resolving simulation approach is employed. During the first year of funding, coal char particles have been characterized using X-ray micro computed tomography (micro-CT) and a reacting computational fluid dynamics (CFD) simulation has been developed to assess the impact of morphology on char particle gasification.

Methods

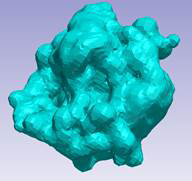

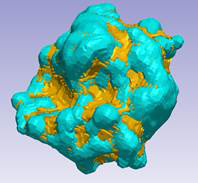

Illinois #6 bituminous coal was obtained from the Penn State coal sample bank and pyrolyzed in an electrically heated furnace to produce char particles. Micro-CT was used to resolve the internal and external structure of individual particles (Fig. 1(a)), followed by image processing and segmentation of the resolved pores/voids (orange) and the microporous solid regions (blue), shown in Fig. 1(b). The reconstructed char particle shown in Fig. 1 is used in the transient, three-dimensional CFD simulations for the results presented below.

Fig. 1. (a) A reconstructed char particle from micro-CT, (b) with microporous regions (blue) with resolved pores (orange) delineated.

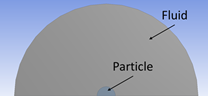

To study the impact of void morphology on gasification, two separate CFD models were developed: a three-dimensional, large pore/void-resolving model based on micro-CT imaging and a classical, spherically-symmetric, effective-continuum model. To ensure a valid comparison between the two models, the volume, mass, porosity, surface area and effective particle diameter were identical in both models. The particles were located at the center of a spherical domain with a diameter ten times that of the particles, as shown in Fig. 2. The boundary conditions represent an entrained flow gasification environment.

Fig. 2. Computational domain, including particle and surrounding gas.

The pore-resolving CFD model employs conservation equations based on first principles for mass, momentum, species and energy in the resolved pores/voids, and upscaled, effective-continuum equations only in the micro-porous regions, where such equations are appropriate. The spherically-symmetric model employs upscaled, effective-continuum equations throughout the entire particle. Following a mesh convergence study, CFD results from the two models were compared.

Results

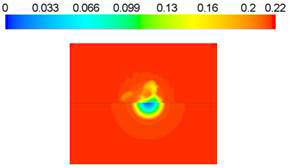

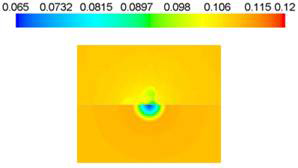

Profiles of gasifying agents H2O and CO2 at a relatively early stage in the gasification process, when intra-particle species gradients are present, are shown in Fig. 3. Both models show minimum reactant concentrations at the center of the particles, as expected, although the pore-resolved model exhibits less severe species gradients than the analogous effective-continuum model, because the resolved large pores not captured in effective-continuum approaches facilitate enhanced reactant transport.

Fig. 3. Pore-resolving (top) and effective-continuum (bottom) contours of reactant mole fraction at 50 ms for (a) H2O, and (b) CO2.

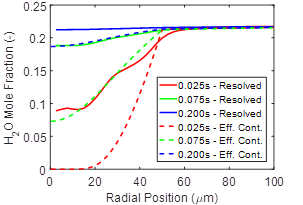

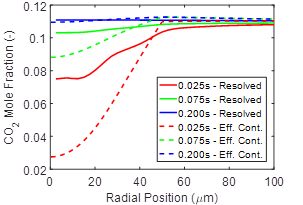

To quantify the effects of the resolved pores, polar and azimuthally-averaged species profiles at each radial position for the three-dimensional model are compared to the spherical, effective-continuum model. Figure 4 shows comparisons at several times for a 50 μm radius particle, for both reactants, and indicates that species transport limitations are over-predicted by the effective-continuum model until ~200 ms, at which time the gasification regime transitions from zone II (intra-particle diffusion limitations) to zone I (kinetically limited). Because diffusion limitations are more significant for the faster steam gasification reaction than the CO2 gasification reaction, the difference between the modeling approaches is more pronounced for H2O than CO2.

Fig. 4. Polar and azimuthally-averaged reactant mole fractions as a function of radius for (a) H2O, and (b) CO2.

Impact of research

A manuscript describing the micro-CT-based pore-resolving simulation approach is in preparation. The next year will be devoted to application of the modeling approach to many particles to obtain a statistically significant comparison between pore-resolved and effective-continuum models. Using results from the pore-resolved simulation, modifications to increase the fidelity of simpler, computationally inexpensive models will also be explored.

The research funding provided by the ACS Petroleum Research Fund enabled the PI to pursue a new research approach with promise for a variety of solid fuel applications. The funding also enabled the PI to increase the size of his research group and was used to support a graduate student during the first year of the project. The student became proficient in performing CFD simulations and obtained a Master’s degree this summer.