Reports: ND956353-ND9: Effect of Contact Forces on Displacement of Immiscible Fluids through a Porous Network

Ellen K. Longmire, University of Minnesota

The goal of this project is to investigate the effect of sharp geometries on the propagation of an immiscible liquid interface through a porous medium. This topic is fundamental to understand the dynamics and transport of multiphase flow through porous rocks with applications to enhanced oil recovery, its modelling, and its simulation. We want to address the following questions: how does the pore geometry affect the contact forces and the streamwise propagation of the liquid-liquid interface? What is the impact of sharp vs. round edges on the residual oil saturation in the porous medium? During the first year of the grant, two experimental problems have been considered: flow through a porous network with sharp and rounded edges, and the penetration of falling spheres, smooth and spiky, through an oil-water interface.

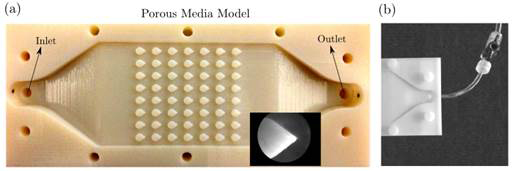

To investigate the effect of geometry in the porous media flow, we designed and fabricated the quasi-two dimensional network depicted in figure 1a. The model was 3D-printed using opaque VeroWhitePlus (RGD835) from Stratasys© in the Medical Devices Center of the University of Minnesota.

Figure 1. Porous media geometry. a) Top view of the network manufactured by 3D printing. The insert is a microscope view of one obstacle presenting the sharp edge. b) Process to remove residual bubbles by the use of bleed points near the inlet/outlets.

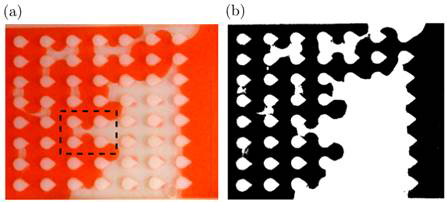

The inlet and outlet cross-sections are located symmetrically in the geometry allowing investigation of flow in either direction and evaluation of the impact of sharp and round edges on the contact forces during flow displacement. A microscope picture of one obstacle highlights the sharp edge of the tear drop forms which have radius of curvature ~0.2 mm. The model is covered with a rigid acrylic plate flush to each obstacle and clamped using multiple screws. The interior of the model is initially filled with silicone oil, and residual air bubbles are removed through bleed holes connected to on/off valves (see figure 1.b). The silicone oil is subsequently displaced by an aqueous solution using a syringe pump with calibrated flow rate. A snapshot of the porous network during the withdrawal of oil (white) by injecting dyed water (red) is shown in figure 2.a, where the flow is left to right.

Figure 2. a) Snapshot of the displacement of silicone oil 20 cst (white) by dyed water (red). b) Residual oil (white) trapped between the porous obstacles. The flow is from left to right.

In the flow picture, we note the advancement of multiple menisci along the streamwise and lateral directions. There is a preferential flow path in the upper part of the network which causes an asymmetric distribution of both fluid phases. Oil-bridges also form upstream of the interface front. This residual oil remains trapped in the porous network (white area in figure 2.b) and is formed by the lateral advancement and coalescence of water (red), as exemplified by the dashed area in the figure. The residual oil saturation and the dynamics of the front propagation depend critically on the Capillary number (Ca) of the flow. By adjusting the flow rate using a syringe pump, we are able to analyze the effect of sharp edges for a wide range of Ca and viscosity ratio of both liquids.

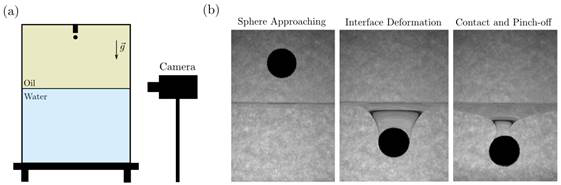

Separate experiments were performed to study the motion of smooth and rough spheres falling onto a flat oil-water interface. This auxiliary configuration will help us to identify the effect of surface irregularities on a more simplified 3D geometry. The experiments were performed by Luuk Altenburg (Visiting Student from TU Delft, Netherlands) and Diogo Barros (Postdoctoral Associate, University of Minnesota). A sketch of the apparatus is presented in figure 3.a, where the oil-water interface is created inside an acrylic tank.

Figure 3. Motion of a sphere through an oil-water interface. a) Sketch of the experimental apparatus. b) Steps during the falling of a rough sphere through the interface captured by a high-speed camera.

After release at the top of the oil domain, the sphere settles under gravity, deforms the interface, and continues to sink for certain parameter combinations (see figure 3.b). The dynamics of this process has been investigated over Bond numbers (computed using liquid-liquid density difference and sphere radius) in the range 0.2-1.05 and fluid-fluid viscosity ratios of 0.05-15. The ratio of solid-oil to water-oil density difference varied over 1.6-21. The influence of inertia in the problem is also considered by releasing spheres from multiple heights to account for variable approach Weber and Reynolds numbers up to 26 and 174 respectively. We have acquired comprehensive data sets over these ranges and are currently analysing the results.

In the coming year, we will complete parametric tests with the porous media model to draw a general picture of the effects of geometry on the immiscible liquid displacement. We also plan to fabricate and test additional network configurations, e.g. using square obstacles and irregular obstacles, to compare the imbibition and drainage flow mechanisms to the existing phenomenology in the literature. These experiments will provide key ingredients for future models of multiphase flow in porous media accounting for geometrical features. While our investigation is still very much in progress, it is making significant impacts on the careers of the post-doc and student who have participated thus far. Dr. Diogo Barros has been able to broaden his research expertise into a new and interesting direction. For Luuk Altenburg, who participated as an ‘intern’ from TU Delft, the work on falling particles is forming the basis of his master’s thesis and helping initiate a broader collaboration between University of Minnesota and TU Delft.