Reports: ND955700-ND9: Electrohydrodynamic Atomization of Fuels Using Charge-Injection for Efficient Flameless Catalytic Combustion at Small Scale

Paul R. Chiarot, PhD, State University of New York at Binghamton

Project Summary

Flameless catalytic combustion of petroleum-based fuels inside miniaturized systems is a new paradigm in portable power generation. The most promising fuels for portable applications are those with the highest energy density. However, these fuels are often the most difficult to vaporize and mix with the oxidant. We are exploring the use of electrohydrodynamic (EHD) atomization to vaporize and mix energy dense, liquid fuels. We seek to achieve efficient atomization without the need for fuel additives and to use secondary electric fields to shape the emitted droplet plume.

Research Progress and Results

We have made excellent progress on the goals of this project and the testing of our two original hypotheses. In Year-1, we completed the construction of our test fixture. This fixture provides control over all the relevant parameters associated with EHD atomization (pressure, flow, potential) and the ability to fully characterize the emitted fuel (high speed imaging, electric currents, products of combustion). As per hypothesis #1, we have successfully used EHD to atomize energy dense single and multi (i.e. diesel) component fuels without the addition of additives. As per hypothesis #2, we have shown that external effects can influence atomization; in particular jet breakup and the geometry of the plume. Our results were reported at the Institute for Liquid Atomization and Spray Systems in 2017.

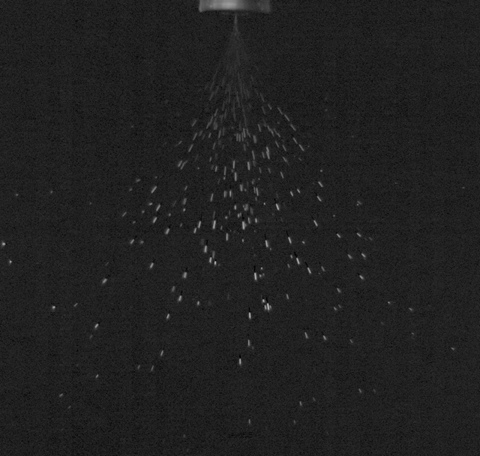

For EHD atomization, we have discovered three (spatial) regions that are significant for jet-to-droplet transition. In the first region, close to the emitting orifice, the jet undergoes a bending instability that assumes a helical shape and rotates with a clockwise sense (Figure 1). We are working to determine the physical mechanisms that cause the helical jet and its rotation direction. We have posed a new hypothesis that the electric current in the jet induces a magnetic field that biases the motion of the (bending) jet in the clockwise sense. The direction of the rotation is determined by the magnetic field, while the actual bending of the jet is driven by electrostatics. The second region is the domain where the jet breaks up (Figure 2). We are characterizing the droplet generation mechanisms, the droplet size distributions, and the droplet charge distributions. Our hypothesis is that the droplet generation regime and the droplet characteristics are predominantly governed by the charge density in the jet while the droplet size and charge distributions are predominantly governed by the charge density and the initial diameter of the jet. The final region covers the structure of the spray plume (Figure 3). Here, we seek to discover the forces and droplet-droplet interactions that dictate the spray plume structure. We contend that the spray plume structure is not predominantly governed by electrostatic repulsion, as in electrospray, or jet momentum and aerodynamic shear forces, as in traditional fuel injection. Rather, the spray plume structure results from a combination of electrostatic repulsion and tangential momentum induced by the bending instability.

We have established a new collaboration with colleagues in the Department of Chemistry at SUNY Binghamton who conduct research on low-temperature catalytic combustors. Our EHD atomization technique will supply energy-dense fuels to their combustion system. We propose to discover how the atomization parameters govern the combustion efficiency. For example, we will use the new knowledge created by our research to produce the smallest possible droplets, which we expect will offer the best performance.

Impact of this Research

The combustion of petroleum-based fuels inside miniaturized systems will have a major impact on portable power generation. The energy output from these systems has the potential to far exceed advanced lithium ion battery technology. Direct conversion of heat into electrical energy is possible using a new class of modern thermoelectric materials. The most promising fuels for portable applications are those with the highest energy density. However, these fuels are often the most difficult to vaporize and mix with the oxidant. Incomplete vaporization leads to poor combustion performance and the production of hazardous reaction products. This is especially a problem for miniaturized systems given the limited size of the combustion chamber. This research is creating new knowledge on the EHD atomization of fuels to address these issues. Applying this new knowledge will support the creation of a new, compact energy source based on the use of readily available fuels.

This project provides financial support for a PhD student and an undergraduate student in Mechanical Engineering at SUNY Binghamton. The highly interdisciplinary nature of this project - combining fluid mechanics, heat transfer, chemistry, and combustion engineering – is an excellent educational opportunity for these students. This research is preparing them for a future career focused on new technologies related to combustion.

Research Plan for Project Year 3 (NCE Year)

Through this research, we have discovered that the physics associated with EHD atomization is much richer and more complex than pressure based systems. To be used efficiently in combustion applications, the relationship between processing parameters and the droplet characteristics (size, distribution, etc.) must be established. Our plan is to continue working with fuels to create new knowledge on the methods of droplet generation during EHD atomization. We have posed new hypotheses related to the jet and plume dynamics and have devised a set of experiments to test them. Further to hypothesis #2 from the original proposal, our plan is to discover how secondary electric fields can be used to shape the droplet plume and potentially drive different modes of atomization. Working with our collaborator at SUNY Binghamton, we will test the efficiency of our atomization technique using low-temperature catalytic combustion.

Figure 1: Micrograph of Region #1 close to the emitting orifice. Initial jet diameter is 200 µm and the applied potential is 4.5 kV.

Figure 2: Micrograph of Region #2 where the charged jet breaks up. Initial jet diameter is 200 µm and the applied potential is 4.5 kV.

Figure 3: Micrograph of Region #3 showing the droplet plume structure. Applied potential is 5.0 kV. Fluid is diesel fuel.