Reports: ND1055860-ND10: Impact Fatigue Behavior of WC-Co Cemented Carbides: Microstructure and Stress Wave Interactions

Leslie Elise Lamberson, PhD, Drexel University

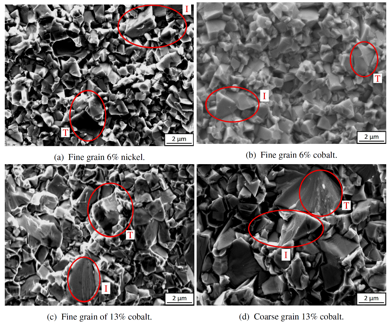

Four different grades of tungsten carbide (WC) were examined for this project. These included three grades of cobalt bound WC and one Ni bound WC. Cobalt based grades include a 6% fine grain (WC-F6Co) and a 13% fine and coarse grain (WC-F13Co, and WC-C13Co respectively). The nickel based material was fine grain at 6% (WC-F6Ni). The designations of fine and coarse came from the manufacturer (General Carbide), listing a 1-2 µm average grain size for fine grain, and 3.5-5 µm grain size for course. The average grain size was measured in-house via SEM as being 0.8-1.3 µm and 1.0-2.5 µm, respectively.

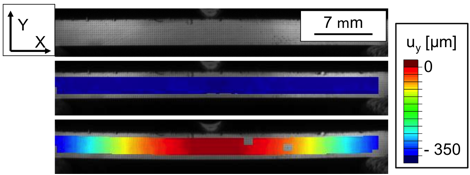

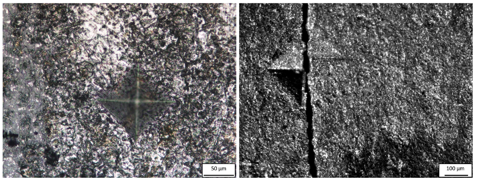

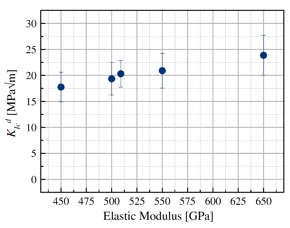

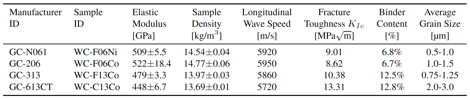

As a baseline before any dynamic investigations, flexural tests, which were used to extract the elastic modulus utilizing Digital Image Correlation (DIC) mapping the local displacements (Figure 1), and quasi-static fracture tests in three-point bend were carried out on all grades. An example of the indentation and resulting fracture from the quasi-static three-point-bend experiments is shown in Figure 2. Generally, as the binder content increased, the quasi-static fracture toughness also increased with a decrease in the elastic modulus (which corroborates similar results in literature), as shown for WC-F6Ni in Figure 3.

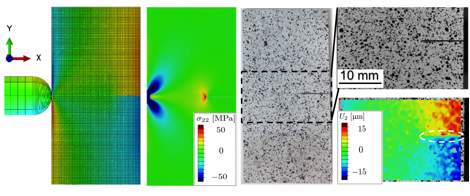

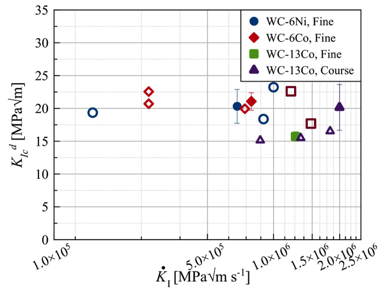

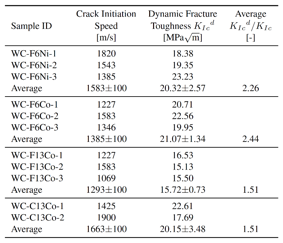

The first year dynamic efforts focused on single strike to failure of single edge notch samples and including FE modeling to tailor the waves and geometry (Fig. 4). The results revealed that grades of WC that have greater binder contents also had higher dynamic fracture toughness values (perhaps unsurprisingly as it followed known behavior under quasi-static loading conditions). It should be noted however, that a quantitative characterization of dynamic fracture as a function of binder type and amount in WC hardmentals had never previously been reported in literature (until this project). This effort culminated in a published paper as part of a Special Edition of International Journal of Fracture.[1] The details of both the quasi-static testing and dynamic testing are provided in Tables 1 and 2. The newly generated surfaces resulting from the fracture testing were studied with SEM. Figure 5 shows intergranular and transgranular fractography, and Figure 6 shows the rate dependent response.

The second and final year research focused on characterizing the mode-I or opening dynamic fracture toughness of WC plates that have been subjected to a series of low-velocity impact cycles prior to instigating full fracture at higher velocity; thus probing impact fatigue behavior and its influence on catastrophic fracture in WC hardmetals. The goal here is to shed light on understanding how sub-critical impacts effect the overall crack tip intrinsic toughening mechanisms, essentially blunting effects, largely driven by the binder.

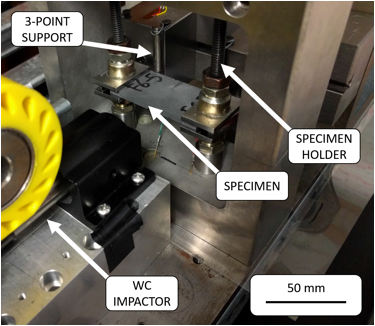

Two grades of WC with fine cobalt binders were examined, 6% and 13%, under impact fatigue conditions. Samples were identical in impact fatigue and dynamic fracture cases of 60x30x4 mm with a 10 mm edge notch cut via electrical discharge machining (EDM), and further sharpened with a razor blade and diamond paste for pre-cracking.

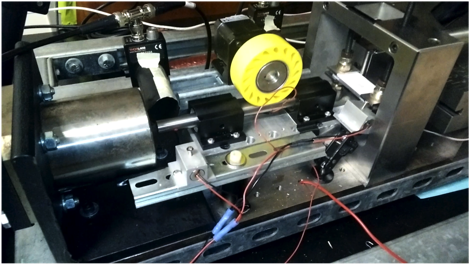

Repetitive loading was performed using an impact fatigue device that was designed, built and validated by the PI (Fig. 7 and 8). The device launches a 190 mm long and 13.4 mm diameter WC striker at 0.5 m/s at a rate of 0.2 Hz. Kinetic energy of 0.07 J is provided with each strike into the plate. The plates have been impact fatigued at 1000, 10000, and 50000 cycles (R=-1), for an accumulated kinetic energy of approximately 70, 695, and 3470 J prior to the testing under a higher velocity impact (that matches the first year fracture investigations) to instigate full fracture. The corresponding dynamic stress intensity factor at crack initiation (dynamic fracture toughness) will be compared for these three pre-cycled cases of the two levels of binder content. These efforts are presently being completed, and a paper describing the impact fatigue and fracture results is planned for submission at the end of November.

The PI and graduate students are grateful for the support provided by the ACS-ND grant.

Figure 1: Quasi-static flexural test in 3-point bend WC hardmetal example, used to extract the elastic modulus using in-situ deformation mapping via digital image correlation (DIC).

Figure 2: Example of Vickers indent and resulting fracture from quasi-static 3-point bend test.

Figure 3: Sensitivity of the extracted dynamic stress intensity factor to variations in elastic modulus for WC-F6Ni.

Figure 4: Discretized FE model showing stress build up from impact and resulting experimental field of view of crack tip displacements from dynamic loading.

Figure 5: SEM images of the dynamic fracture surface of representative samples from each grade of tungsten carbide, showing mostly intergranular fracture path taken through the viewable area. Images (a, b, c) show fine grain samples, with notably less visible binder, while (d) shows a coarse grain sample, with significantly notable binder visible, showing areas of approximately 2 micron regions of binder between the grains. In each image, the callouts indicate the presence of both intergranular and transgranular cracking, designated by "I" and "T" respectively.

Figure 6: Dynamic critical stress intensity factor as a function of fracture loading rate for WC hardmetals.

Figure 7: General view of unique impact fatigue device in lab.

Figure 8: Zoomed in view of the impact fatigue device, showing WC sample held in place against a 3-point roller support.

Table 1: Microstructural and mechanical characterization of tungsten carbide hardmetals from SEM and quasi-static experiments. The longitudinal wave speed is calculated from 1D wave mechanics, using the measured elastic modulus and density of the material.

Table 2: Dynamic fracture toughness experimental results for four grades of WC-Co/Ni.

[1] P. Jewell, L. Shannahan, R. DeMott, M. Taheri, L. Lamberson, Rate and Microstructure Inuence on the Fracture Behavior of Cemented Carbides WC-Co and WC-Ni, International Journal of Fracture, invited Special Edition, (2017): 1-17.