Reports: ND956921-ND9: A Computational Fluid Dynamics Study of Micro-Emulsion Formation and Transport in a Porous Media

Thomas Ward, PhD, Iowa State University

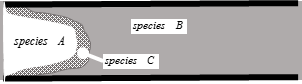

This research seeks to perform a computational study to develop methods that improve sweep efficiencies through chemically enhanced recovery of oils from the porous media that make up most land-based oil wells. The PI is considering the micro-rheological behavior of a micro-emulsion that spontaneously forms at the interface separating two nearly miscible liquids in order to develop a firm understanding of these type of displacements which are relevant to the efficient removal of oil from porous media. The porous media is modelled using a two or three dimensional channel or axisymmetric tube geometry. The term chemically enhanced is a generic phrase used to denote an aqueous phase that contains surfactants, solvents and/or possibly alkaline salts that are used to reduce the interface tension between it and an oil such that the two species can be considered miscible. We are particularly interested in what happens at the oil/water interface in the presence of surfactants or surfactant producing chemical reactions. The reason is that at the interface a micro-emulsion can form which has physical properties that are vastly different from either continuous phase fluid. In terms of modelling, the micro-emulsion can be considered a third species with its own physical properties. A schematic of the setup appears below.

To solve the problem mathematically the PI has focused on a three species conservation equation model written as:

for

the case of two miscible species where micro-emulsion formation occurs at the

interface. The subscript ![]() is used to denote the species A, B or C. The variable

is used to denote the species A, B or C. The variable ![]() is used to denote the diffusivity

of species C, in A and

B. The variable

is used to denote the diffusivity

of species C, in A and

B. The variable ![]() is the reaction rate, and is not necessarily a

chemical reaction rate but rather a rate at which the interface is emulsified.

We still relate the reaction rate to the production/consumption using a rate

constant, k.

is the reaction rate, and is not necessarily a

chemical reaction rate but rather a rate at which the interface is emulsified.

We still relate the reaction rate to the production/consumption using a rate

constant, k.

The species conservation equations are coupled to the momentum and mass conservation equations,

and

The stress term is written:

The dimensionless form of the transport equations yield a minimum of three operating parameters: The Reynolds, Peclet and Damkohler numbers:

where ![]() and

and ![]() are the tube diameter and inlet

velocity respectively.

are the tube diameter and inlet

velocity respectively. ![]() is a reference viscosity taken as the oil phase in

the simulations.

is a reference viscosity taken as the oil phase in

the simulations.

In the first year of the grant the PI has focused on the development of robust shear viscosity models for the emulsion. Incomplete studies of these types of system currently appear in the literature, and the PI is planning to publish a paper within the next year of the grant to help fill this gap. Currently, shear viscosity measurements within the PIs group are performed varying:

1. Shear rate, and

2. Water-Alkaline/oil concentration.

Viscosity is measured using a viscometer in the PI’s lab, manufactured by Black Pearl. All measurements are made using cup-and-bob type viscometry tools. The two fluids are initially unmixed in the viscometer cup. Then, as the two fluids are sheared by the bob an emulsion forms and we measure the viscosity. In this configuration the drop size is not constant so there is the potential for large variations in the measurements but we believe this setup is closer to what actually occurs for in-situ emulsification.

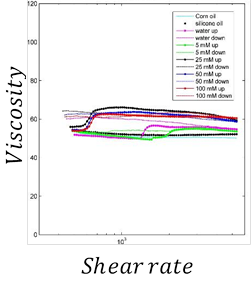

Below is a plot showing a small selection of the total data collected. The viscosity is measured as a function of shear rate for initially unmixed water and corn oil concentration fixed at 20:80 while varying the sodium hydroxide concentration between 0, 5, 25, 50 and 100 mM.

Note that the viscosity increases for all cases as the shear rate increases. Also notice that the shear rate where the viscosity increases is dependent on the sodium hydroxide concentration. We believe this suggests that the pore diameter is critical in enhancing sweep efficiency.

In order to properly model this behavior we need a shear rate dependent viscosity model. A model that can predict both of the plateaus in the data shown above is the Carreau model where

The Carreau model is excellent for modelling viscosity over a wide range of shear rates since it has limiting values for high and low shear rates.

The funds from the ACS-PRF have had a positive effect on the PIs research goals thus far. With these funds we have been able to focus attention on the underlying physicochemical phenomena associated with chemically enhanced fluid recovery. We believe that the work will result in important contributions to this field that will be beneficial to others studying similar problems.

The funds have also had a positive impact for the PIs research group. We have been able to expand and have added another graduate student to this project (previously there was only one graduate student). And we are especially happy to say that the student is a woman, so we are increasing the number of students from underrepresented groups who are exposed to research.

To conclude it is necessary to mention one of the overall, but maybe underappreciated goals of the research. There are practical benefits to increasing sweep efficiency. Since water is typically used as the displacing fluid, mainly because of its perceived abundance, then improving sweep efficiencies can also reduce its usage.

We would like to thank and acknowledge the ACS and PRF for the funds.