Reports: UNI655151-UNI6: Investigating the Development of Intermolecular Networks in Coatings with Single-Sided NMR

Tyler Meldrum, College of William and Mary

The curing of coatings is a phenomenon with an interesting and complex mechanism, from molecular cross-linking to the formation of a molecular network over time ranging from seconds to days. Some studies have looked at spatial changes in the thickness of an applied coating during the curing process, while others have examined molecular changes via optical spectroscopies. However, none has adequately addressed the formation of the intermolecular network during the curing process. The proposed research concerned the investigation of coatings during the curing process using single-sided NMR. Such NMR experiments, like many done previously, can probe the total thickness of an applied coating, reporting on the rate of solvent evaporation. However, single-sided NMR can also measure relaxation times—measurements that are indicative of the spatial arrangement, and thus network, of molecules within the film. These measurements can be made in a spatially sensitive manner, tracking changes throughout the thickness of a coating, with high spatial resolution. Using the proposed methods, coatings with different compositions can be compared under different environmental conditions and on different substrates. As anticipated at the outset of this project, improving our understanding of the effect these parameters have on the curing process may help to control the final properties of the coatings, perhaps by tuning the conditions of curing to achieve an optimal result, as well as to suggest ways to facilitate later removal of the coating, should that need arise.

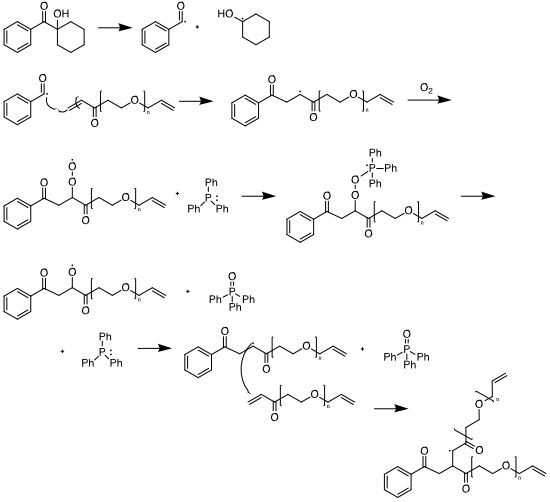

Figure 1. Scheme depicting the UV-initiated curing of a poly(ethylene glycol) diacrylate (PEGDA) coating using 1-hydroxycyclohexyl phenyl ketone (HPCK) as the photoinitiator. Triphenylphosphine (PPh3) mitigates the effect of atmospheric oxygen on disrupting the crosslinked network.

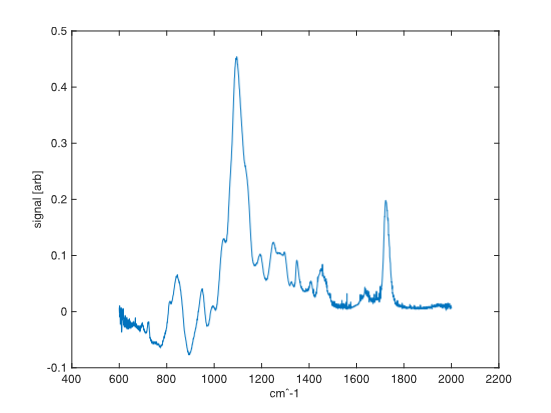

We studied a UV-curable coating, poly(ethylene glycol) diacrylate (PEGDA) with the photoinitiator 1-hydroxycyclohexyl phenyl ketone (HPCK); the mechanism for this curing process is shown in Figure 1. This system is well documented and requires only commercially available chemicals. To achieve consistent results, we designed and 3D-printed a spin coater that was driven by a disused hard drive and allowed for simultaneous spinning and UV curing. (See Figure 2.) After spinning, FTIR measurements confirmed the extent of curing (Figure 3), and were followed by NMR measurements.

Figure 2. Schematic (top) and final product (bottom) of a 3D-printed spin coater assembly driven using a disused hard drive. This spin coater was designed to facilitate UV-curing during the spinning process, in an attempt to avoid spatial inhomogeneities of UV intensity.

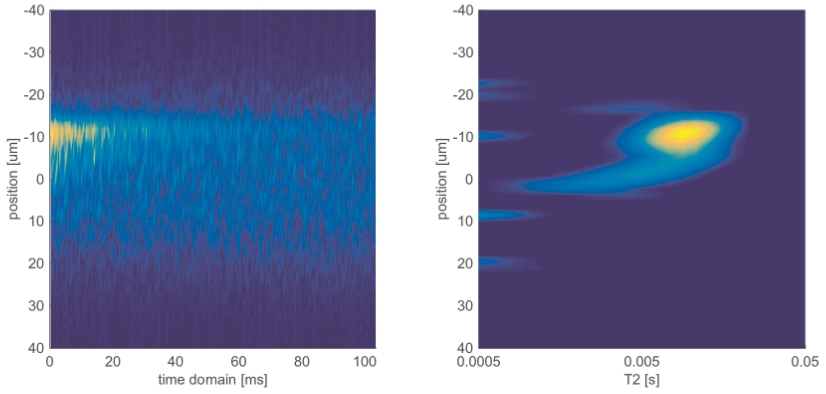

Our NMR measurements revealed a largely consistent relationship between the degree of curing and the spin-spin relaxation time T2: as the extent of curing increases, relaxation times decrease. More interestingly is a method of data processing that we developed during the course of this project to represent the relaxation times in a spatially-sensitive manner. In this way, was can see whether cross-linking occurs uniformly throughout the thickness of the film, or whether “skin effects” create regions of greater/lesser cross-linking. See Figure 4 for a depiction of this method. We verified this approach with samples that had triphenylphosphine (PPh3) added, an antioxidant that prevents the formation of skins on films that are cured in an oxygen-containing atmosphere.

Figure 3. ATR-FTIR spectrum of the cured PEGDA/HCPK coating.

Figure 4. An example of the data visualization method developed during the project. The left figure represents the position of the sample (vertical axis) vs. the signal decay as a function of the NMR measurement of T2 (horizontal axis). By subjecting each position point to an appropriate mathematical transformation, a position-sensitive plot of relaxation times T2 is generated (right). This plot shows the extent of crosslinking (larger T2 values are less crosslinked) as a function of position throughout the coating. The spatial resolution is on the order of 1 μm.