Reports: UR755468-UR7: Petroleum-Based Epoxy Mirrors with Optically Smooth Surfaces

K. Lisa Brodhacker, PhD, Lander University

For the summer of 2017, this grant was able to fund three undergraduate students (figures 1-4): two part time and one full time. In addition, one student worked on the project but was funded by a different source so we had a productive three months. Fortunately, our university was able to purchase a new Dynamic Mechanical Analyzer, which was installed and ready by May. This enhanced our research greatly because we were able to test samples in house.

Figures 1-4 (l to r): Jason Lee synthesized functionalized iron-, cobalt- and nickel oxide nanoparticles; Payton Rogers is seen here with our new DMA; Blair Harmon made and tested epoxy samples with various additives; Jordan Bates functionalized silicon oxide nanoparticles.

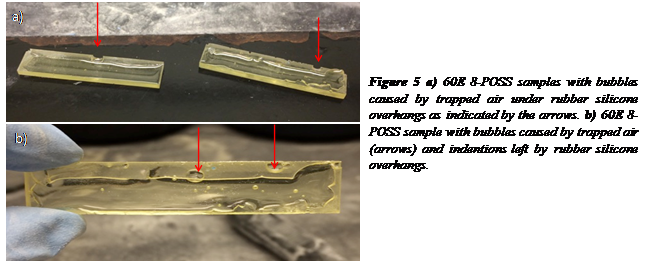

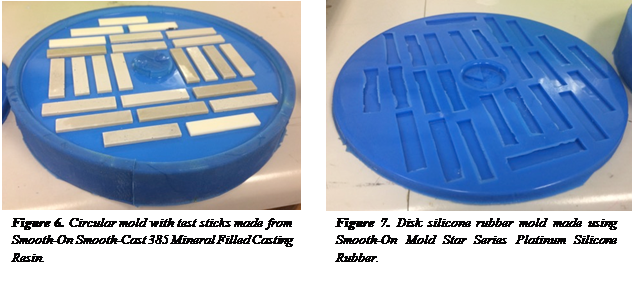

Various additives are utilized in our research to lower the coefficient of thermal expansion and to raise the modulus of the epoxy mixture. In the last narrative I reported that a student prepared samples with 5, 10, 15 and 20% functionalized polyhedral oligomeric silsesquioxanes as well as samples with 1 and 3% multi-walled carbon nanotubes. These were tested for CTE but we could not test for the modulus. Unfortunately a few of the samples had bubbles due to the mold we were using (see figure 5). So the first order of business this summer was to prepare a new mold. Once the mold was in place (see figure 6) and shown to be successful, some samples were prepared again and testing began. With 54 variations of epoxy formulations and additive percentages we will have much data. The testing will continue throughout the fall semester.

|

Figure 5 a) 60E 8-POSS samples with bubbles caused by trapped air under rubber silicone overhangs as indicated by the arrows. b) 60E 8-POSS sample with bubbles caused by trapped air (arrows) and indentions left by rubber silicone overhangs. |

|

Figure 6. Circular mold with test sticks made from Smooth-On Smooth-Cast 385 Mineral Filled Casting Resin. |

|

Figure 7. Disk silicone rubber mold made using Smooth-On Mold Star Series Platinum Silicone Rubber. |

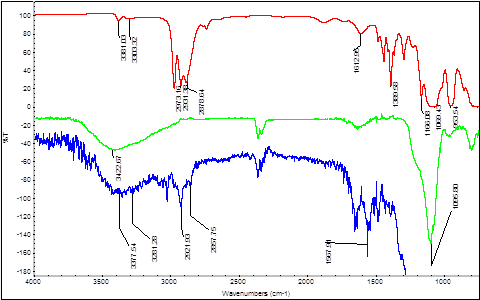

Another additive that we investigated this summer was silicon oxide. A student first functionalized off-the-shelf silicon oxide nanoparticles of varying sizes (8 nm, 15 nm and 60 nm; we also compared porous silicon oxide nanoparticles of 15 nm size to non-porous). The amino functionalization was confirmed with IR spectroscopy (see figure 8) and samples with varying percentages of functionalized silicone oxide nanoparticles were prepared. We are currently testing the CTE, Tg and modulus of all the samples.

Figure 8. Stacked IR spectra of APTES in red, plain silica in green, and functionalized silica in blue. The hydroxyl groups for the plain silica are present as shown by the OH peak at 3422. The functionalization was complete and confirmed by a shifting of that peak upfield and the appearance of the C-H peak at 2921.

Finally, we made more progress on the magnetic shape memory polymer. Iron oxide was once again synthesized and functionalized along with cobalt oxide and nickel oxide. Flat mirror samples were made with both functionalized and unfunctionalzed particles (see figure 9). These have been sent to Gravic labs in Pennsylvania where they will undergo testing.

Figure 9. Flat mirrors containing cobalt oxide, nickel oxide and iron oxide magnetic nanoparticles have been prepared and will soon be tested for their magnetic response to an external stimulus. It appears the cobalt oxide and nickel oxide may not have a strong enough magnetic pull to move the mirror. We are now looking into gadolinium oxide nanoparticles.