Reports: DNI1055570-DNI10: A Novel Microtubular Mesoporous Carbon Catalyst Support

Jiahua Zhu, PhD, The University of Akron

PROGRESS REPORT

With the support of ACS PRF, significant research progress has been made over the past year focusing on the topic of biomass processing into functional materials including but not limited to catalyst support. By completing the first-year goal, additional efforts were devoted to explore other related research areas as well. The research progress is summarized as follow.

(1) Biomass carbon in environmental adsorption and electrochemical energy storage

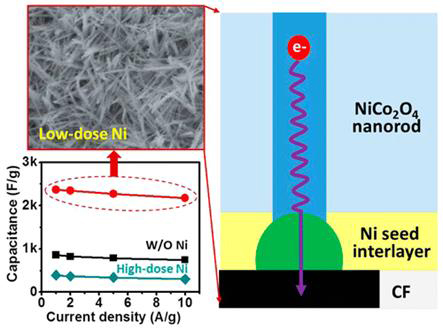

Figure 1. Pore size dependent molecular adsorption of cationic dye in biomass derived hierarchically porous carbon.

Hierarchically porous carbon adsorbents were successfully fabricated from different biomass resources (softwood, hardwood, bamboo and cotton) by a facile two-step process, i.e. carbonization in nitrogen and thermal oxidation in air. Without involving any toxic/corrosive chemicals, large surface area of up to 890 m2/g was achieved, which is comparable to commercial activated carbon. The porous carbons with various surface area and pore size were used as adsorbents to investigate the pore size dependent adsorption phenomenon. Based on the density functional theory, effective (E-SSA) and ineffective surface area (InE-SSA) was calculated considering the geometry of used probing adsorbate. It was revealed that the adsorption capacity strongly depends on E-SSA instead of total surface area. Moreover, a regression model was developed to quantify the adsorption capacities contributed from E-SSA and InE-SSA, respectively. Revealing the pore size dependent adsorption behavior in biomass derived porous carbon adsorbents will help to design more effective materials (either from biomass or other carbon resources) targeting to specific adsorption applications.

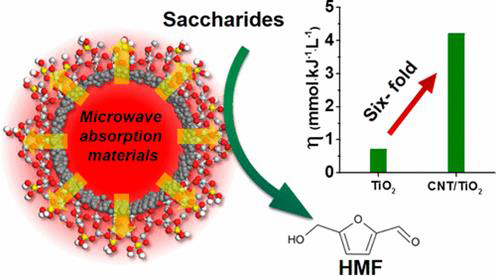

Figure 2. Boosting energy efficiency of nickel cobaltite via interfacial engineering in cotton fibric derived electrically conductive carbon fabric.

Hybrid electrodes with electroactive components on conductive substrates have been demonstrated effective strategy to achieve high energy and power density in supercapacitors. However, the mismatch of interface property could be a huge hurdle to further improve energy storage performance and long-term stability. Here, an interfacial metal seeding approach has been developed targeting strengthening of the interfacial interaction between electroactive NiCo2O4 nanostructure and carbon substrate as well as to promote electron transfer across the interface. By implanting low-concentration nickel (Ni) nanoparticles at the interface, the electrochemical capacitance of NiCo2O4 was boosted up to 2367 F/g at a current density of 1 A/g, which is about 2 times higher than the capacitance obtained from the electrode without metal seeds. The Ni seeds also contribute to an excellent cycling retention of >96% after 5000 cycles, where only 65% capacitance was retained in the electrode without Ni seeds.

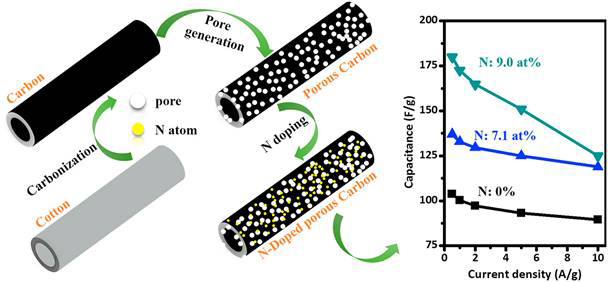

Figure 3. Cotton fabric derived hierarchically porous carbon and nitrogen doping for sustainable capacitor electrode.

Cotton fabric has been processed into hierarchically porous carbon with a two-step chemical-free method, i.e. carbonization in nitrogen and controlled thermal oxidation in air. By optimizing thermal oxidation temperature, large surface area of 777 m2/g could be achieved in cotton fabric derived carbon. The processed carbon remained the micron-meter tubular structure (same as cotton fiber), while meso-/micro-pores were also generated on tube wall. This uniquely structured porous carbon was then doped with nitrogen via a thermal pyrolysis process by using melamine as nitrogen source. The nitrogen content in the doped porous carbon could reach up to 9.0 atom% without sacrificing the porous structure and surface area. The nitrogen doping significantly improved the electrochemical capacitance up to 180 F/g at 0.5 A/g, which is 74% enhancement compared to the nitrogen-free carbon (104 F/g). Both origin carbon and nitrogen doped carbon show excellent cycling stability that 95% of the capacitance could be remained after 5,000 charge-discharge cycles.

(2) Microwave-responsive catalysts for energy efficient biomass conversion

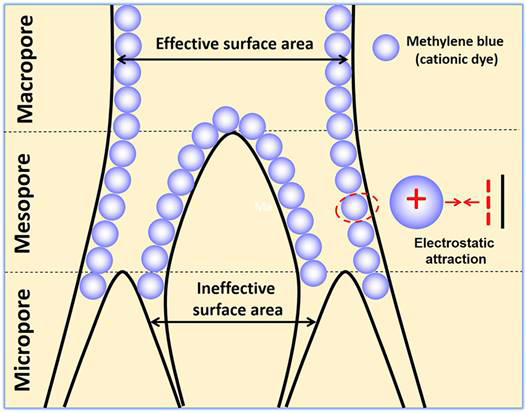

Figure 4. Enhancing energy efficiency in saccharide-HMF conversion with core/shell Structured microwave responsive catalysts.

Core/shell structured microwave responsive catalysts with carbon nanotube (CNT) core and acidified TiO2 shell were synthesized for catalytic conversion of saccharide to 5-hydroxymethylfurfural (HMF). With such a structure of inner microwave absorber and outer catalyst shell, the heat generated at the core area by microwave radiation can be translated to the shell catalyst directly. Such localized heating allows maximum heat utilization in the reaction and enhances the energy efficiency of the catalytic reaction. The energy efficiency of HMF formation reaches up to 4.2 mol·kJ–1·L–1 by using CNT/TiO2 catalyst, which is six-times higher compared to pure TiO2. These catalysts have been demonstrated effective in the hydrolysis conversion of various saccharides, such as fructose, glucose, and sucrose.

In a separately study, microwave absorption and catalytic activity have been synergistically integrated into a core/shell structured CNT/polyaniline (PANI) hybrid catalyst. Results reveal that the integration of CNT and PANI significantly improves the overall saccharide conversion and HMF yield. A thinner and rougher PANI shell is favorable to enhance the overall microwave absorption, improve heat transfer efficiency to catalyst surface and thus reaction efficiency. The highest energy efficiency of 7.6 mmol kJ−1 L−1 is reached with CNT/PANI catalyst. This work opens a new window in microwave responsive catalyst design that enhances energy efficiency in saccharide-HMF conversion reactions and promotes the economic feasibility of such reactions in practice.

(3) Impacts

This fund has been used to support graduate students working on biomass carbon project as well as catalytic biomass conversion project. This project will be extended for one more year for further exploring the potential of such technologies in wider applications. By working on this project, the student received tremendous training on literature review, experimental design, materials fabrication, catalytic reaction operation, data analysis and scientific paper writing. More importantly, the gained knowledge, learned lab skills and published work all prepare the student for a future professional career. To the PI, this is the first external fund in his career. Besides the fully completion of the proposed tasks, this fund allows PI to explore new opportunities in related research areas and generate preliminary results for federal grants. Based on the preliminary results, the PI has developed a NSF proposal on the topic of sustainable lubricants by using green biomass as lubricating additives and his career proposal on the topic of microwave responsive catalysts.