Reports: ND852387-ND8: Pressurized Hydraulic Fracturing of the Devonian Marcellus Shale with Liquid CO2: Impact on Enhanced Gas Recovery

Alan J. Kaufman, PhD, University of Maryland

Wenlu Zhu, PhD, University of Maryland

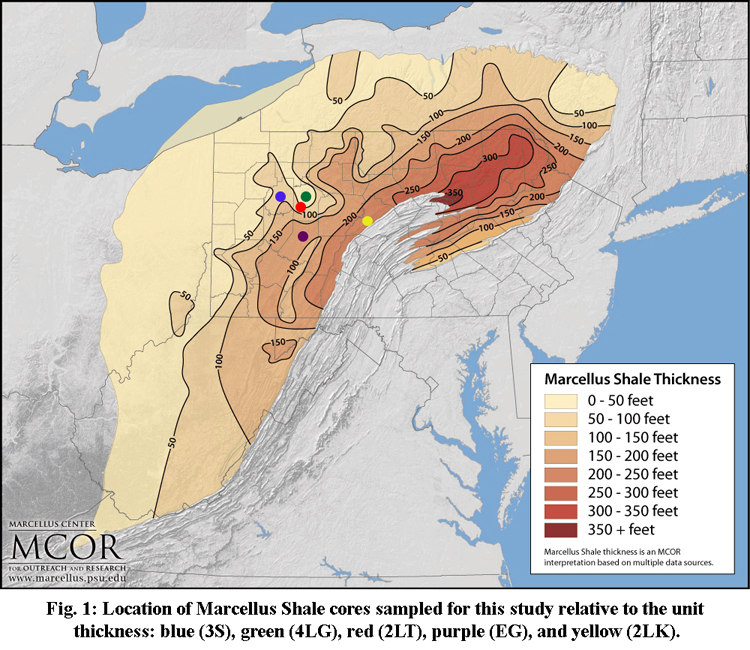

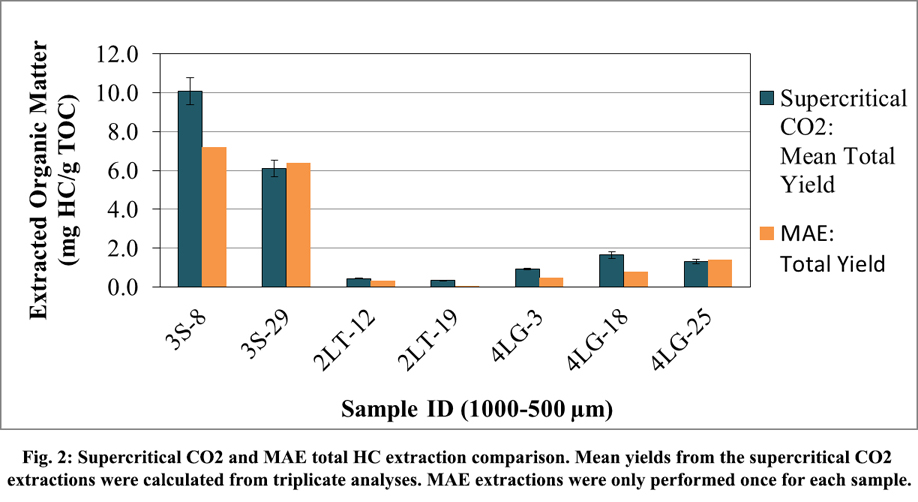

Seven specimens were selected for further study after assessment of resource potential by Rock-Eval, LECO, and reflectance analysis. These samples were further characterized for 13C contents of total organic carbon and for bulk mineralogy by XRD. Supercritical CO2 extractions at 80 oC and 21.7 MPa were conducted with an ISCO SFX 220 instrument at the USGS in Reston, Virginia revealing an overall range of resolvable n-aliphatic hydrocarbons spanning from n-C11 through n-C21, but with variation in these ranges between cores and unresolved complex mixtures of longer-chained hydrocarbons in some samples. The attenuated range of hydrocarbons coupled with Rock-Eval and reflectance analyses confirms the high level of thermal maturity of the cores associated with deep burial. The abundance of total extractable hydrocarbons (ranging between 0.3 to 12 mg HC/g total organic carbon) determined by supercritical CO2extractions were comparable to those extracted by standard microwave assisted techniques with a CEM MARS X system using 50/50 acetone/dichloromethane (Fig. 2).

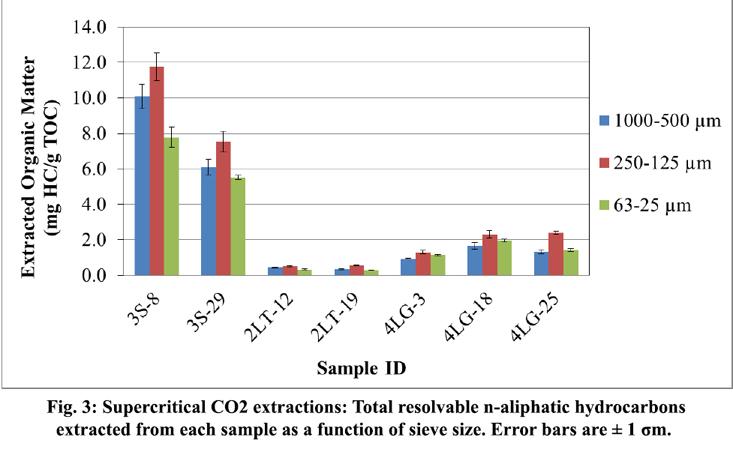

Total extractable hydrocarbons in Marcellus samples were evaluated as a function of matrix particle size (Fig. 3). Contrary to expectations, decreasing particle size (considering sieve fractions 1,000 - 500 µm, 250 - 125 µm, and 63 - 25 µm) did not enhance hydrocarbon extraction. Subsequent Brunauer-Emmett-Teller surface area results revealed no significant variation in exposed sample surface area among these sieve fractions. Additionally, SEM images confirm that sieve size is not an accurate indication of the grain size distribution. Nonetheless, overall trends in hydrocarbon recovery were observed among all samples, including: 1) recovery reaches a maximum in the intermediate 250 - 125 µm size fraction; 2) recovery increases as a function of S1 peak height (free HC content) and specific surface area, regardless of sieve size; and 3) no simple combination of parameters such as organic matter content, mineralogy, or pore structure dictate total yields.

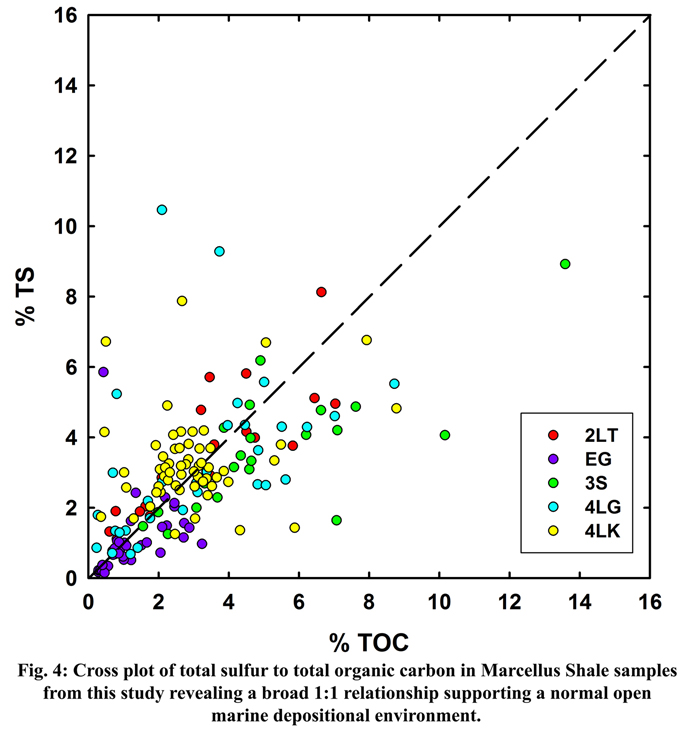

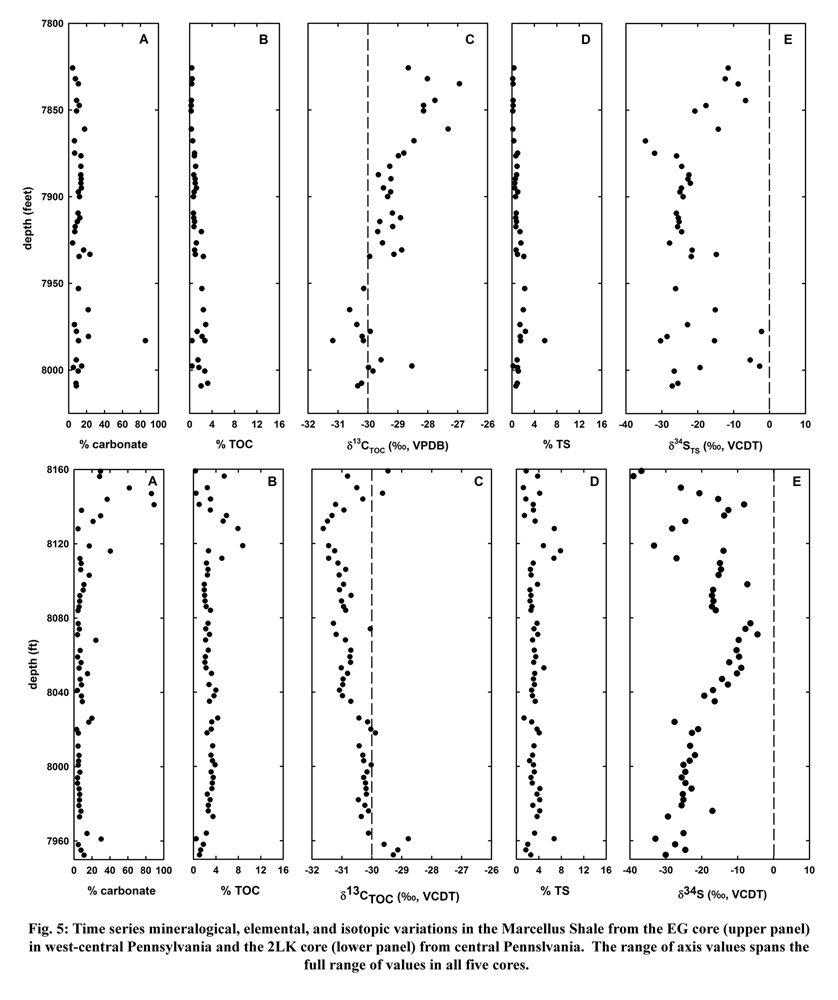

Variations in quantity of recoverable hydrocarbons among different cores may be related to the content of organic matter and other mineral constituents in the core samples, as well as the porosity of the shale and exposed surface area. To further characterize the sedimentological and geochemical aspects of the cores we conducted high resolution analyses of the percent of carbonate, total organic carbon (TOC), and total sulfur (TS), as well as the carbon (d13CTOC) and sulfur isotope (d34STS) compositions of organic matter and pyrite, respectively. Total organic carbon and total sulfur abundances are similar in the Marcellus core samples supporting an open marine depositional setting (Fig. 4).

The time-series data reveal stratigraphic trends of environmental significance. In the four western cores where the Marcellus ranges from 100-150 feet thick, there is an up section decline in TOC and TS abundances and an increase of 13CTOC (Fig. 5 upper panel from the EG core). Sulfur isotope compositions of pyrite in these cores are strongly depleted in 34S, but are generally variable and reveal no clear stratigraphic trends. In contrast, the Marcellus is thicker in central Pennsylvania (where the unit is more deeply buried and thermally mature), where TOC and TS abundances are relatively constant (except in a narrow window centered around 8120 feet depth) and there is a significant up section decline in 13CTOC (Fig. 5 lower panel from the 2LK core). While d34S values in this core are similar to those in the west, there is a strong stratigraphic trend to 34S enrichment in its lower reaches. Overall, the d13CTOCcompositions are noted to decline with increasing TOC abundances. The temporal and spatial variations revealed in these cores likely reflect changes in the source of organic matter during deposition of the Marcellus Shale, with the more negative carbon and sulfur isotope values reflecting more open marine conditions.

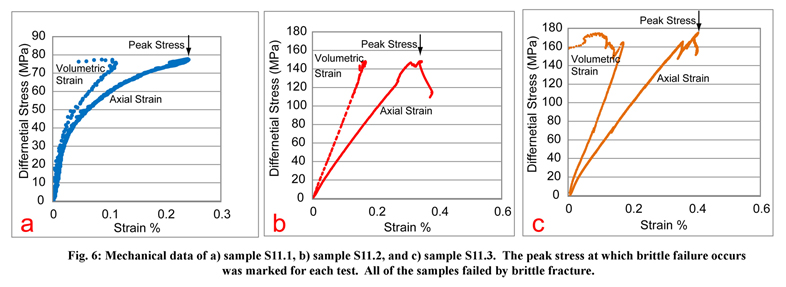

Porosity and permeability measurements (with an ULTRAPore He porosimeter and an ULTRAPerm N2 permeameter, respectively) as well as hydro-mechanical deformation experiments on a typical sample were conducted to further characterize the Marcellus Shale. Deformation tests on the Marcellus sample (cored at three different angles relative to bedding) were performed using an Autolab1500 apparatus. Samples S11.1 and S11.2 were deformed at a confining pressure of 15MPa, and a strain rate of 1x10‑6 /s. Sample S11.3 was deformed at a confining pressure of 30MPa, corresponds to the in-situ effective stress at the depth at which the drill core was taken. The strain rate for S11.3 test is 1x10‑6/s (Fig. 6).

The mechanical data show that shear strength and elastic moduli of the Marcellus samples depend strongly on bedding laminations. At the same confining pressure and strain rate, the deformation data show that the shear strength of the bedding parallel sample S11.2 is only ~1/3 of that of the bedding perpendicular sample S11.1. Fractured samples were retrieved and measured for porosity and permeability after the deformation tests. To test the pressure dependence of permeability, measurements were conducted at different pressures during both loading and unloading cycles. Compared to the permeability values of respective undeformed samples, more than two orders of magnitude permeability increase was observed in the mechanically fractured samples. Micro-structure observations show that crack growth in the deformed Marcellus samples is controlled by the interplay between stress, laminations, and the contrast in strength between silt- and clay-rich layers. The stress-induced cracks are generally sub-parallel to the maximum principal stress. Changes in crack orientation are observed along bedding laminates and clay minerals.