Reports: ND752997-ND7: Oil Water Separations from Zone Annealed Block Copolymer Films

Alamgir Karim, PhD, University of Akron

General Approach: Diblock copolymers have ability to self-assemble into periodic microdomain structures that can be potentially applied as effective membranes for oil-water separation. We focus on the cylindrical nanoscale morphology as the etchable minority phase. An important aspect of the project concerns accomplishing directed self-assembly for vertical orientation control of domains and selective etchability of the minority phase domain for nanoporosity with high uniformity, with tunable pore size in the range of (15-60) nm for BCPs, and ultrahigh pore density up to 1010 pores / cm2. This can satisfy important membrane requirements such as high selectivity and high throughput (HS/HT).

Experimental Aspects:

Materials: The sample of poly(styrene-block-methylmethacrylate) (PS-b-PMMA) (Mw=57k-b-25k) was bought from Polymer Source Inc. and used as is. The composition ratio of polymer chain lengths (volume fraction of the PS block is ~0.7) leads to forming a cylindrical morphology. The cylinder spacing L0≈50nm. Homopolymer poly-methylemthacrylate (PMMA) of molecular weight 25,000 and polystyrene of molecular weight 58,000 purchased from Polymer Source Inc. was used as is.

Samples:

Table I Different content of BCP based sample composition in toluene

| Sample | Content | Molecular weight | r |

|---|---|---|---|

| 1 | BCP | 57K-b-25K | |

| 2 | BCP +1%PMMA | 57K-b-25K+25K | 1 |

| 3 | BCP +5%PMMA | 57K-b-25K+25K | 1 |

| 4 | BCP+10%PMMA | 57K-b-25K+25K | 1 |

| 5 | BCP+15%PMMA | 57K-b-25K+25K | 1 |

| 6 | BCP+20%PMMA | 57K-b-25K+25K | 1 |

| 7 | BCP+1%PS | 57K-b-25K+56K | 1 |

| 8 | BCP+5%PS | 57K-b-25K+56K | 1 |

| 9 | BCP+10%PS | 57K-b-25K+56K | 1 |

| 10 | BCP+15%PS | 57K-b-25K+56K | 1 |

| 11 | BCP+20%PS | 57K-b-25K+56K | 1 |

*BCP refers to PS-b-PMMA; r is ratio of molecular weight of homopolymer over relative component in block copolymer.

The above BCP and homopolymer mixed films were flow-coated onto quartz substrates with different thickness range by varying flow-coating speed. Film thicknesses were measured by a thin film interferometer, (F-20 UV Thin Film Analyzer, Filmetrics, Inc.).

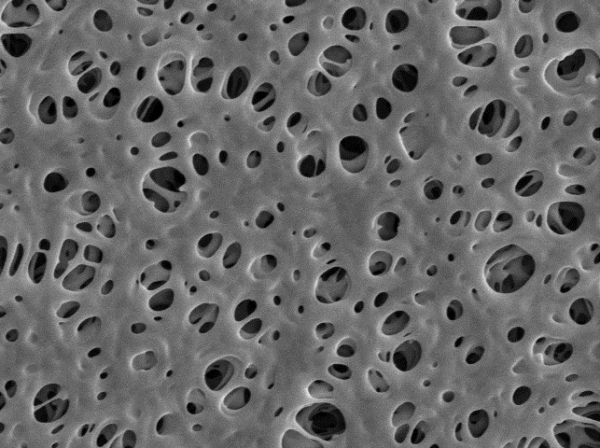

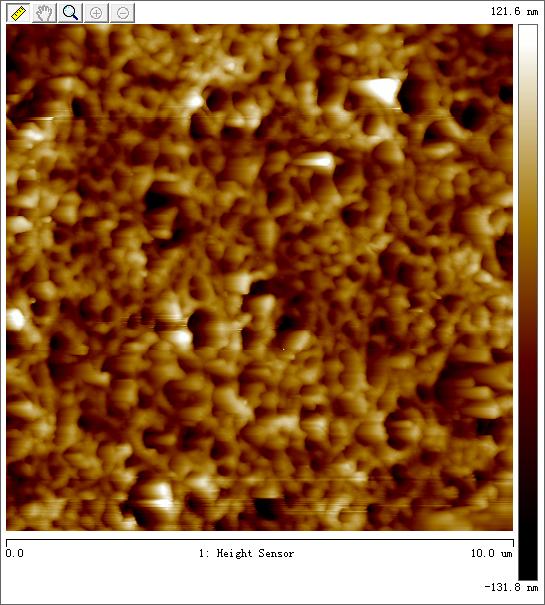

Supporting membrane: Sterlitech Polyethersulfone (PES) membranes are hydrophilic filters constructed from pure polyethersulfone and available in pore sizes ranging from 0.03 micron to 5.0 micron (Figure 1).

Figure 1. SEM of morphology of PES supporting membranes (left) and AFM height sensor image of surface of the PEO membranes (right).

Key Results and Discussion:

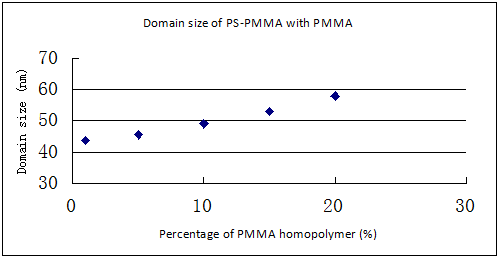

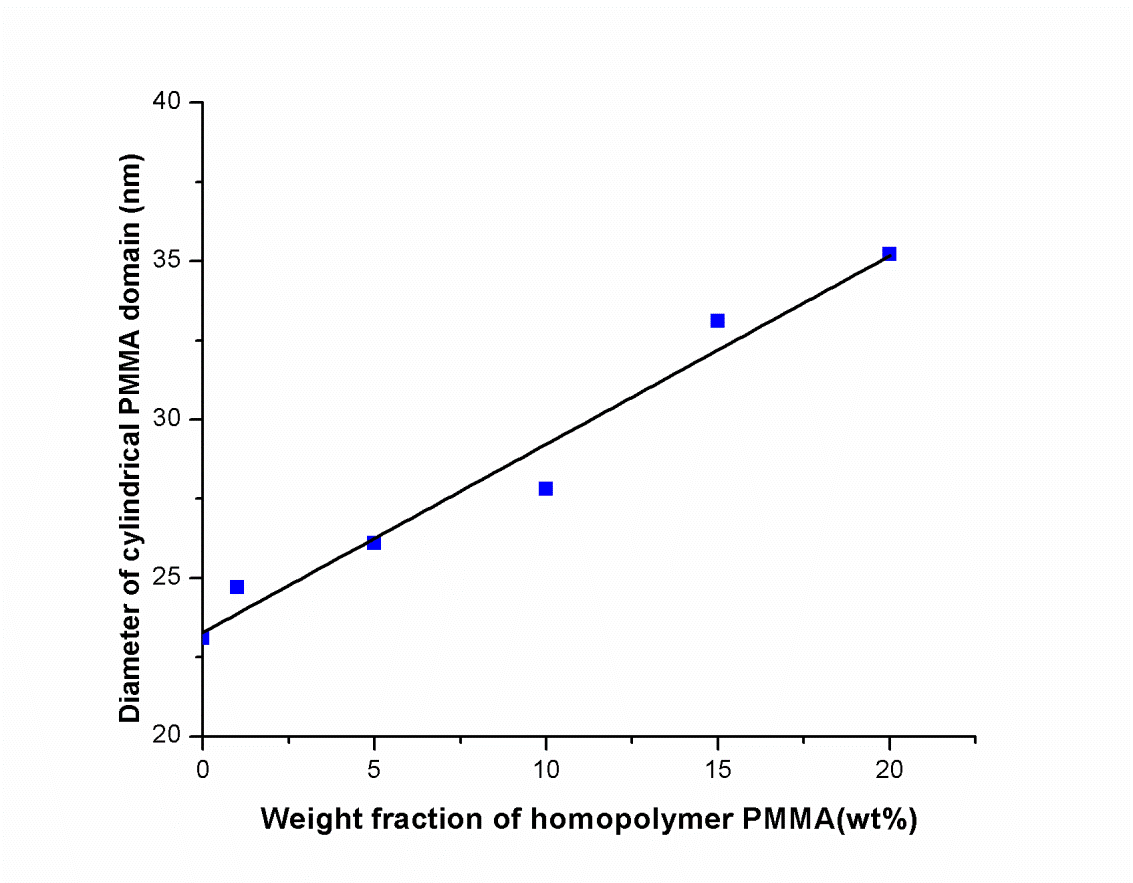

BCP with blended homopolymer: By blending PMMA homopolymer to PS-b-PMMA BCP, we could control the diameter of the vertical cylinder. Table 2 documents domain size vs. blending PMMA homopolymer content. Figure 2. shows swelling is linear with homopolymer addition.

Table II The domain size of different percentage of PMMA homopolymer

| Content % PMMA | Domain Size (nm) | Domain Swelling (%) |

|---|---|---|

| 1 | 43.73 | 4.86 |

| 5 | 45.55 | 9.23 |

| 10 | 49.08 | 17.69 |

| 15 | 52.94 | 26.95 |

| 20 | 57.92 | 38.89 |

Figure 2. Domain size variation as function of percentage of PMMA homopolymer.

CZA-S ordered BCP films:

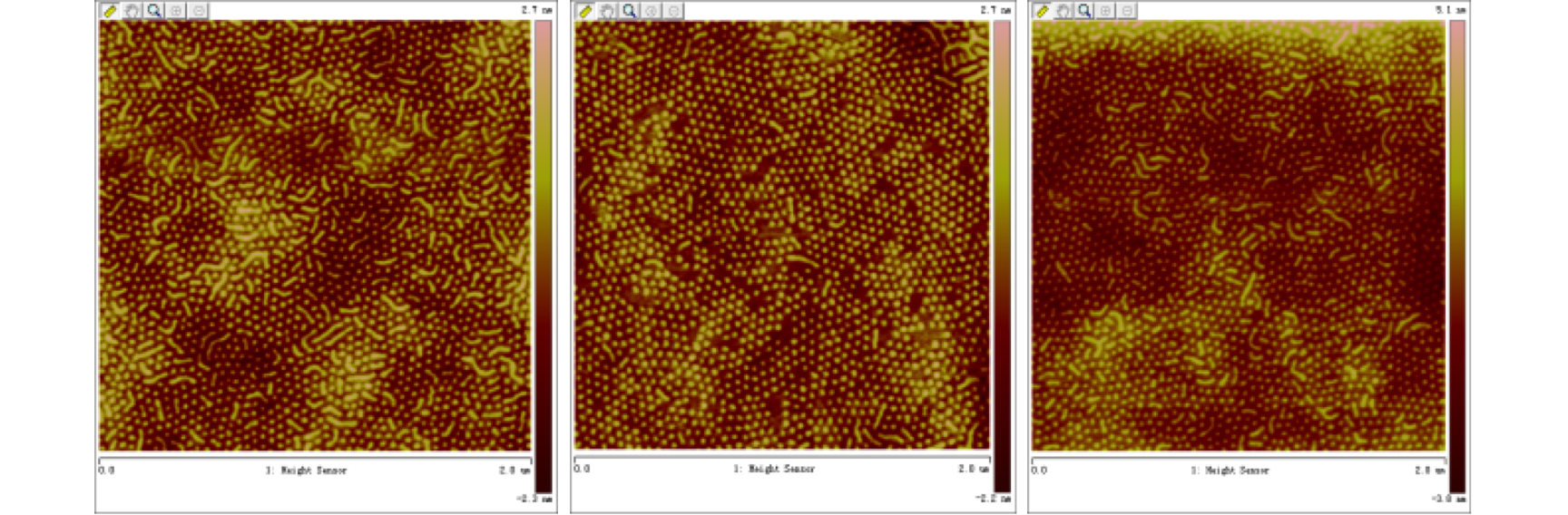

Next we examine ordering of PS-b-PMMA films with CZA-S. Figure 3. shows effect of PS-b-PMMA film thickness on vertical order as processed by CZA-S.

Figure 3. AFM images of CZA-S annealed (Tmax=210 °C, 10μm/s, 35 °Cmm-1) PS-PMMA thin films with different thickness: Left=70 nm, Center =100, and Right=85 nm. Scan size is 2μm.

Table III. CZA-S PS-b-PMMA BCP film characteristics with different thickness

| Thickness (nm) | % Perpendicular Cylinders | Density of nanopores |

|---|---|---|

| 70 | 37.2% | 217.25/μm2 |

| 85 | 59.2% | 317.97/μm2 |

| 100 | 94.3% | 420.77/μm2 |

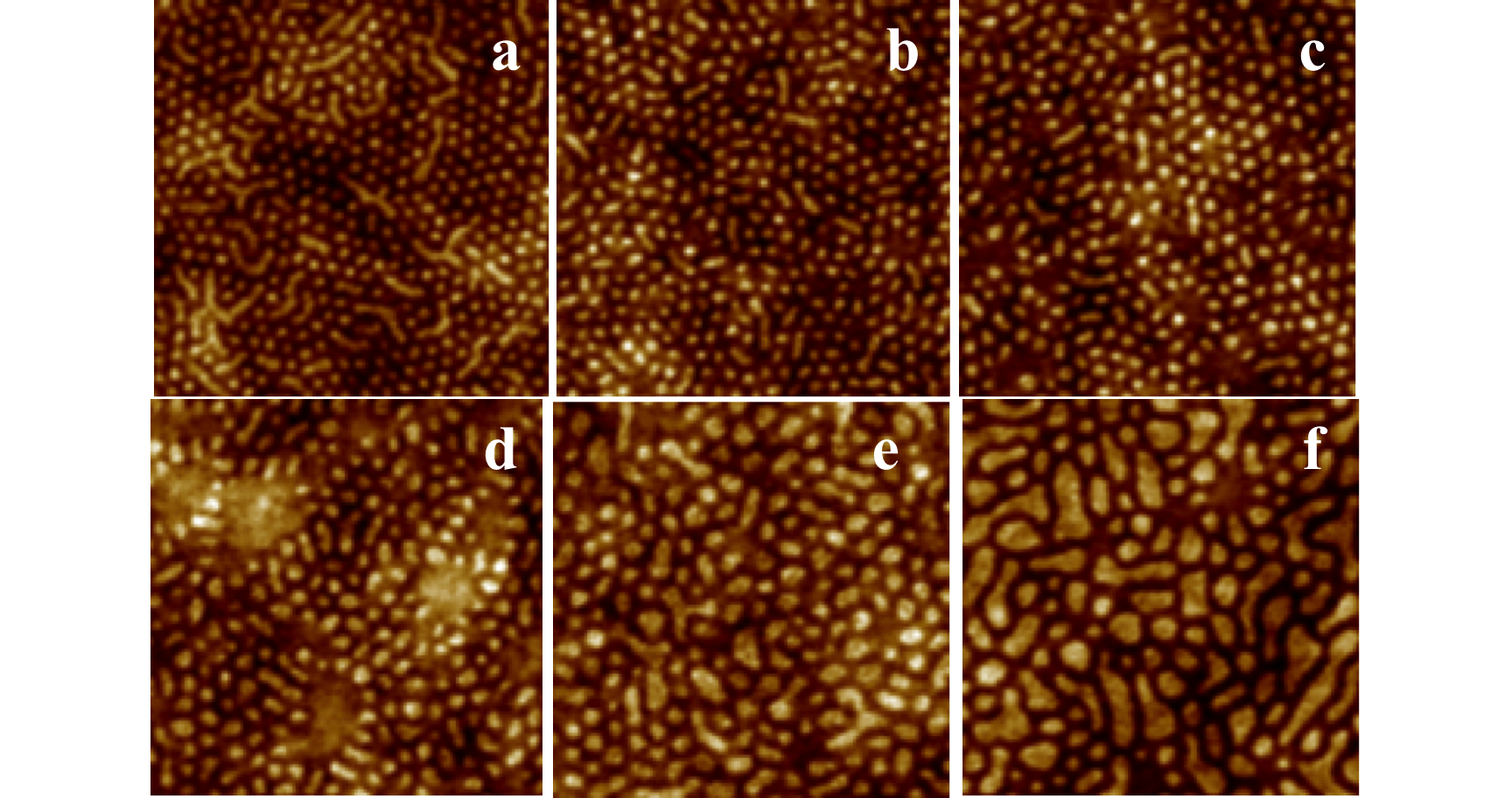

Clearly increasing the film thickness leads to a larger fraction of surface perpendicular cylinder fraction as a result of release from substrate pinning effect (wetting) on the attractive PMMA domain. Figure 4 shows the effect of CZA-S on PS-PMMA/PMMA homopolymer blend films, while Figure 5 shows that the equivalent diameter of the PMMA domains increase linearly.

Figure 4. AFM images of CZA-S annealed (Tmax=210 °C, 10μm/s and 35 °Cmm-1) PS-PMMA thin films with varying loading fractions of homopolymer PMMA (a) 1%, (b) 5%, (c) 10%, (d) 15%, (e) 20%, and (f) 30%. Scan size is 2μm.

Figure 5. Equivalent diameter of cylindrical PMMA domain in thin films of mixtures of PS-PMMA with various weight fraction of homopolymer PMMA after CZA-S annealed ((Tmax=210 °C, 10μm/s and 35 °Cmm-1)

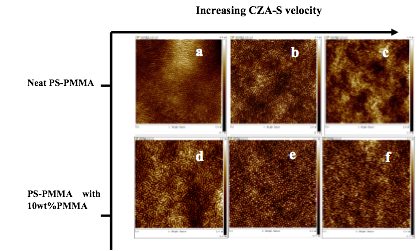

Figure 6. AFM images of CZA-S annealed neat PS-PMMA (a-c) and PS-PMMA/PMMA (10wt%) (d-f) with sample sweeping velocities of (a, d) 5μm/s, (b, e) 10μm/s and (c, f) 15μm/s. Scan size is 2μm.

Increasing CZA-S velocity has a positive effect on vertical orientation of PMMA domains with and without added homopolymer PMMA as shown in Figure 6, and UVO etched as in Figure 7.

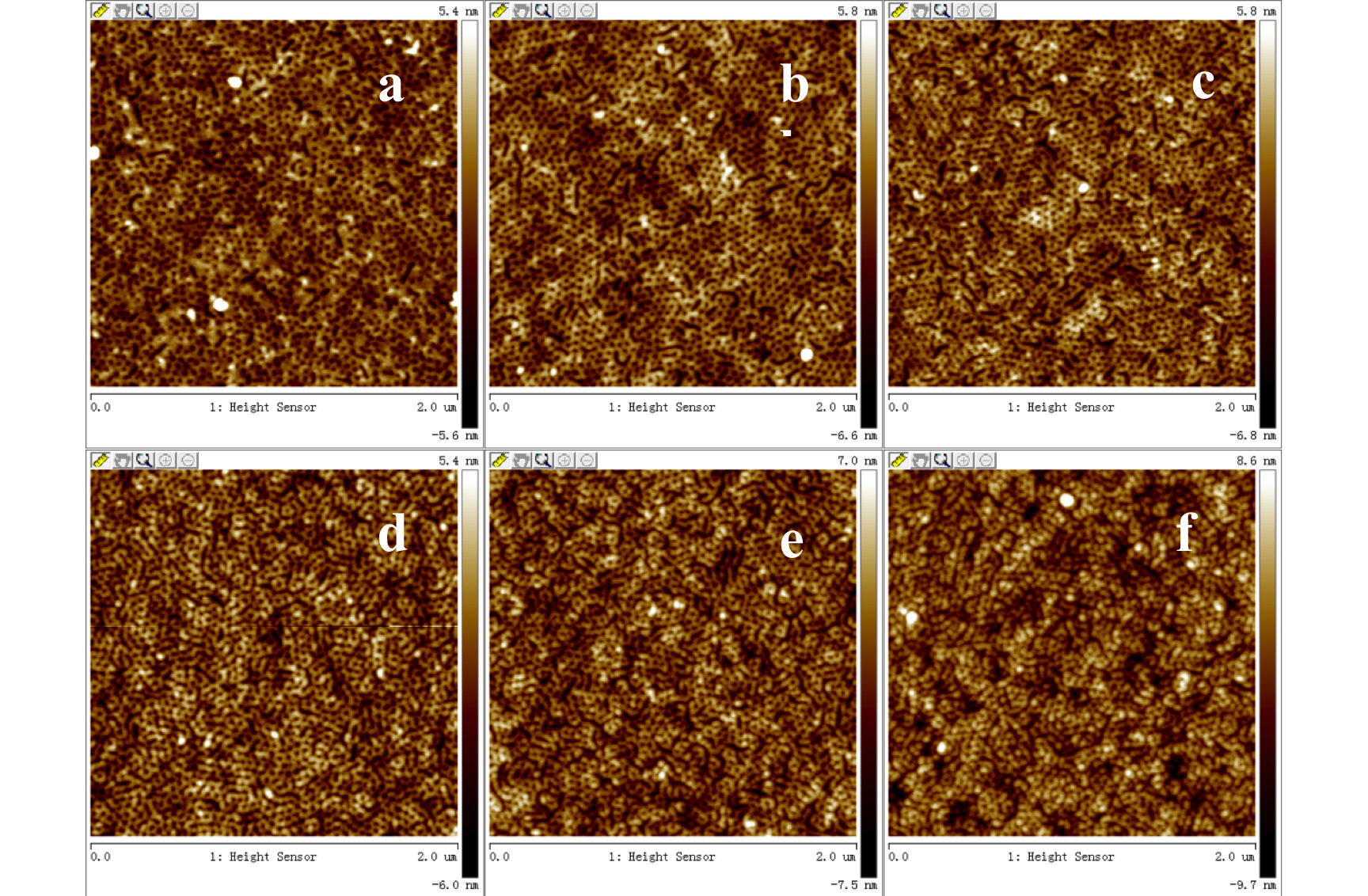

Figure 7. AFM images of PS-PMMA thin films with different etching time (a) 1h, (b) 1.5h, (c) 2h, (d) 2.5h, (e) 3h, and (f) 3.5h. These films were annealed by CZA-S at Tmax=210 °C, 10μm/s and 35 °Cmm-1 before etching.

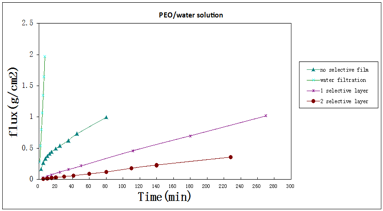

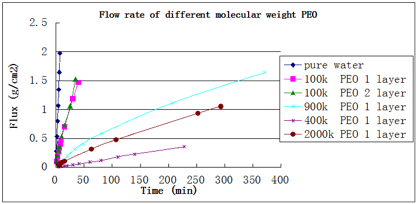

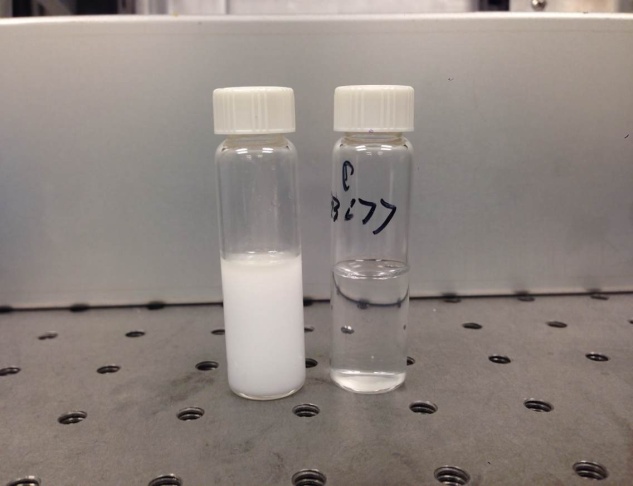

Preliminary Key Filtration Results: The etched BCP films were tested for filtration of PEO in water with successful results for PEO filtration (Figure 8,9) and oil-water separation (Figure 10.).

Figure 8. Flow rate of deionized(DI) water and PEO/DI water solution for PES, composite membranes with one and two selective nanoporous layers, respectively.

Figure 9. Flow rate of PEO with different molecular weight dissolved in DI water solution for composite membranes with one or two selective nanoporous layers, respectively.

Figure 10. Oil/water separation was achieved in BCP membranes where the membranes were intact over large areas. Images shows the cloudy oil-water emulsion and wateronly filtrate which is clear. The purity of the filtrate needs to be established.